Score

Showing 1–300 of 615 results

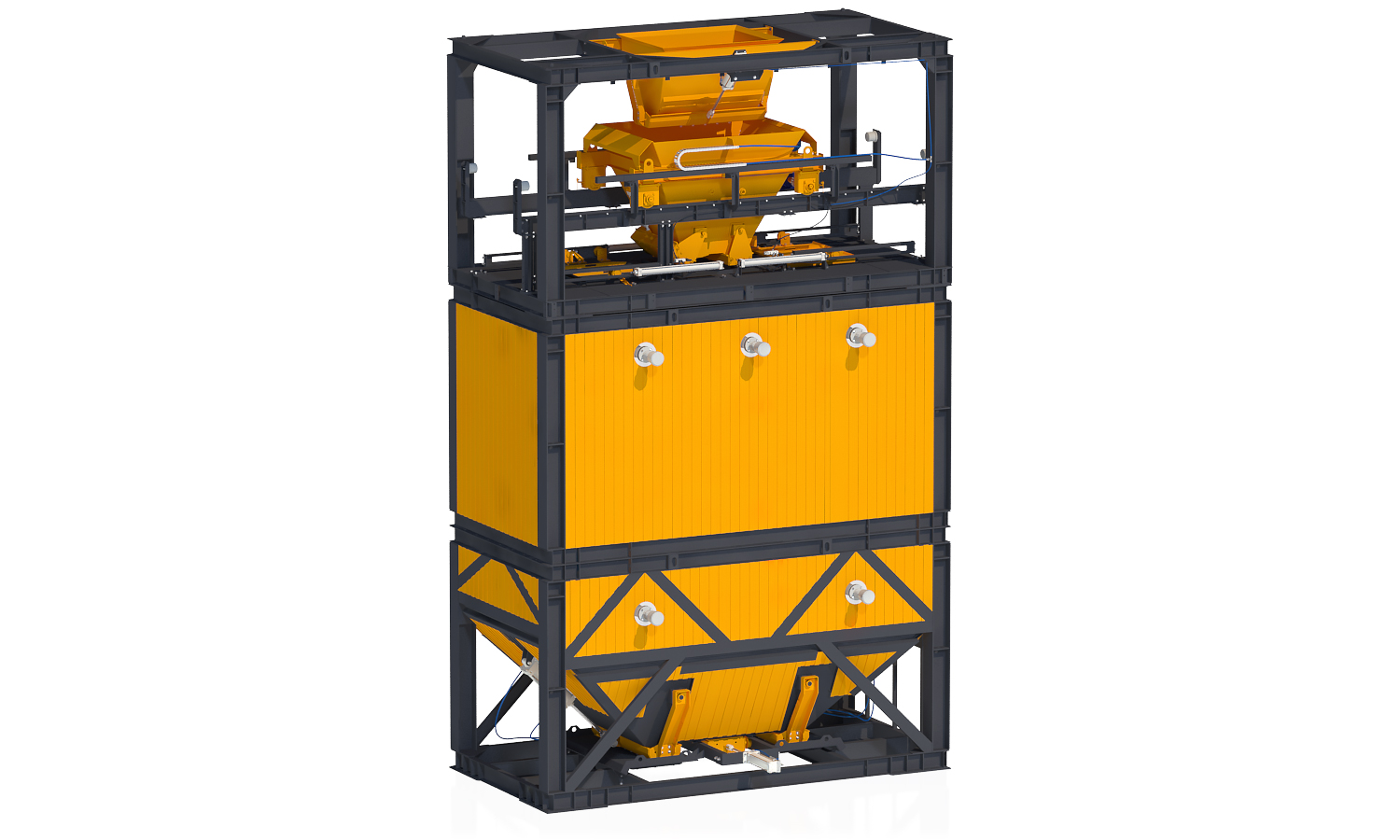

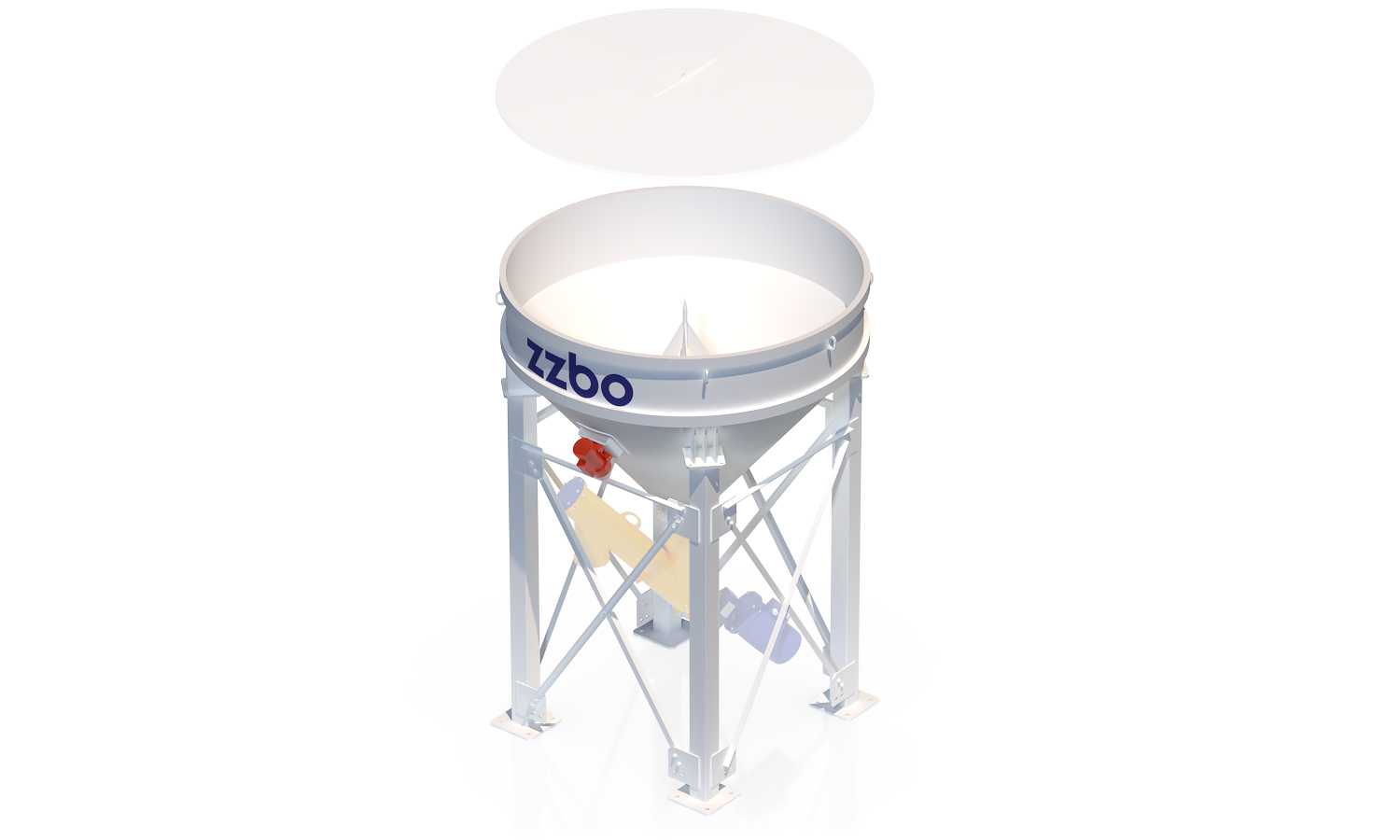

- Concrete plants SMART

- Soil mixing plants

- Receiver volume 200 l., pr-t 553 lmin

- Uncategorized

- Concrete plants QUICK BETON

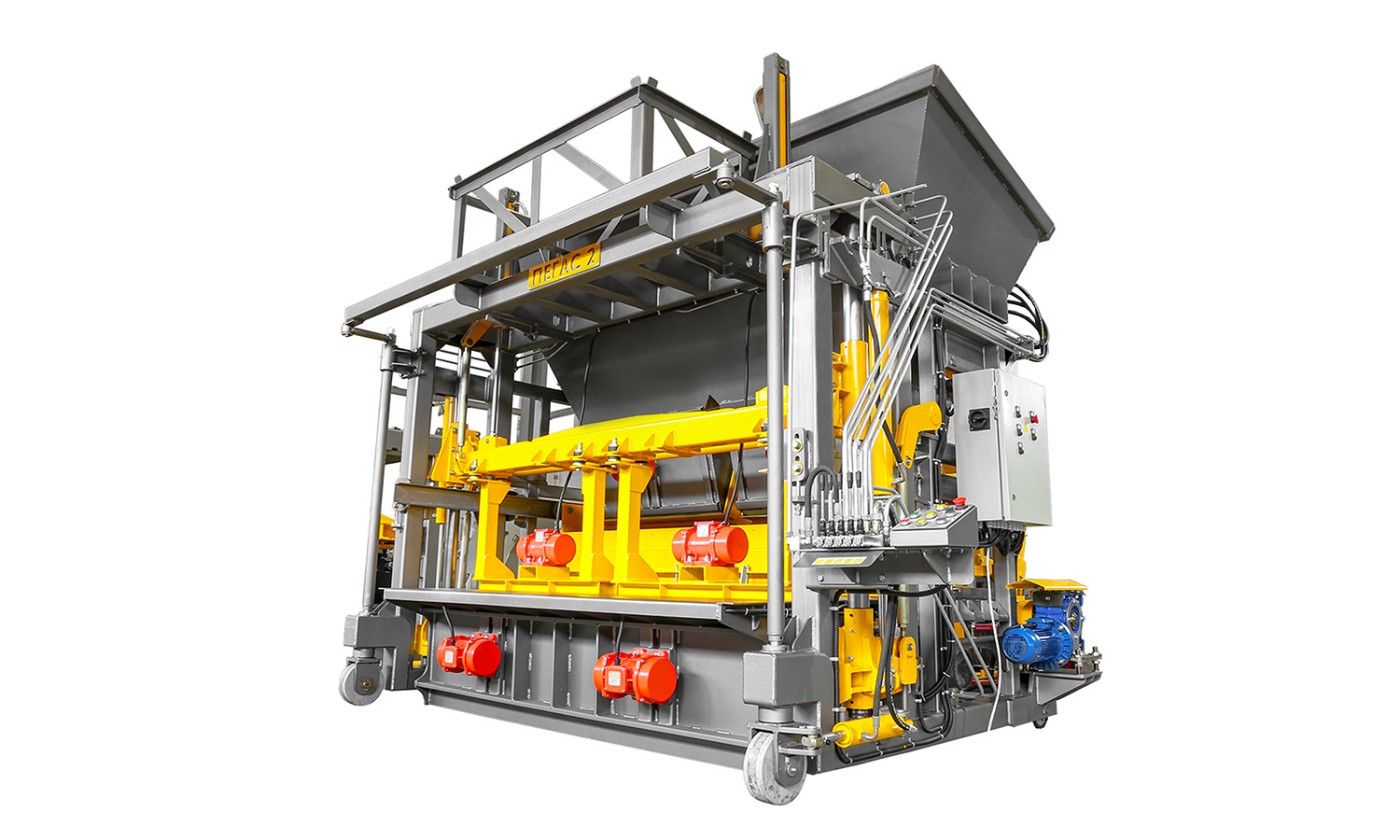

- Concrete plants and concrete for vibropresses

- Concrete plants for large-scale construction

- Concrete plants for a small construction

- Concrete plants for the implementation of concrete

- Basic equipment BMZ-80

- Bituminous economy

- Vibrating presses for concrete rings

- Service

- LENTA Concrete Plants

- Concrete plants MIXER

- MOBIL Concrete Plants

- SKIP Concrete Plants

- Winter concrete plants

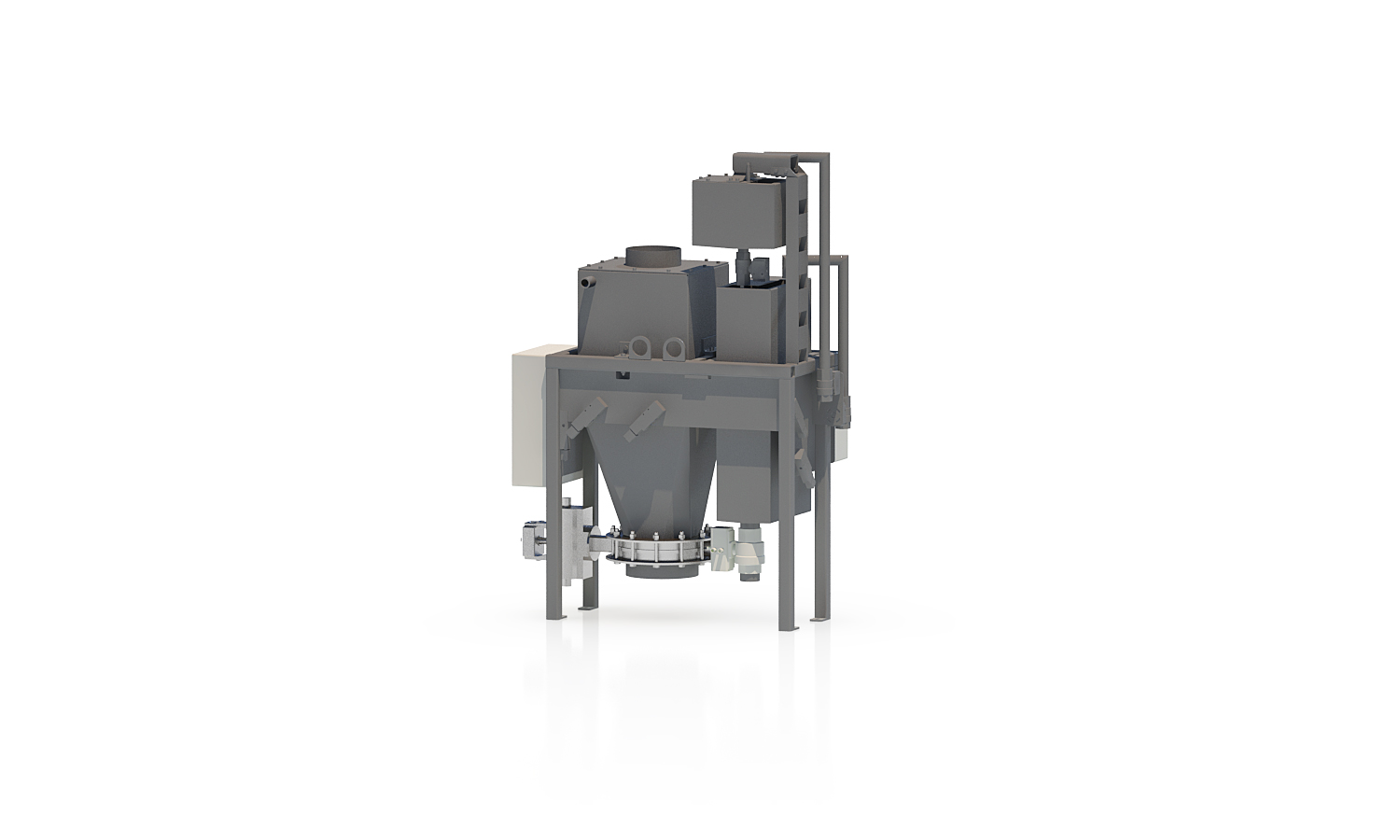

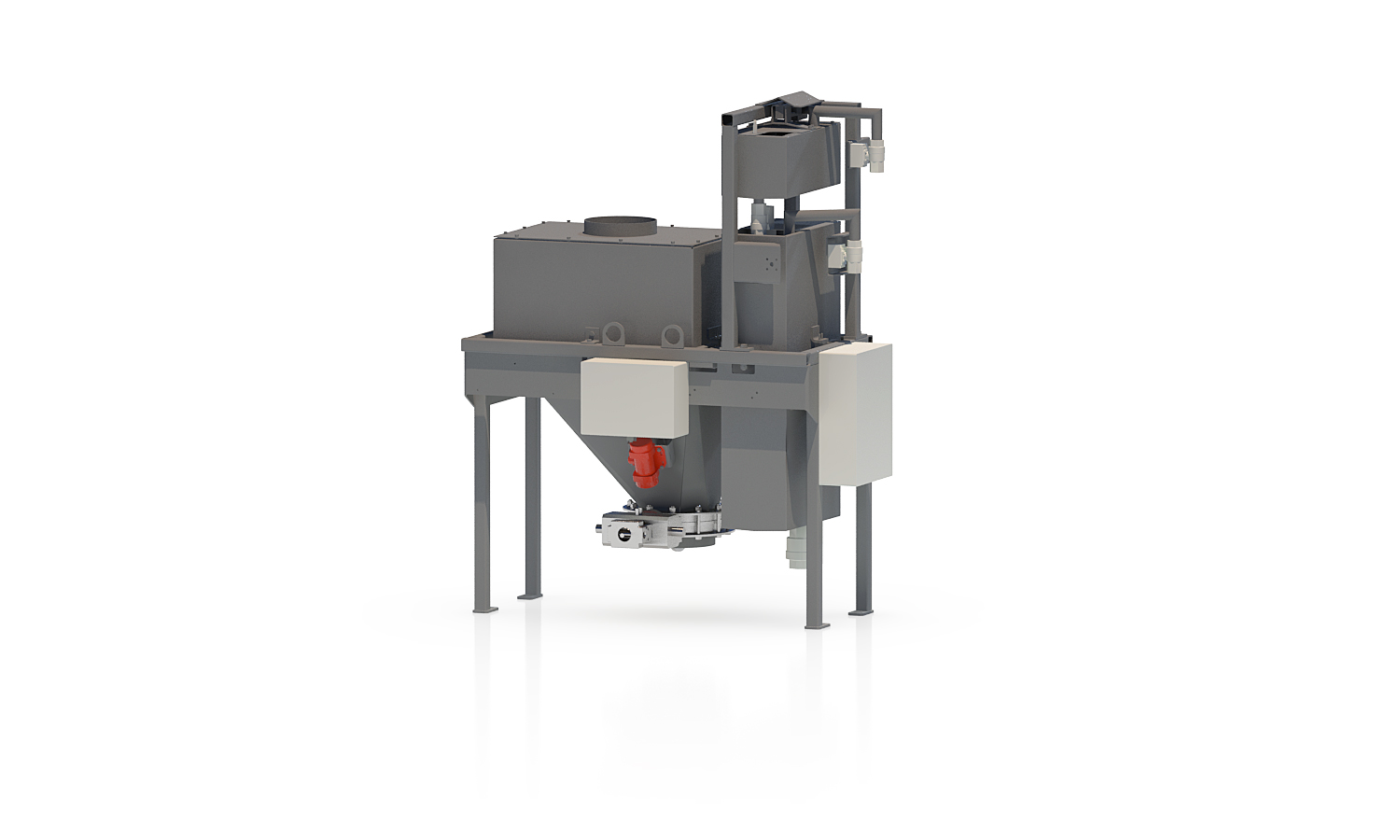

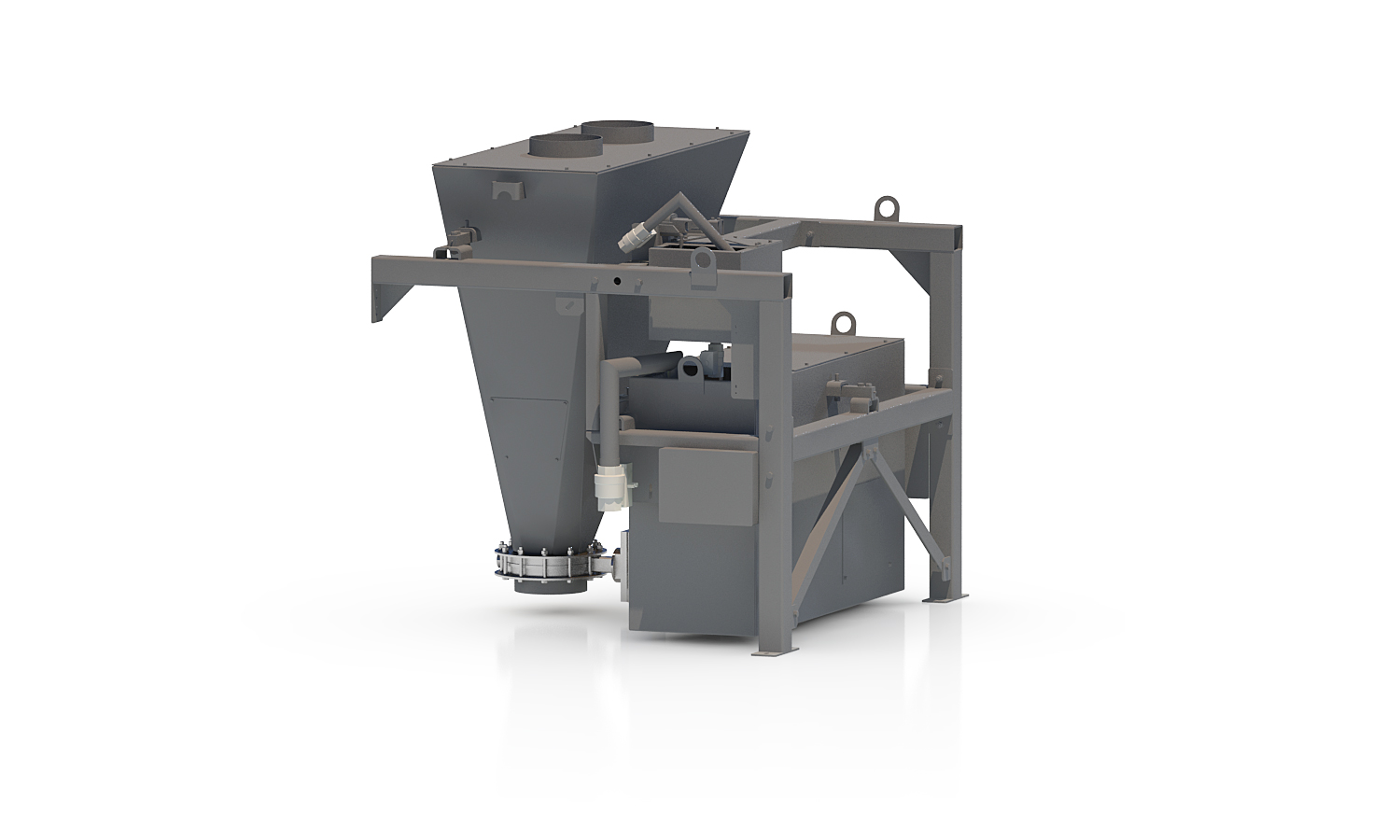

- Components for CBP

- Mini RBU

- Concrete plants COMPACT

70 900

- Объём бака, м3 0,4

- Расчётное давление под налив (0,01МПа)

- Расчётная температура стенки, °С +300

- Масса бака, кг 180

- Length, mm 1525

- Width, mm 678

- Height, mm 1280

87 500

- Объём бака, м3 1

- Расчётное давление под налив (0,01МПа)

- Расчётная температура стенки, °С +300

- Масса бака, кг 260

- Length, mm 2010

- Width, mm 800

- Height, mm 1408

104 200

- Объём бака, м3 1,5

- Расчётное давление под налив (0,01МПа)

- Расчётная температура стенки, °С +300

- Масса бака, кг 316

- Length, mm 2708

- Width, mm 800

- Height, mm 1408

116 700

- Объём бака, м3 2

- Расчётное давление под налив (0,01МПа)

- Расчётная температура стенки, °С +300

- Масса бака, кг 375

- Length, mm 2215

- Width, mm 1018

- Height, mm 1796

137 500

- Объём бака, м3 3

- Расчётное давление под налив (0,01МПа)

- Расчётная температура стенки, °С +300

- Масса бака, кг 480

- Length, mm 2950

- Width, mm 1018

- Height, mm 1800

73 500

- Изготавливаем из металла по Вашему выбору Hardox, Magstrong, 10ХСНД или 09Г2С

- Термообработка или цементирование on request

- Возможность изготовления сварная или цельнометаллическая

85 600

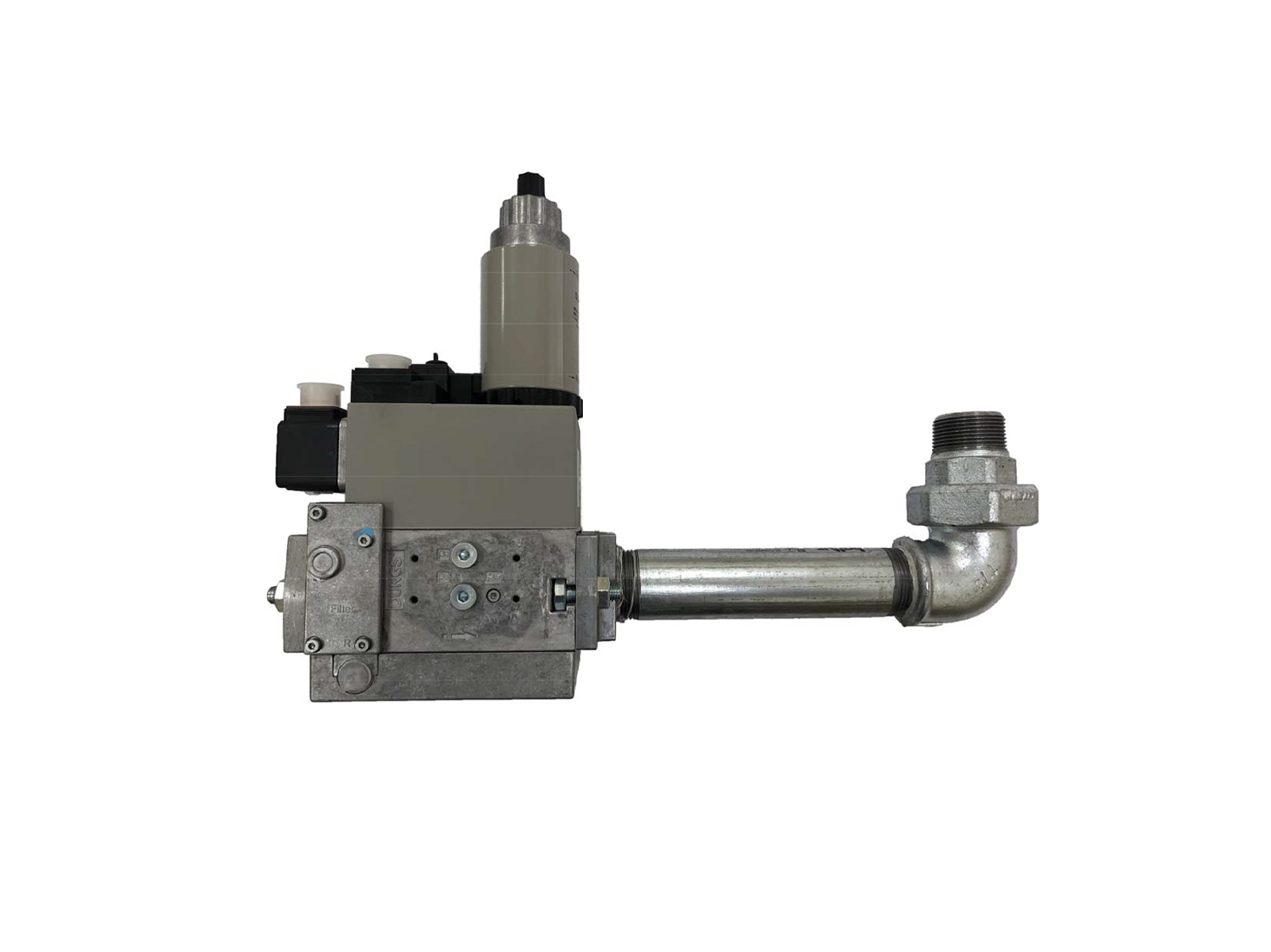

- Maximum operating pressure, mbar 360

- Outlet pressure range, mbar 4 – 20

- Operating ambient temperature, °C -15 ÷ +70

- Type of gas natural, liquefied

- Electrical equipment protection degree IP54

- Solenoid valve class class A, group 2

- Pressure stabilizer class class A, group 2

280 800

165 700

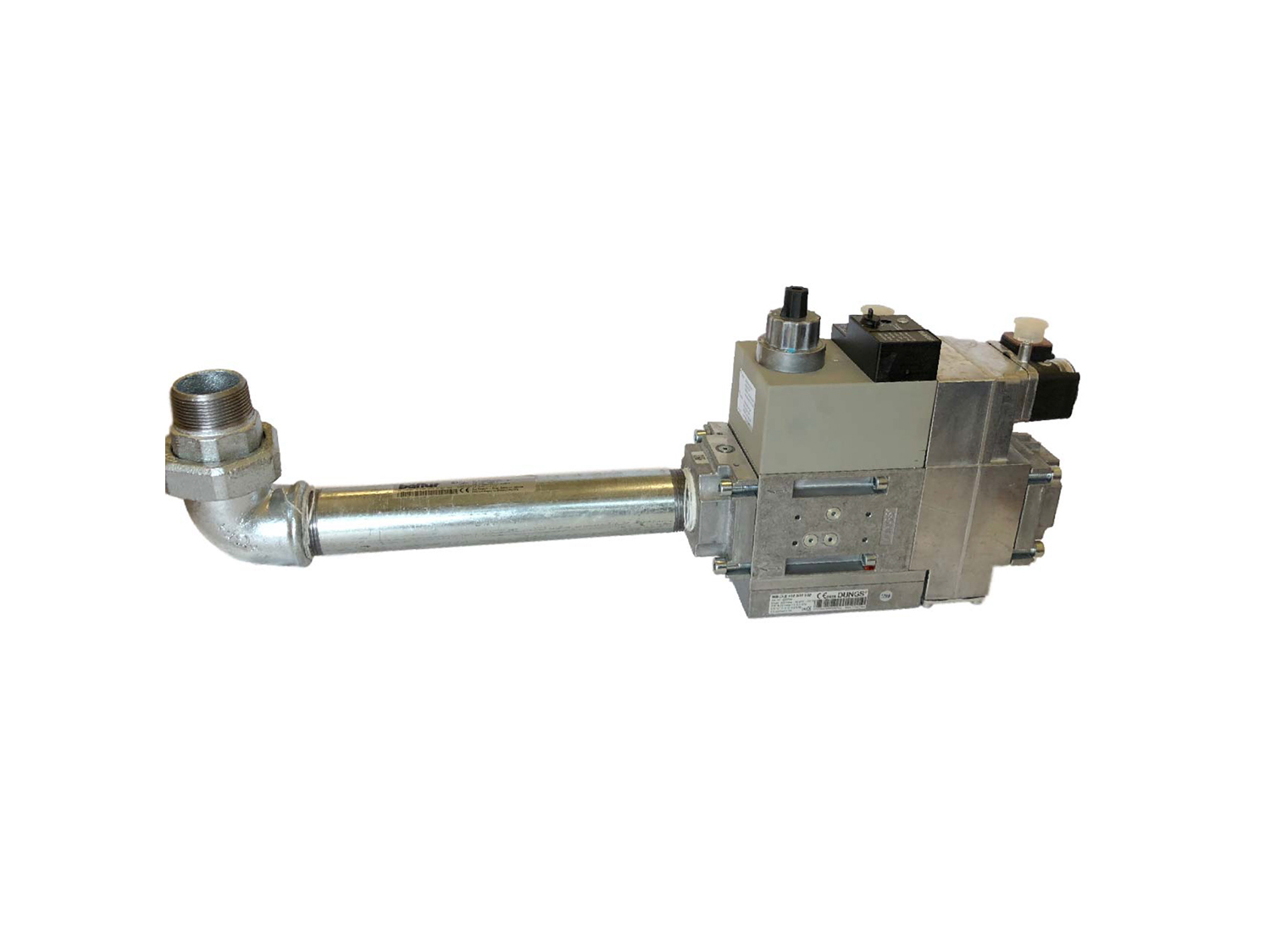

- Maximum operating pressure, mbar 360

- Outlet pressure range, mbar 4 – 20

- Operating ambient temperature, °C -15 ÷ +70

- Type of gas natural, liquefied

- Electrical equipment protection degree IP54

- Solenoid valve class class A, group 2

- Pressure stabilizer class class A, group 2

173 200

- Maximum operating pressure, mbar 360

- Outlet pressure range, mbar 4 – 20

- Operating ambient temperature, °C -15 ÷ +70

- Type of gas natural, liquefied

- Electrical equipment protection degree IP54

- Solenoid valve class class A, group 2

- Pressure stabilizer class class A, group 2

65 100

- Maximum operating pressure, mbar 360

- Outlet pressure range, mbar 4 – 20

- Operating ambient temperature, °C -15 ÷ +70

- Type of gas natural, liquefied

- Electrical equipment protection degree IP54

- Solenoid valve class class A, group 2

- Pressure stabilizer class class A, group 2

113 600

- Maximum operating pressure, mbar 360

- Outlet pressure range, mbar 4 – 20

- Operating ambient temperature, °C -15 ÷ +70

- Type of gas natural, liquefied

- Electrical equipment protection degree IP54

- Solenoid valve class class A, group 2

- Pressure stabilizer class class A, group 2

137 800

- Maximum operating pressure, mbar 360

- Outlet pressure range, mbar 4 – 20

- Operating ambient temperature, °C -15 ÷ +70

- Type of gas natural, liquefied

- Electrical equipment protection degree IP54

- Solenoid valve class class A, group 2

- Pressure stabilizer class class A, group 2

210 400

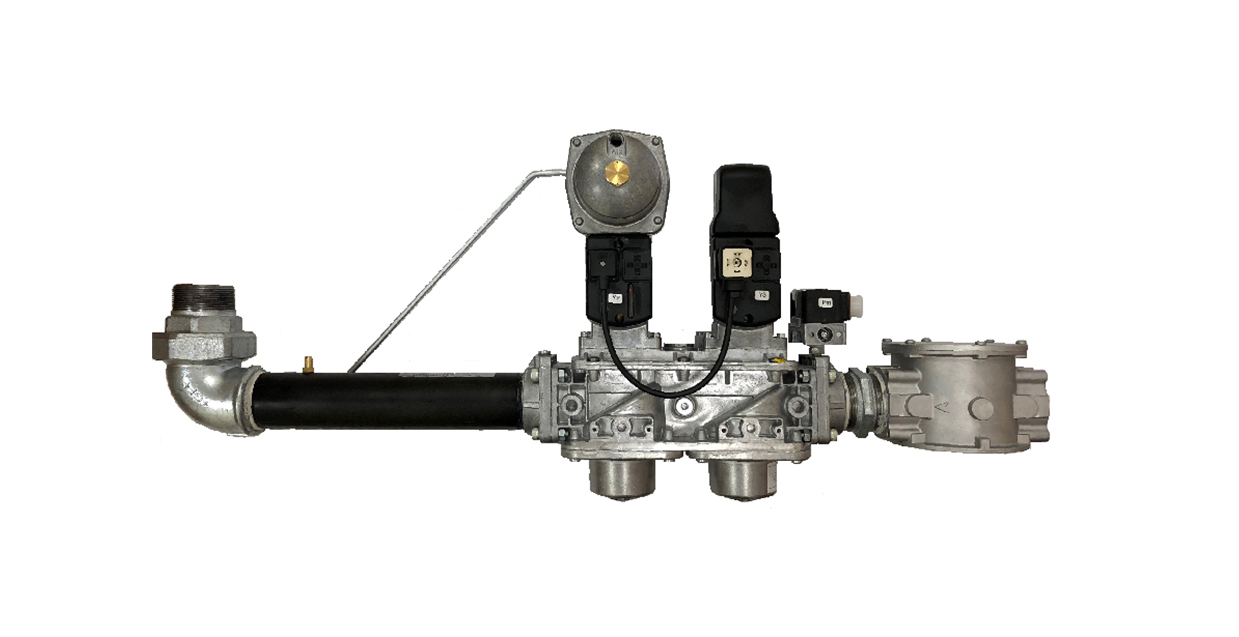

- Maximum operating pressure, mbar 500

- Outlet pressure range, mbar 15 – 120

- Operating ambient temperature, °C -10 ÷ +60

- Type of gas natural, liquefied

- Electrical equipment protection degree IP54

- Control valve type single stage

- Minimum gas pressure switch B (AC) 24 – 250

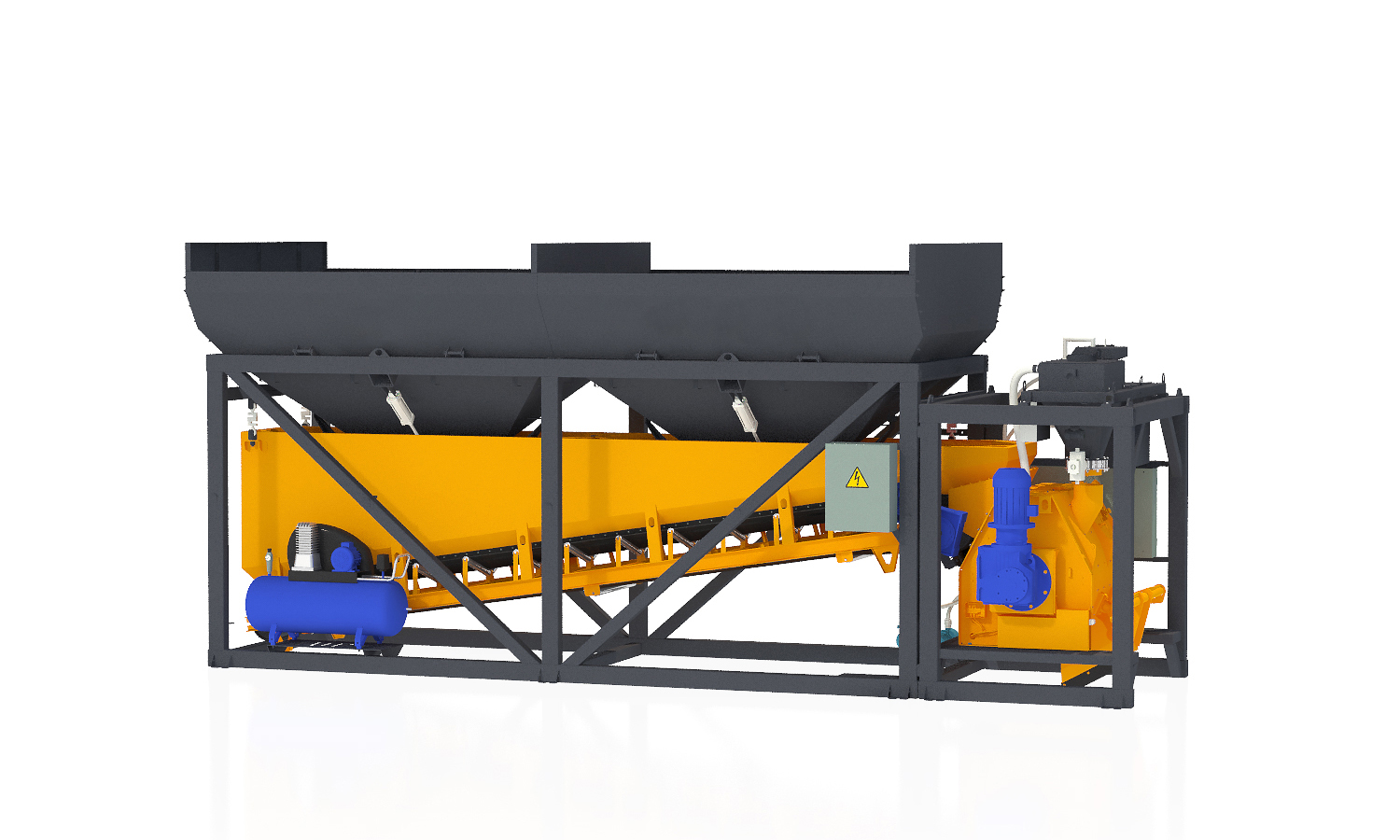

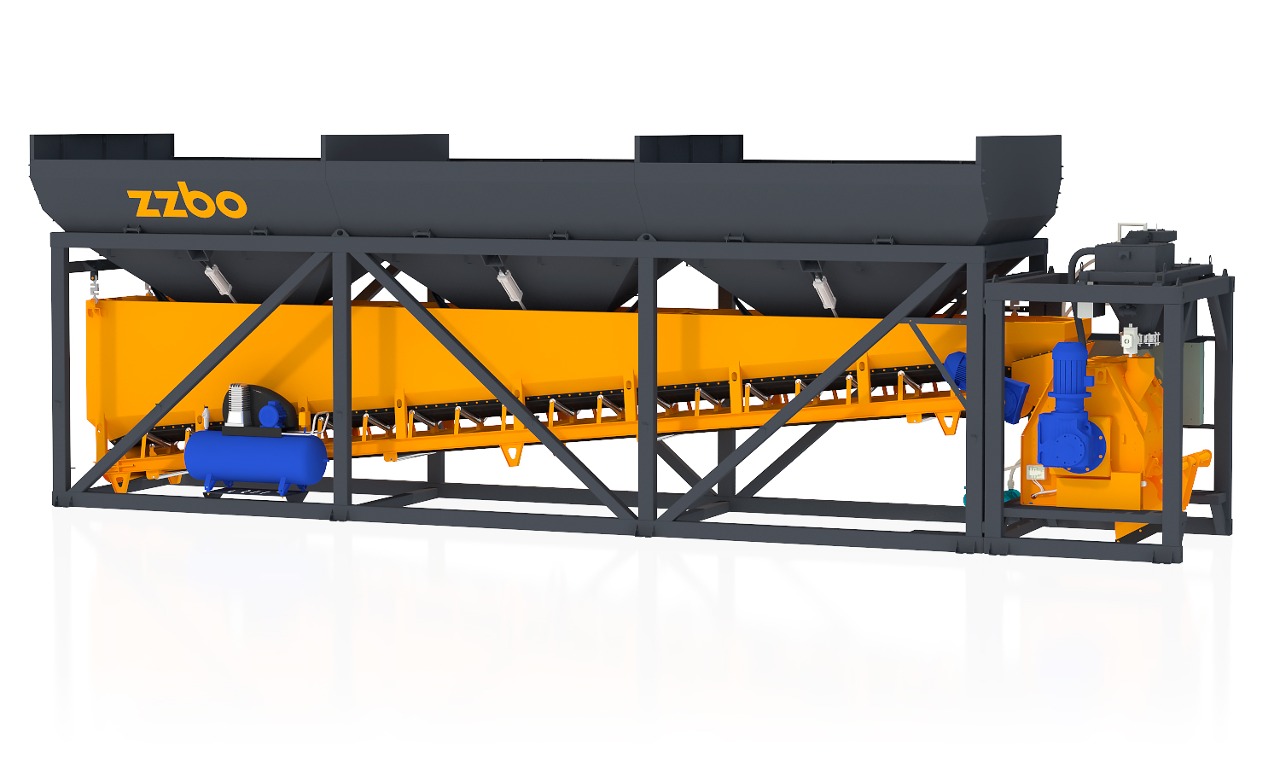

3 700 600

- Производительность, м³/час 10...20

- single-shaft mixer БП-1Г-500С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (2 х 8) = 16

- Total power, kW 23

- Weight, kg 5600

- Length, mm 7590

110 500

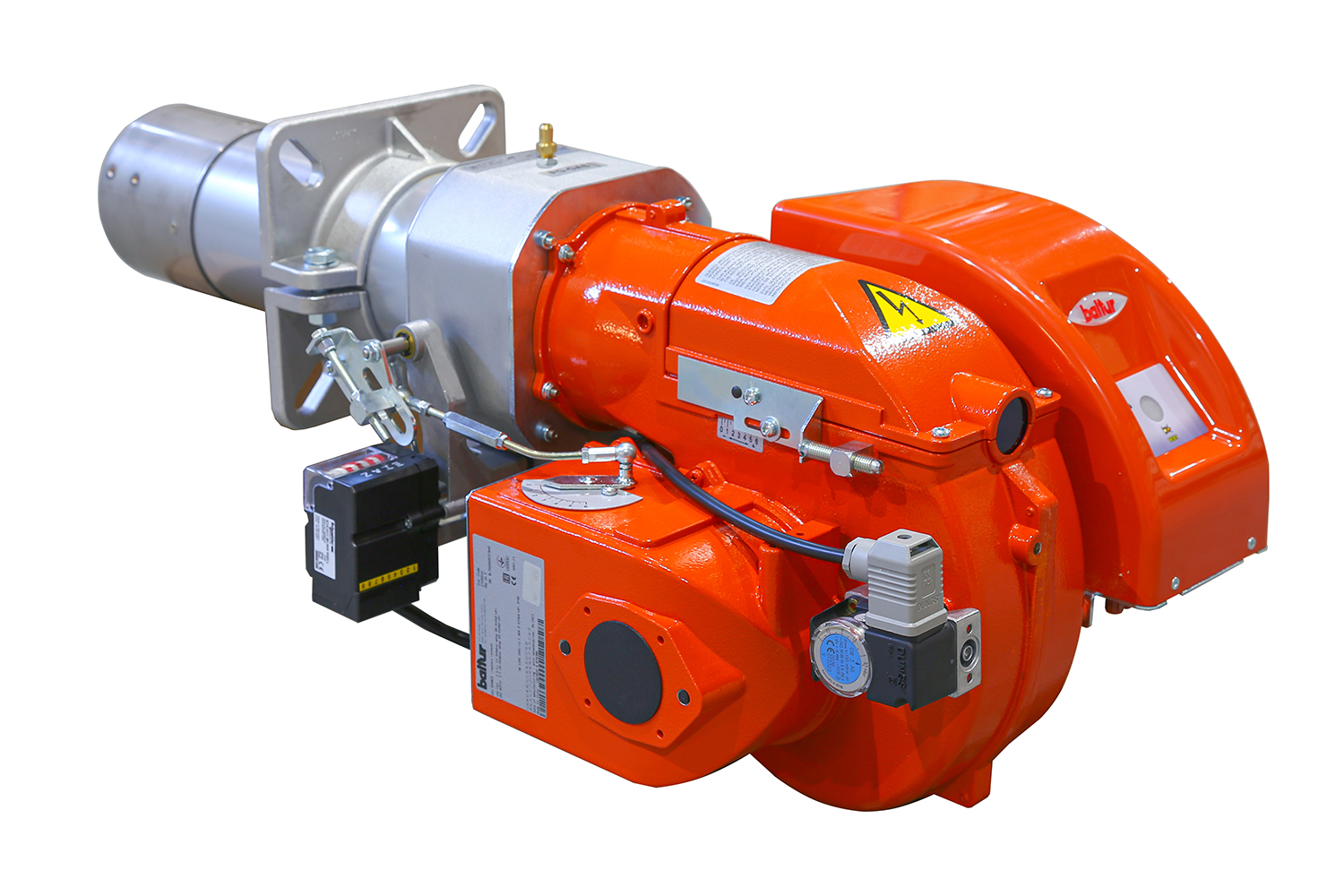

- power, kWt 50÷160

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Nitrogen oxide emissions 2nd grade

- Noise level, dB(A) 68

- Connecting gas fittings above

- Power supply, Hz ~1/220V/50

116 100

- power, kWt 60÷205

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Nitrogen oxide emissions 3rd grade

- Noise level, dB(A) 68

- Connecting gas fittings above

- Power supply, Hz ~1/220V/50

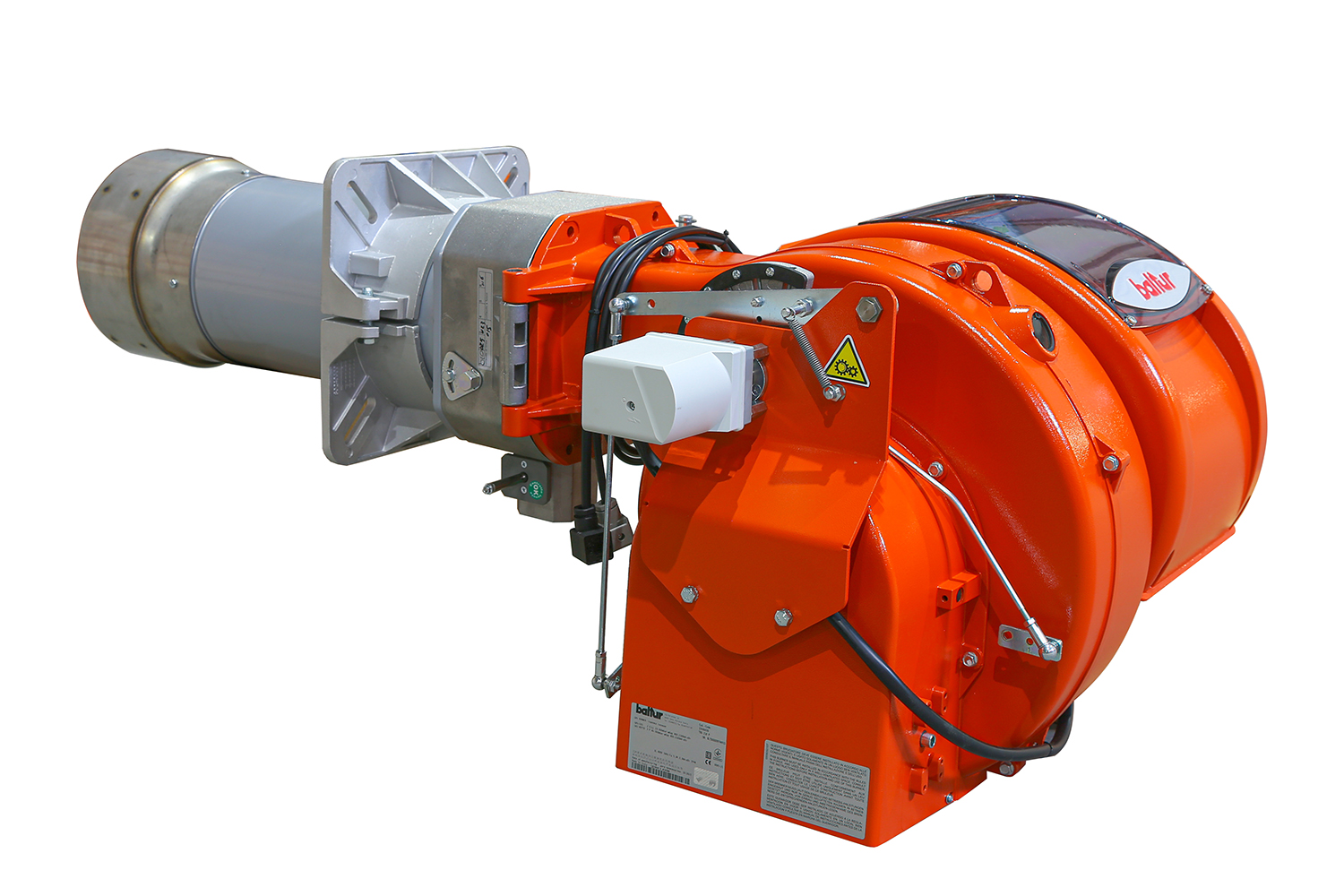

206 900

- power, kWt 80÷410

- Power regulation Smooth two-stage

- mode Intermittent (stop once every 24 hours)

- Nitrogen oxide emissions 3rd grade

- Noise level, dB(A) 77

- Connecting gas fittings from below

- Power supply, Hz ~1/220V/50

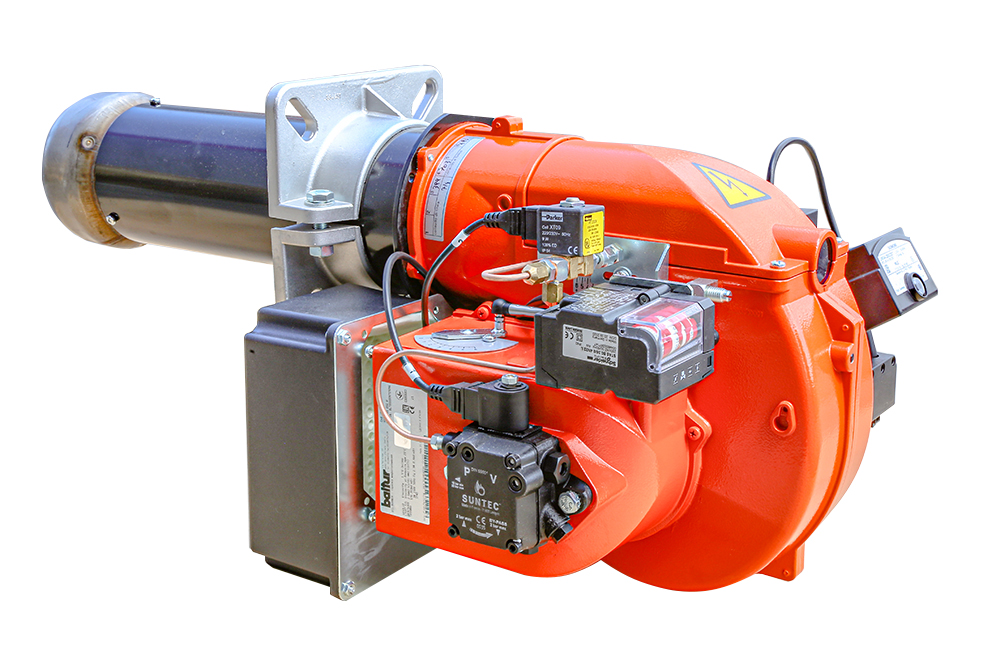

169 300

- power, kWt 178÷391

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Maximum fuel viscosity, cSt 6

- Diesel fuel atomization Mechanical

- Power supply, Hz ~1/220V/50

- Electrical protection degree IP40

289 500

- power, kWt 120÷600

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Nitrogen oxide emissions 3rd grade

- Noise level, dB(A) 76

- Connecting gas fittings bottom/top

- Power supply, Hz ~3/380V/50

203 800

- power, kWt 250÷600

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Maximum fuel viscosity, cSt 6

- Diesel fuel atomization Mechanical

- Power supply, Hz ~3/380V/50 Hz

- Electrical protection degree IP40

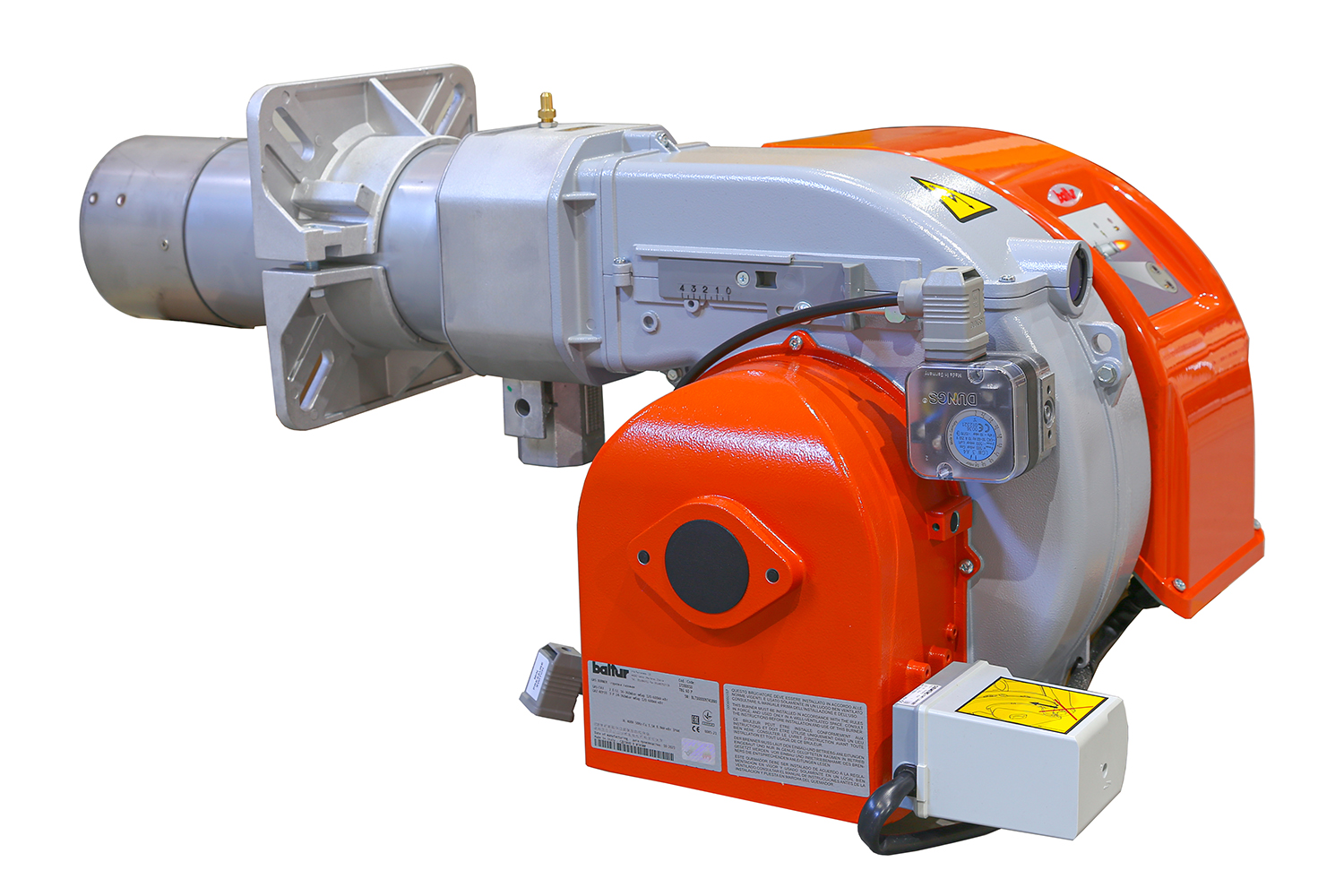

314 100

- power, kWt 170÷850

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Nitrogen oxide emissions 2nd grade

- Noise level, dB(A) 73

- Connecting gas fittings bottom/top

- Power supply, Hz ~3/380V/50

267 400

- power, kWt 200÷850

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Maximum fuel viscosity, cSt 6

- Diesel fuel atomization Mechanical

- Power supply, Hz ~3/380V/50 Hz

- Electrical protection degree IP40

370 500

- power, kWt 320÷1050

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

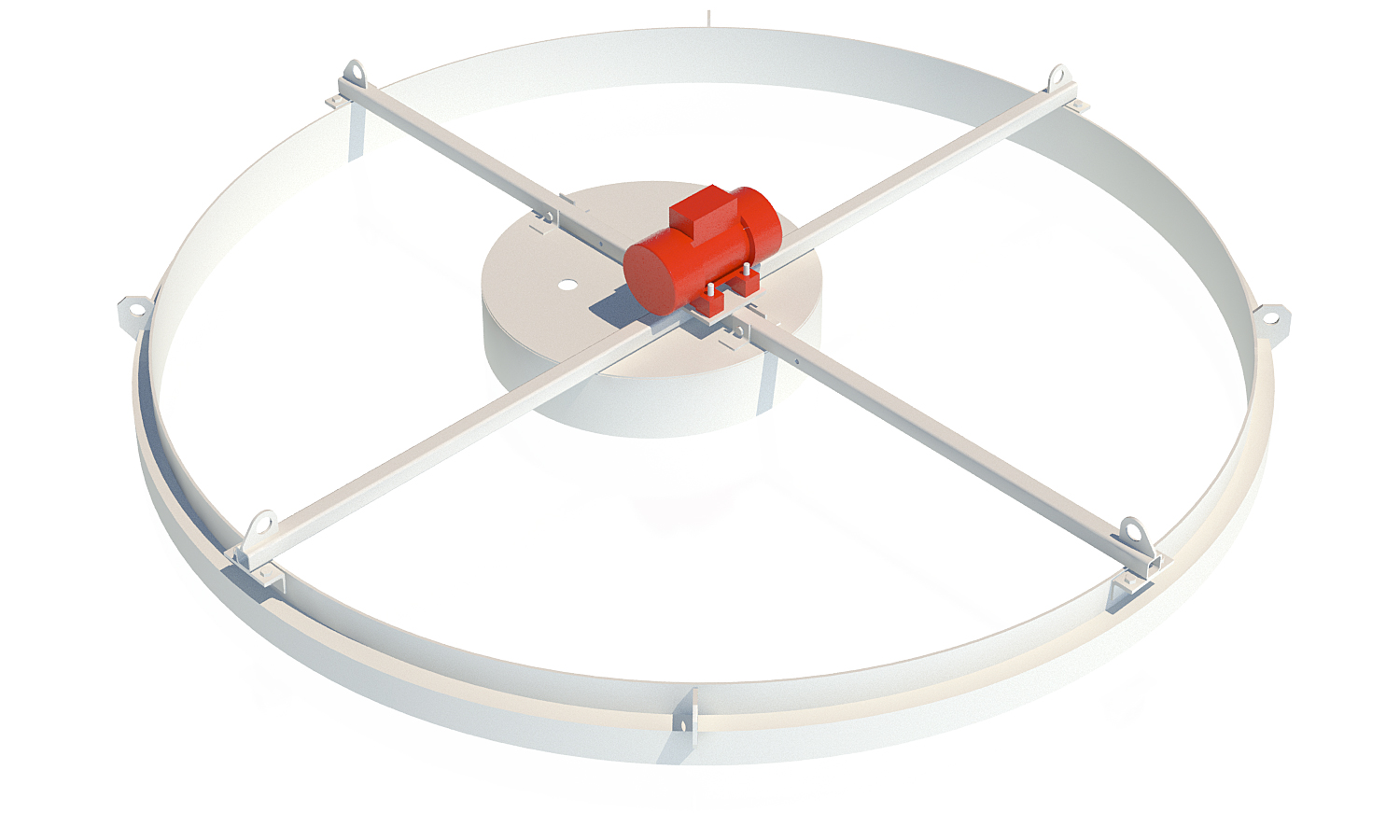

- Maximum fuel viscosity, cSt 6

- Diesel fuel atomization Mechanical

- Power supply, Hz ~3/380V/50 Hz

- Electrical protection degree IP40

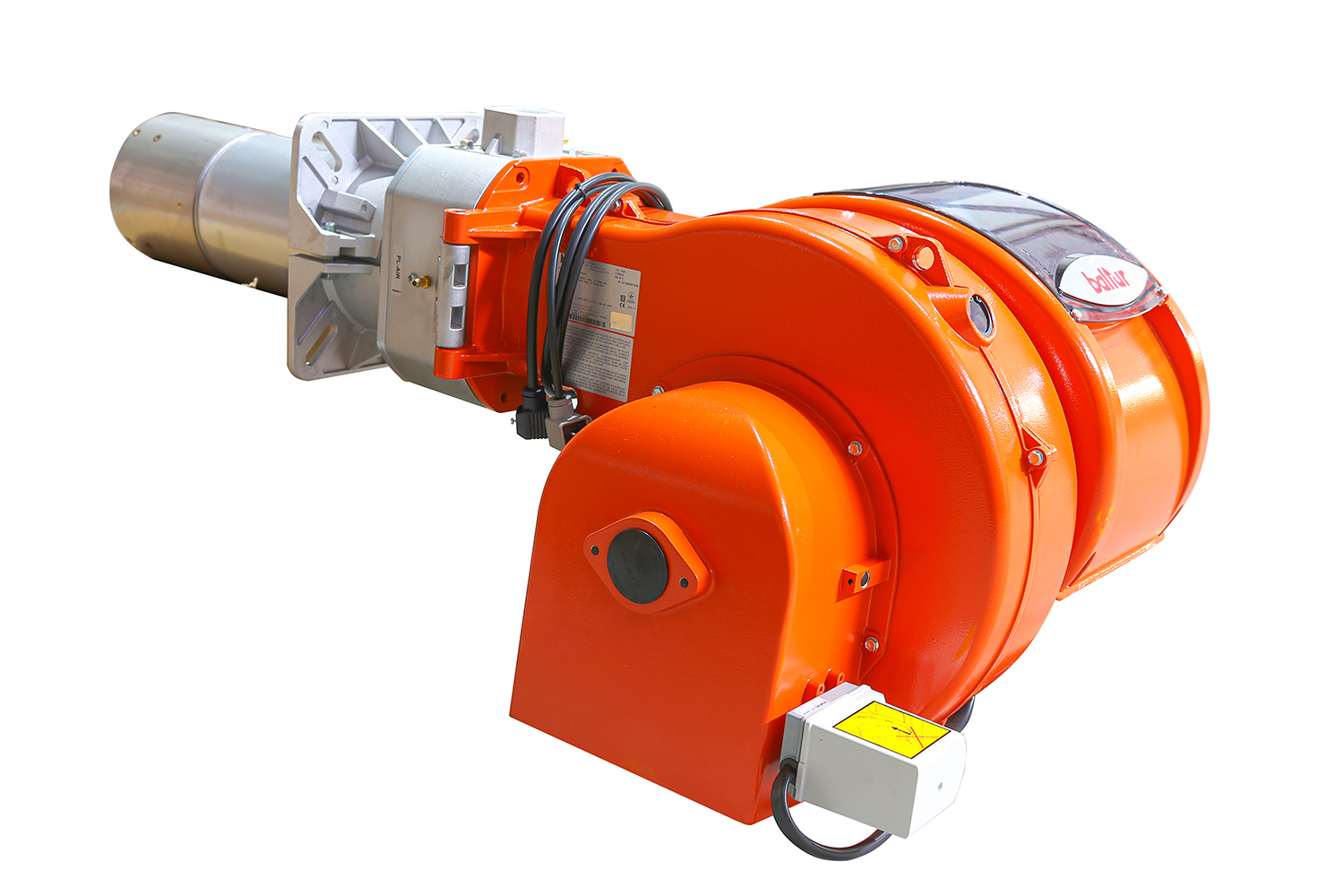

493 400

- power, kWt 240÷1200

- Power regulation Smooth two-stage

- mode Intermittent (stop once every 24 hours)

- Nitrogen oxide emissions 2nd grade

- Noise level, dB(A) 75,5

- Connecting gas fittings from below

- Power supply, Hz ~3/380V/50

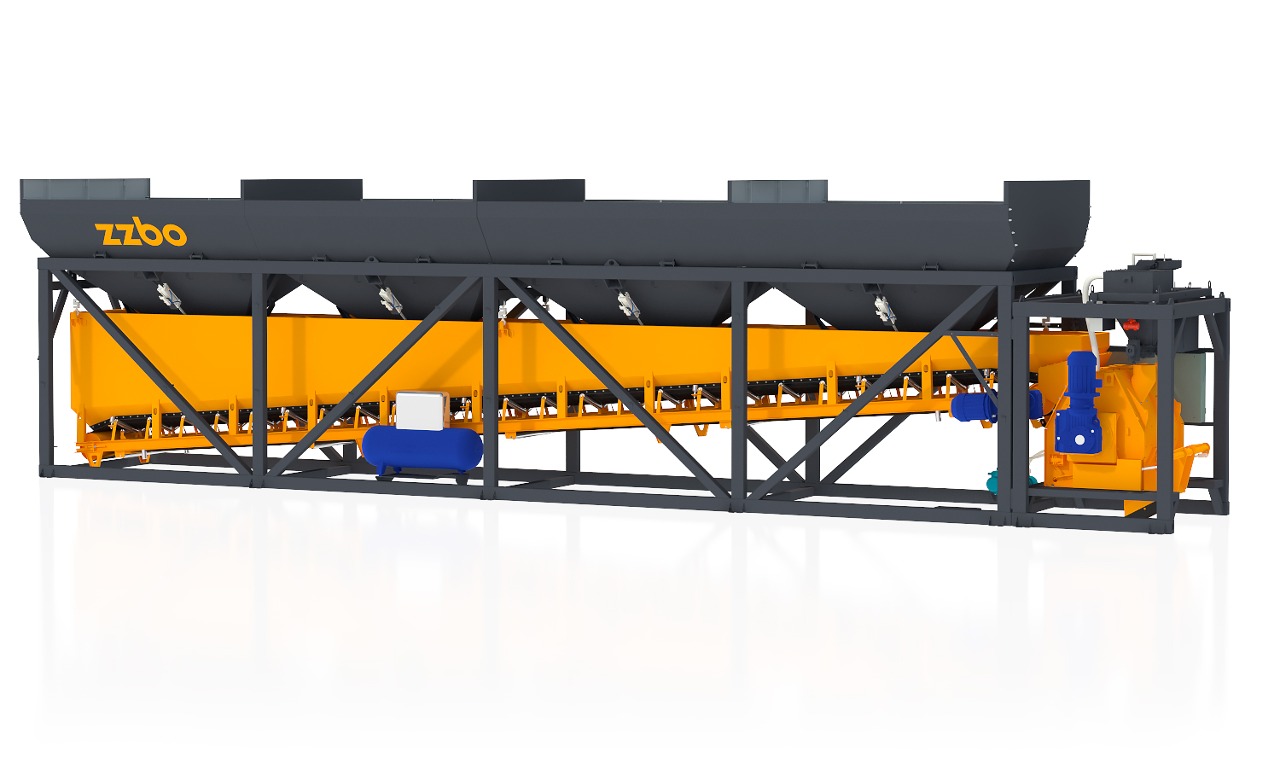

4 133 000

- Capacity, cu m per hour 10...20

- single-shaft mixer BP-1G-500

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (3 х 8) = 24

- Total power, kW 23

- Sector gate, pneumatic control

- Weight, kg 7200

425 800

- power, kWt 400÷1300

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Maximum fuel viscosity, cSt 6

- Diesel fuel atomization Mechanical

- Power supply, Hz ~3/380V/50

- Electrical protection degree IP40

520 000

- power, kWt 300÷1500

- Power regulation Smooth two-stage

- mode Intermittent (stop once every 24 hours)

- Nitrogen oxide emissions 2nd grade

- Noise level, dB(A) 79

- Connecting gas fittings from below

- Power supply, Hz ~3/380V/50

553 400

- power, kWt 300÷1500

- Power regulation Modulation

- Regulation of the gas-air mixture Mechanical

- Modulation depth 1:4

- mode Intermittent (stop once every 24 hours)

- Nitrogen oxide emissions 2nd grade

- Noise level, dB(A) 79

429 200

- power, kWt 500÷1600

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Maximum fuel viscosity, cSt 6

- Diesel fuel atomization Mechanical

- Power supply, Hz ~3/380V/50

- Electrical protection degree IP40

584 900

- power, kWt 400÷2100

- Power regulation smooth two-stage

- mode Intermittent (stop once every 24 hours)

- Nitrogen oxide emissions 2nd grade

- Noise level, dB(A) 85

- Connecting gas fittings from below

- Power supply, Hz ~3/380V/50

544 100

- power, kWt 800÷2100

- Power regulation Two-stage

- mode Intermittent (stop once every 24 hours)

- Maximum fuel viscosity, cSt 6

- Diesel fuel atomization Mechanical

- Power supply, Hz ~3/380V/50

- Electrical protection degree IP40

3 750 000

- Масса, кг (включая тяговое устройство) 2050

- Объем бадьи (полный/рабочий), м 2,05 / 1,5

- Электропитание троллейное

- Скорость передвижения бетоновоза, м/мин 80

- Length, mm 4415

- Width, mm 1,650

- Height, mm 1665

425 000

212 500

425 000

4 489 200

- Capacity, cu m per hour 10...20

- single-shaft mixer БП-1Г-500С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (4 х 8) = 32

- Total power, kW 27

- Sector gate, pneumatic control

- Weight, kg 8630

2 869 900

- Productivity, t / h 100

- Lifting height, m 14

- Number of buckets, pcs 70

- Bucket pitch, mm 400

- Bucket volume, l 8

- Electric motor power, kW 11

- Rotation frequency of the drive shaft, rpm 52

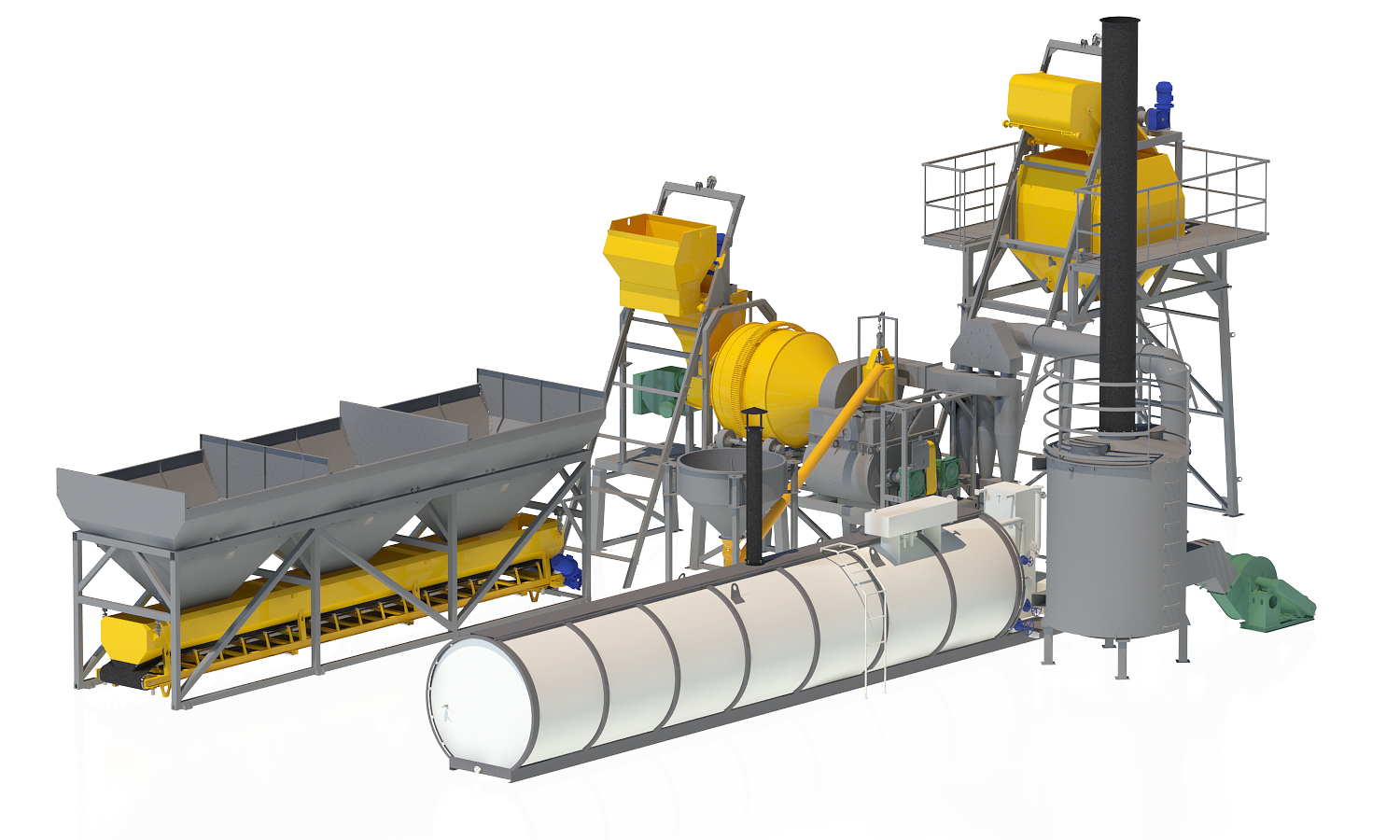

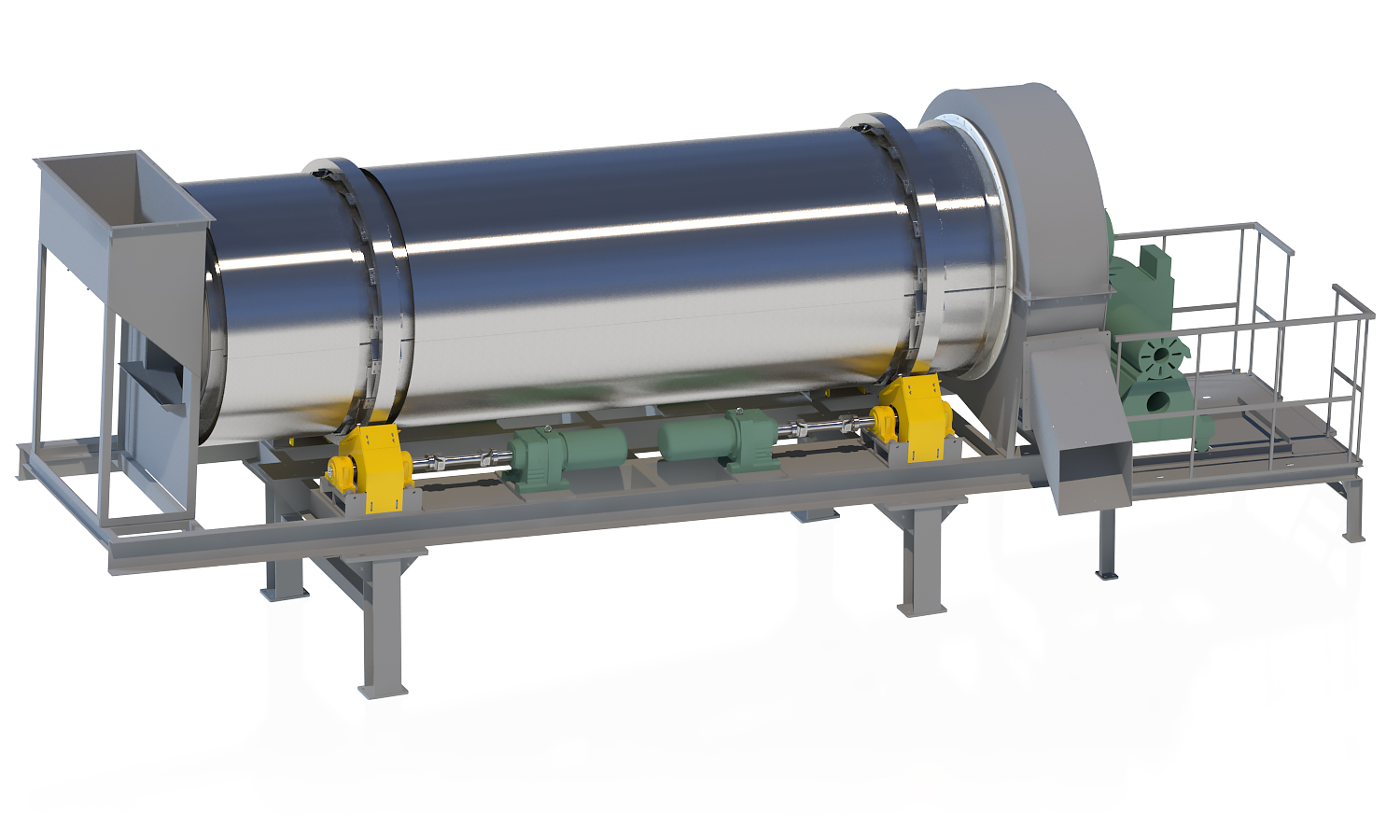

10 921 700

- Productivity, tons hour 20

- The number and volume of bins, the number of x m. Cube 3 x 8

- Weighing range of inert, kg 2,000

- Asphalt-shaft, l 750

- The volume of the hopper ready asphalt, tons 8

- asphalt temperature at the outlet, hail 120...170

- Length, mm 21871

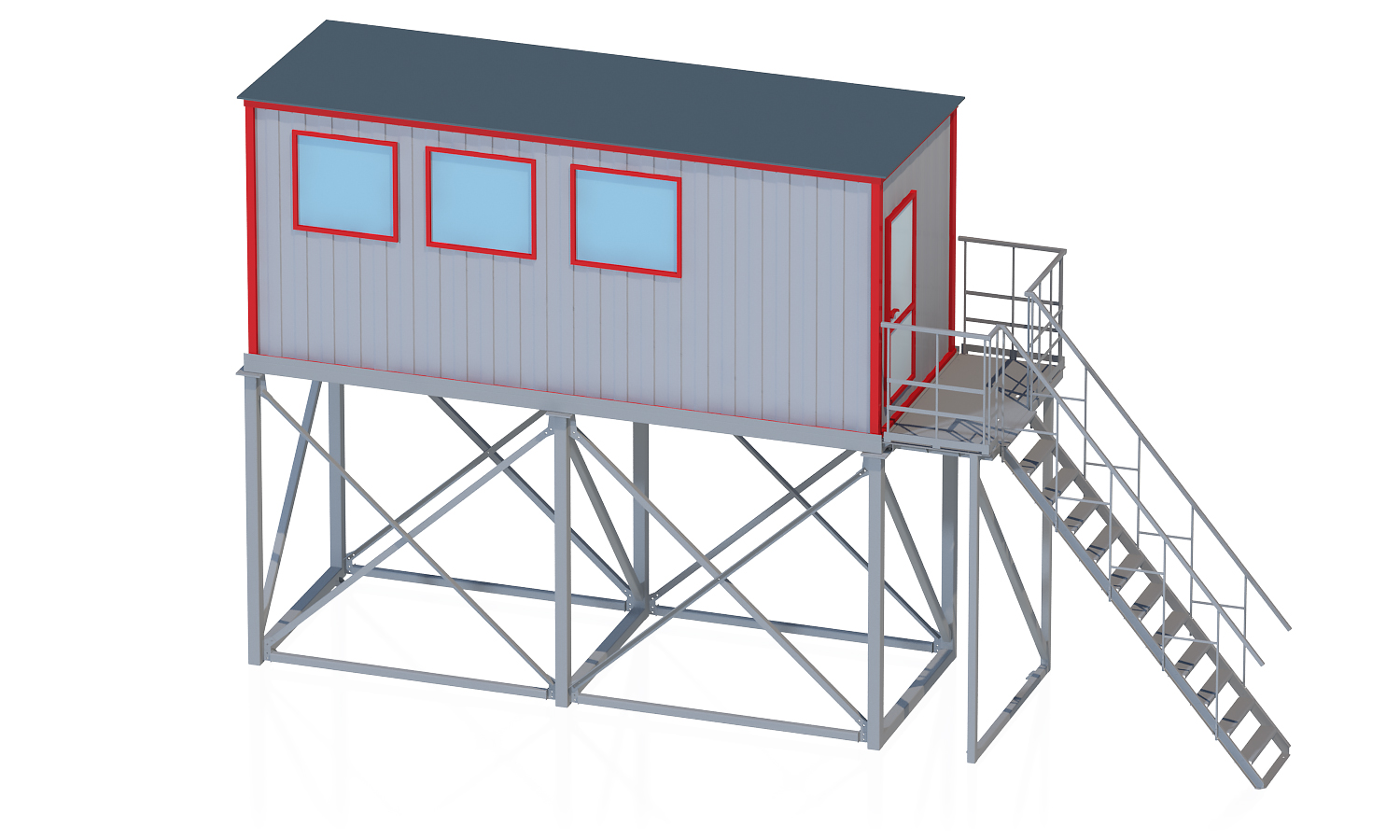

29 235 400

- plant performance 80 t / h (3% moisture material)

- Supply hopper with inert materials, count and volume. 5 bins of 8 m3

- The thermal power of the burner 6500 kW

- Number screening sieves 5

- The volume of hot material hopper 12 m3

- Weight one batch 1,000 kg

- Total electric power plant 230 kW.

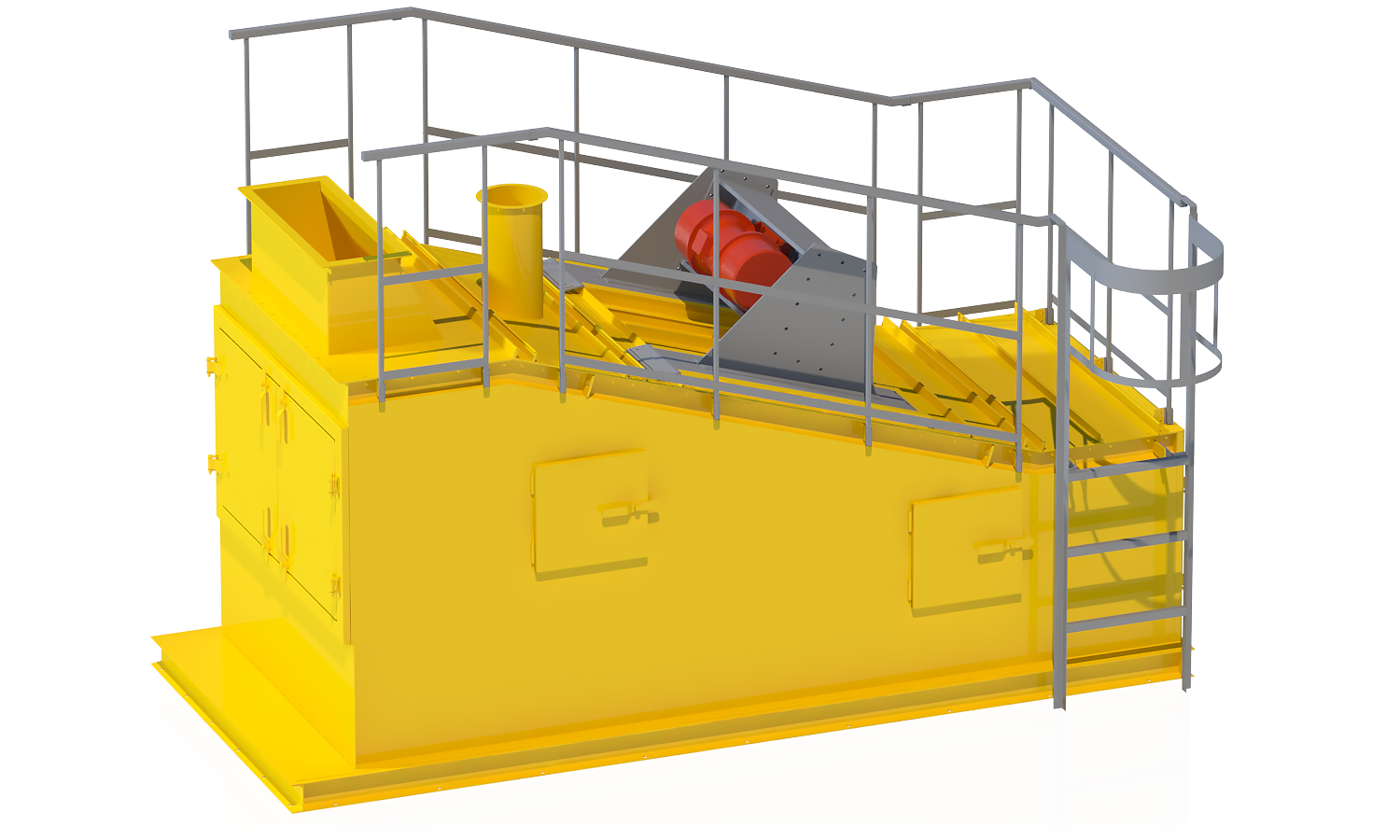

1 690 200

- Filtration plants 1,200

- Filtration plants 3,000

- Filtration plants 14

- Number of tiers of screening surfaces, pcs 5

- Number of tiers of screening surfaces, pcs Number of tiers of screening surfaces, pcs

- Number of tiers of screening surfaces, pcs Number of tiers of screening surfaces, pcs 1,000

- Number of tiers of screening surfaces, pcs 100

1 934 500

- Number of tiers of screening surfaces, pcs3 14

- Number of pneumatic cylinders, pcs. 5

- Number of pneumatic cylinders, pcs.3 7

- Number of pneumatic cylinders, pcs.3 Number of pneumatic cylinders, pcs.

- Number of pneumatic cylinders, pcs.3 1,6

- Number of pneumatic cylinders, pcs.3 1,6

- Number of pneumatic cylinders, pcs.3 2,1

3 858 800

- Number of pneumatic cylinders, pcs. 1,000

- The volume of the batcher of hot inert materials, m3 The volume of the batcher of hot inert materials, m

- The volume of the batcher of hot inert materials, m3 0The volume of the batcher of hot inert materials, m

- The volume of the batcher of hot inert materials, m3 0,35

- The volume of the batcher of hot inert materials, m The volume of the batcher of hot inert materials, m

- Load cells for weighing mineral powder and dust, pcs x kg Load cells for weighing mineral powder and dust, pcs x kg

- The volume of the batcher of hot inert materials, m Load cells for weighing mineral powder and dust, pcs x kg

917 600

- Drive power, kW 7.5

- Load cells for weighing mineral powder and dust, pcs x kg 75

- Load cells for weighing mineral powder and dust, pcs x kg 1,5

- Load cells for weighing mineral powder and dust, pcs x kg 600

- Load cells for weighing mineral powder and dust, pcs x kg O Load cells for weighing mineral powder and dust, pcs x kg

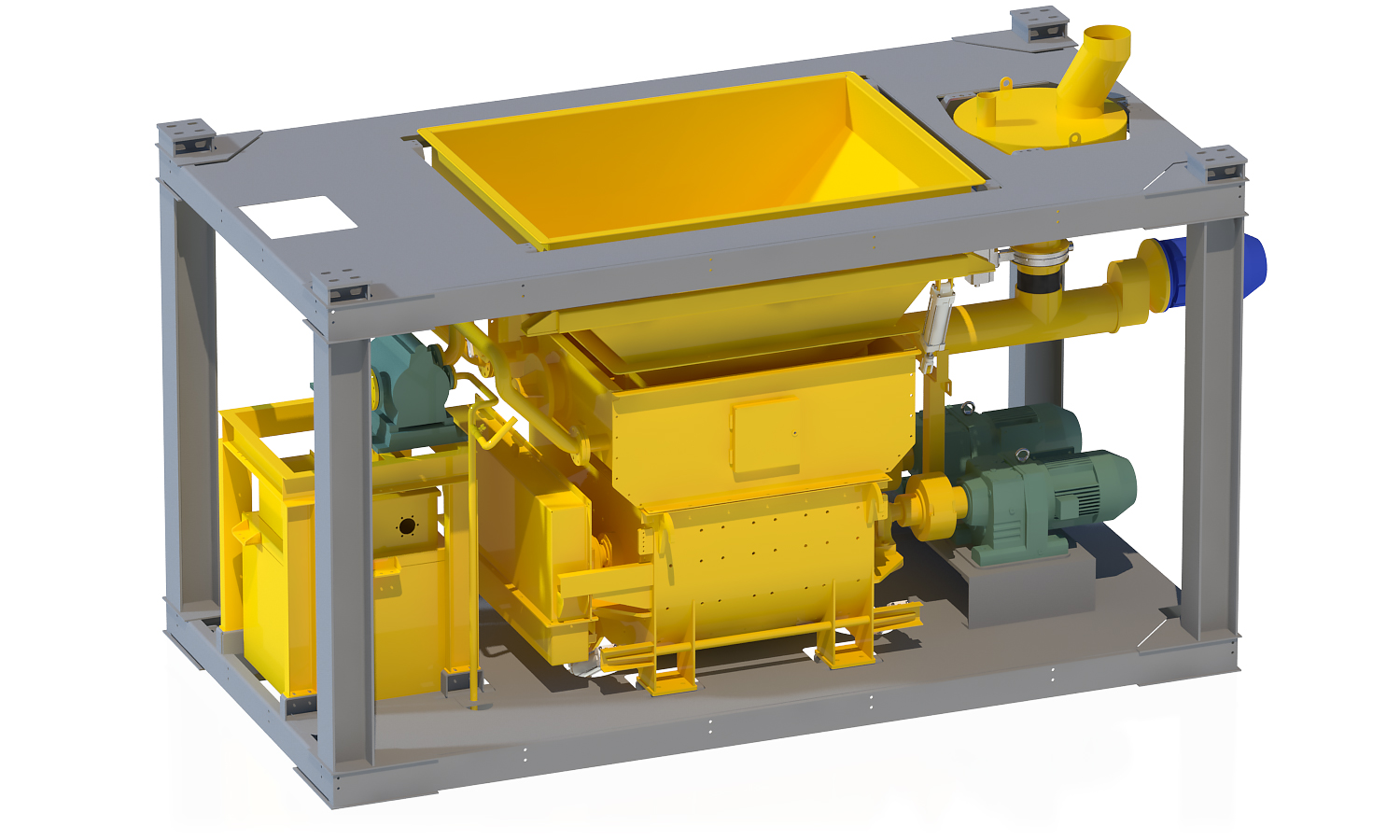

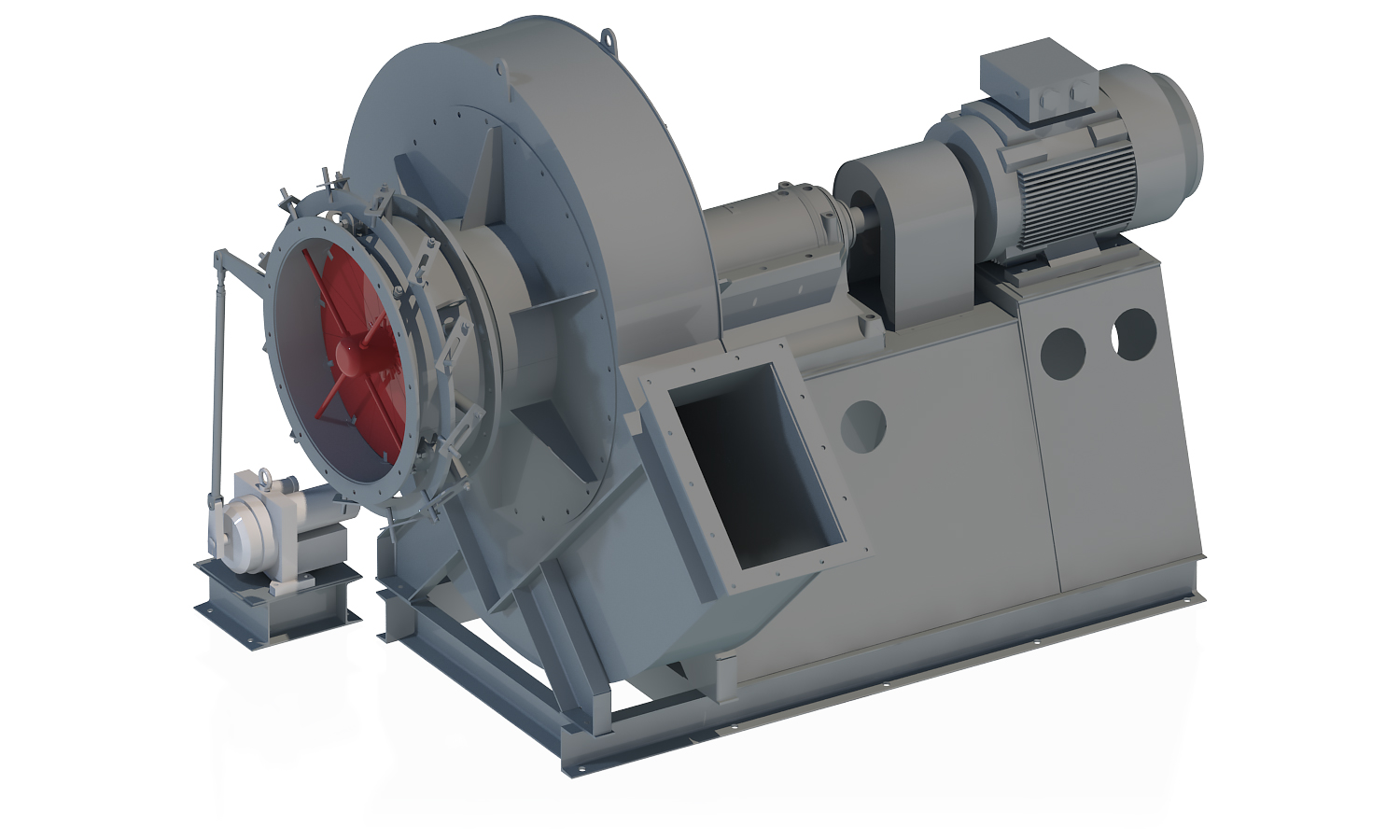

4 161 800

- End product capacity, t/h 80

- End product capacity, t/h 3

- End product capacity, t/h 7.5

- End product capacity, t/h 4

- Load cells for weighing mineral powder and dust, pcs x kg 11

- End product capacity, t/h End product capacity, t/h

- Operating thermal power of the burner, MW Operating thermal power of the burner, MW

644 300

- Operating thermal power of the burner, MW3 8

- Operating thermal power of the burner, MW 2,2

- Operating thermal power of the burner, MW Operating thermal power of the burner, MW

- Operating thermal power of the burner, MW 500

- Vibrator power, kW 0Vibrator power, kW

3 961 800

- Capacity, cu m per hour 10...20

- single-shaft mixer БП-1Г-500С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (2 х 8) = 16

- Total power, kW 23

- Sector gate, pneumatic control

- Length, mm 10100

850 000

- Length, mm Maximum productivity of the belt feeder, t/h

- Width, mm Maximum productivity of the belt feeder, t/h

- Height, mm Maximum productivity of the belt feeder, t/h

- Weight, t 2,7

1 182 400

- Maximum productivity of the belt feeder, t/h Maximum productivity of the belt feeder, t/h

- A type Maximum productivity of the belt feeder, t/h

- Construction type Construction type

- Construction type 85

- Construction type3 1,500

- Construction type O from “Bulgaria" 200

- Productivity (at a flow rate in the cylindrical part of 2.5 m/s), mOProductivity (at a flow rate in the cylindrical part of 2.5 m/s), m Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m

1 289 000

- A type Скруббер "Вентури"

- Construction type 96

- Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m

- Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m 30

- Supply Pump Parameters:

- Supply Pump Parameters: 4

- Supply Pump Parameters:3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Supply Pump Parameters:

4 766 300

- Filtration area, m² 430

- Supply Pump Parameters:3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Supply Pump Parameters:

- Supply Pump Parameters: 384

- Filter cloth material for sleeves Filter cloth material for sleeves

- Filter cloth material for sleeves O from “Bulgaria" Filter cloth material for sleeves

- Filter cloth material for sleeves O from “Bulgaria" Filter cloth material for sleeves

- Количество механизмов очистки, шт 3

462 000

- Filter cloth material for sleeves3 1,57

- Dispenser volume, dm3 23

- Dispenser volume, dm3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Dispenser volume, dm

- Dispenser volume, dm 90

- Dispenser volume, dm Dispenser volume, dm

- Dispenser volume, dm Dispenser volume, dm

- Dispenser volume, dm Dispenser volume, dm

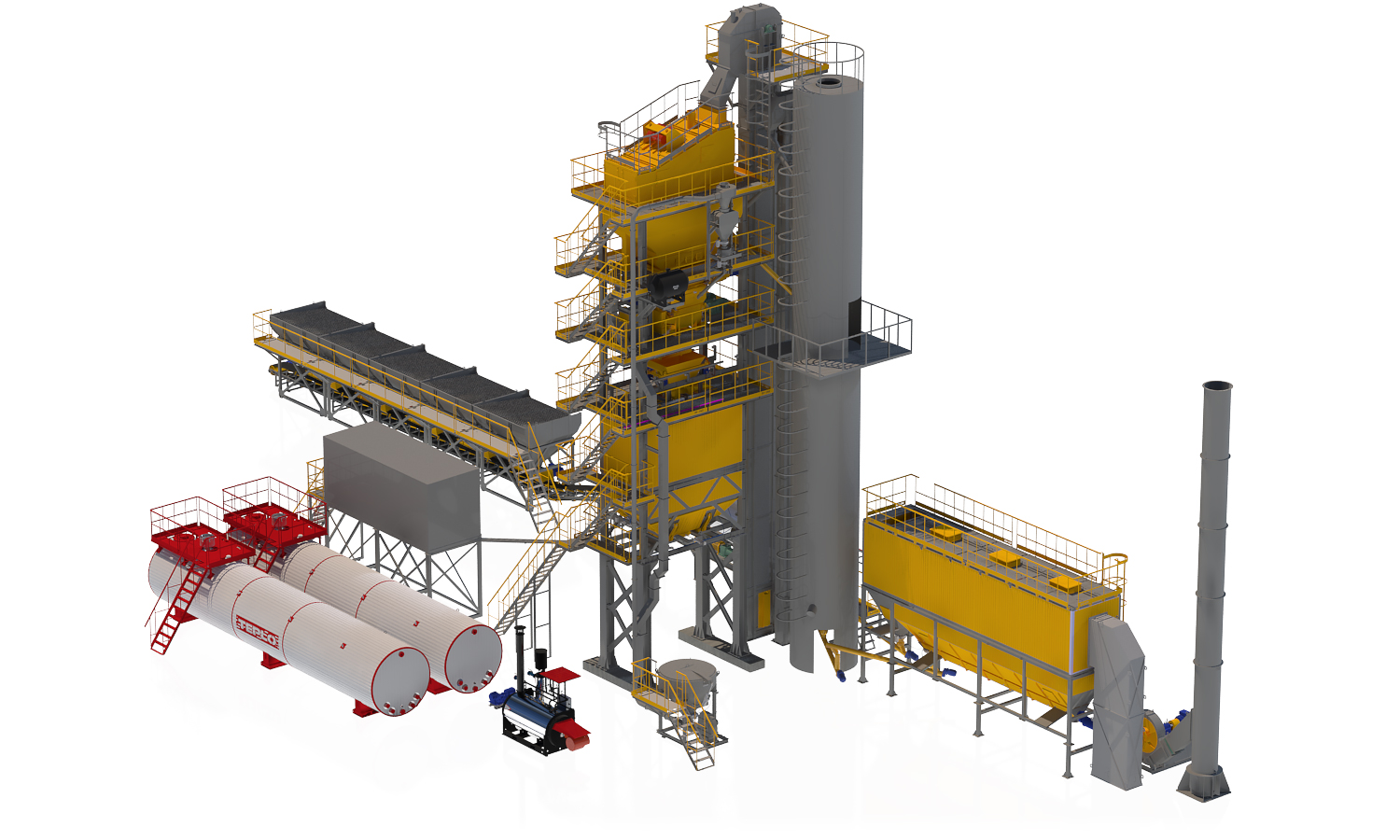

68 980 000

- Plant productivity, t/h 160 (3% moisture content of materials)

- Feed hoppers with inert materials, quantity, volume 6 bunkers of 10m³

- Thermal power of the burner, MW 14

- Number of screen sieves, pcs 6

- Hot materials hopper volume, m³ 22

- Weight of one batch, kg 2,000

- Dryer drum drive power, m² 4 x 11

913 900

- Productivity, m3Productivity (at a flow rate in the cylindrical part of 2.5 m/s), m Productivity, m

- Productivity, m Productivity, m

- Drive power, kW 55

- Productivity, m 1450

- Productivity, m 16

880 500

- Productivity, m 2

- Productivity, m 2

- Oil registers, quantity, pcs 2

- Productivity, m Side, top

- Side, top

- Side, top2 26

- Side, top2 11

1 144 200

- Productivity, m 1

- Reject hopper capacity (at a density of 1.8 t/m³), m³ (t) 0,1

- Installed power, kW 120

- 23 866 $ Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

- Reject hopper capacity (at a density of 1.8 t/m³), m³ (t) Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

- Maximum oil heating temperature, °C 23 866 $

-

Объем теплоносителя м3

4 969 300

- Side, top Side, top

- Side, top Side, top

- Skip capacity (at a density of 1.8 t/m³), m³ (t) 0Skip capacity (at a density of 1.8 t/m³), m³ (t)

- Skip capacity (at a density of 1.8 t/m³), m³ (t) Skip capacity (at a density of 1.8 t/m³), m³ (t)

- Skip capacity (at a density of 1.8 t/m³), m³ (t) 1,3

- Skip capacity (at a density of 1.8 t/m³), m³ (t) 2

- Reject hopper capacity (at a density of 1.8 t/m³), m³ (t) Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

4 394 200

- Capacity, cu m per hour 10...20

- single-shaft mixer БП-1Г-500С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (3 х 8) = 24

- Total power, kW 23

- Sector gate, pneumatic control

- Length, mm 13,000

4 735 300

- Количество секций, шт 3

- Общая вместимость (при плотности 1,8 т/м³), м³ (т) 28 (50)

- Вместимость секций готовой смеси (при плотности 1,8 т/м³), м³ (т) по 12 (21,5)

- Вместимость секции брака (при плотности 1,8 т/м³), м³ (т) 4 (7)

3 333 400

- Теплопроизводительность котла, ГКал/ч; 00.3

- Производительность битумного насоса, куб м; 15,7

- Максимальная температура масла, °С +300/+250

- Температура эксплуатации +5...+40 °С

- Полезный объем битумного хранилища, куб. м 28

- Объем теплоносителя в установке, куб. м 0,7

- Thermal insulation URSA basalt, mm 50

1 080 800

- Nominal volume of the container, m3 31

- Working volume of the tank, m3 30

- Oil registers, quantity, pcs 2

- Coolant volume in registers, l 250

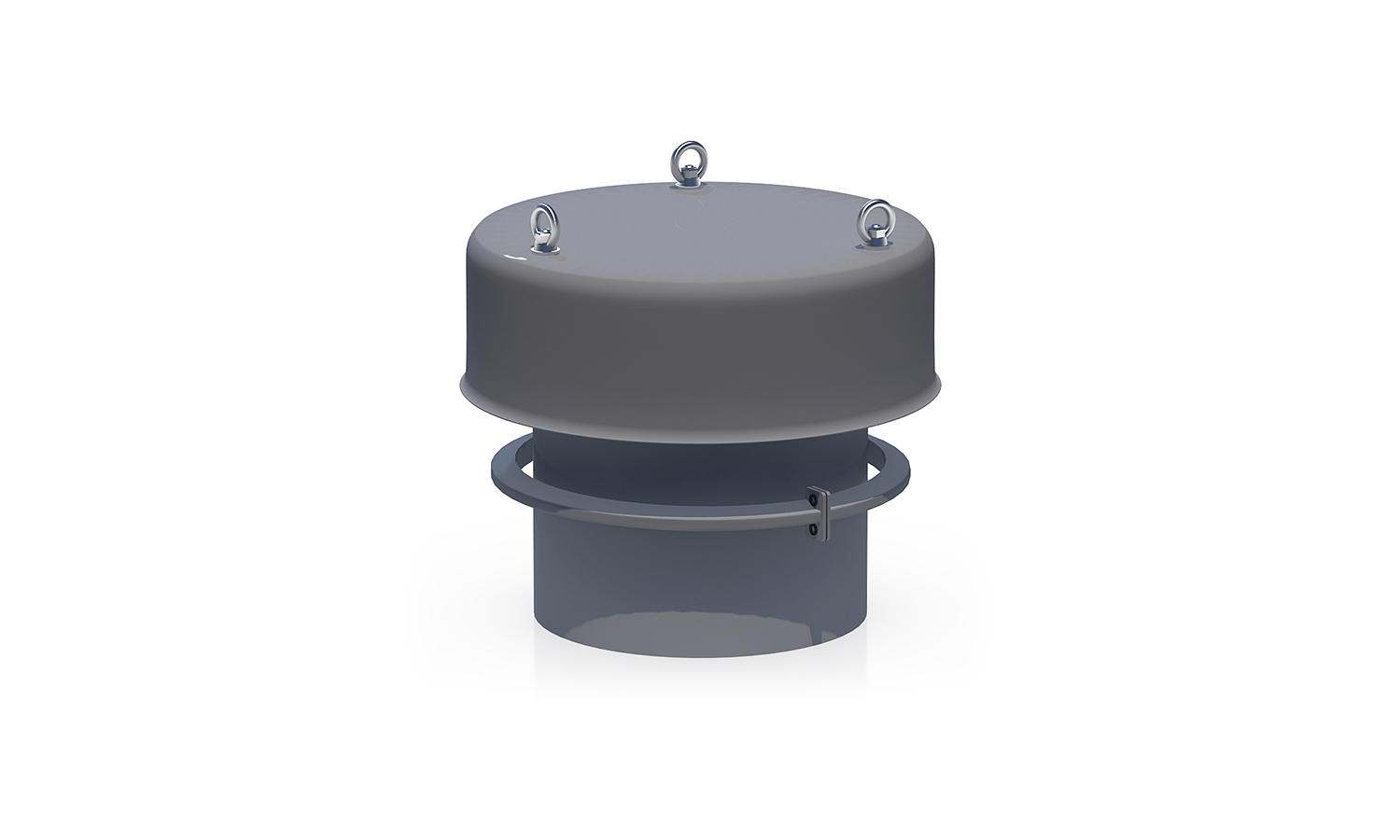

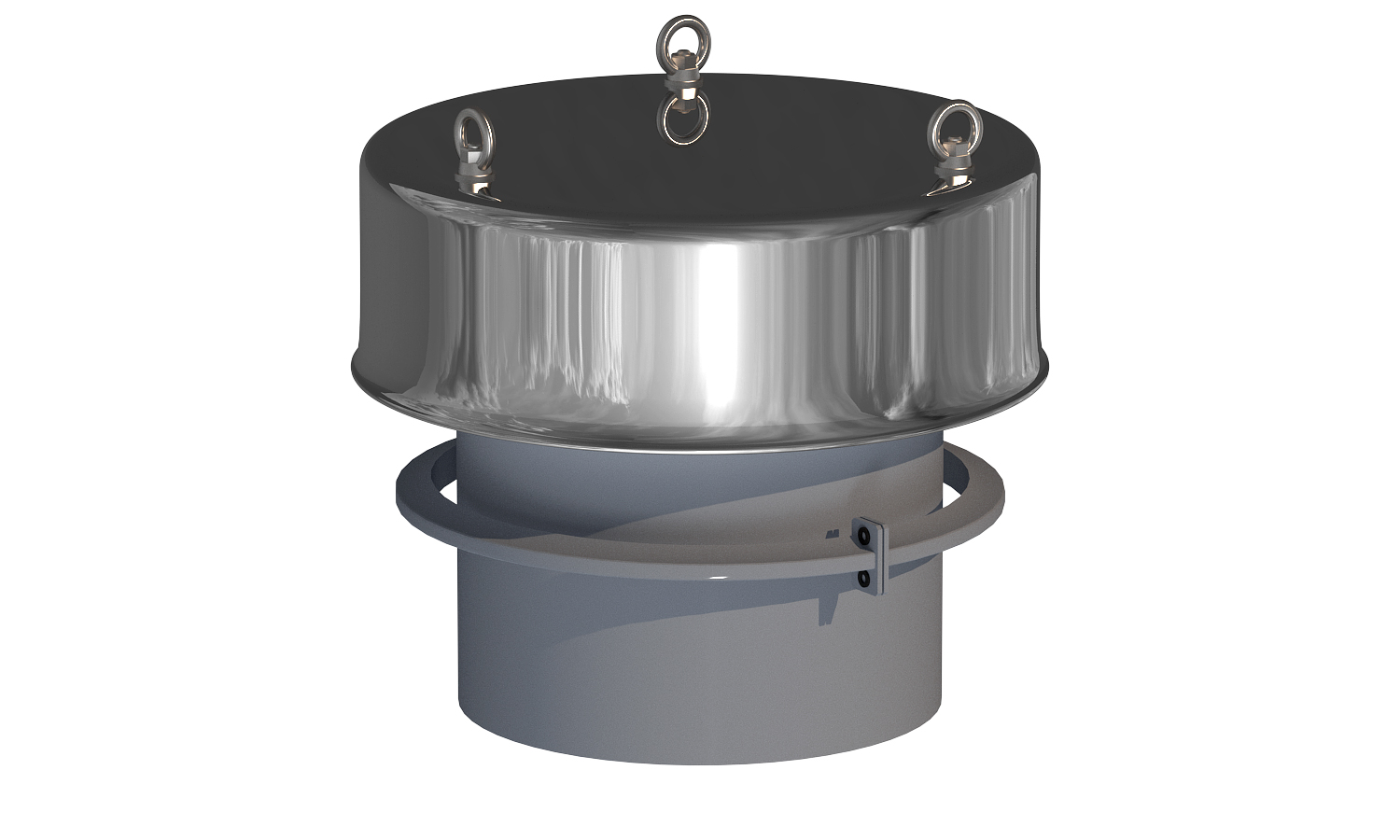

- Ventilation system hatch ⌀600 mm and round deflector DN = 250 mm

- Thermal insulation URSA basalt, mm Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

- housing material steel St.09G2S sheet, s=4 mm of the shell, s=6 mm of the bottom

1 846 200

- Nominal volume of the container, m3 50

- Working volume of the tank, m3 48

- Heating area, m2 30

- Oil registers, quantity, pcs 2

- Coolant volume in registers, l 350

- Ventilation system hatch ⌀600 mm and round deflector DN = 250 mm

- Thermal insulation URSA basalt, mm Reject hopper capacity (at a density of 1.8 t/m³), m³ (t)

176 375

- Splitting force, tons until 10

- The size of the working zone, mm 410 x 570

- Pegs height, mm 280

- Hydraulic pressure, MPa 9...16

- Total installed power, kW 2,2

- Supply voltage, V/Hz 380/50

- Weight, kg 325

303 000

- Splitting force, tons 20

- The size of the working zone, mm 410 x 570

- Pegs height, mm 280

- Hydraulic pressure, MPa 9...21

- Total installed power, kW 5.5

- Supply voltage, V/Hz 380/50

- Weight, kg 505

539 600

- Splitting force, tons 60

- The size of the working zone, mm 820 x 570

- Pegs height, mm 500

- Hydraulic pressure, MPa 9...21

- Total installed power, kW 7.5

- Supply voltage, V/Hz 380/50

- Weight, kg 950

635 300

- Splitting force, tons 80

- The size of the working zone, mm 820 x 570

- Pegs height, mm 500

- Hydraulic pressure, MPa 9...21

- Total installed power, kW 7.5

- Supply voltage, V/Hz 380/50

- Weight, kg 1,000

797 200

- Splitting force, tons 80

- The size of the working zone, mm 1230 x 570

- Pegs height, mm 500

- Hydraulic pressure, MPa 9...21

- Total installed power, kW 7.5

- Supply voltage, V/Hz 380/50

- Weight, kg 1190

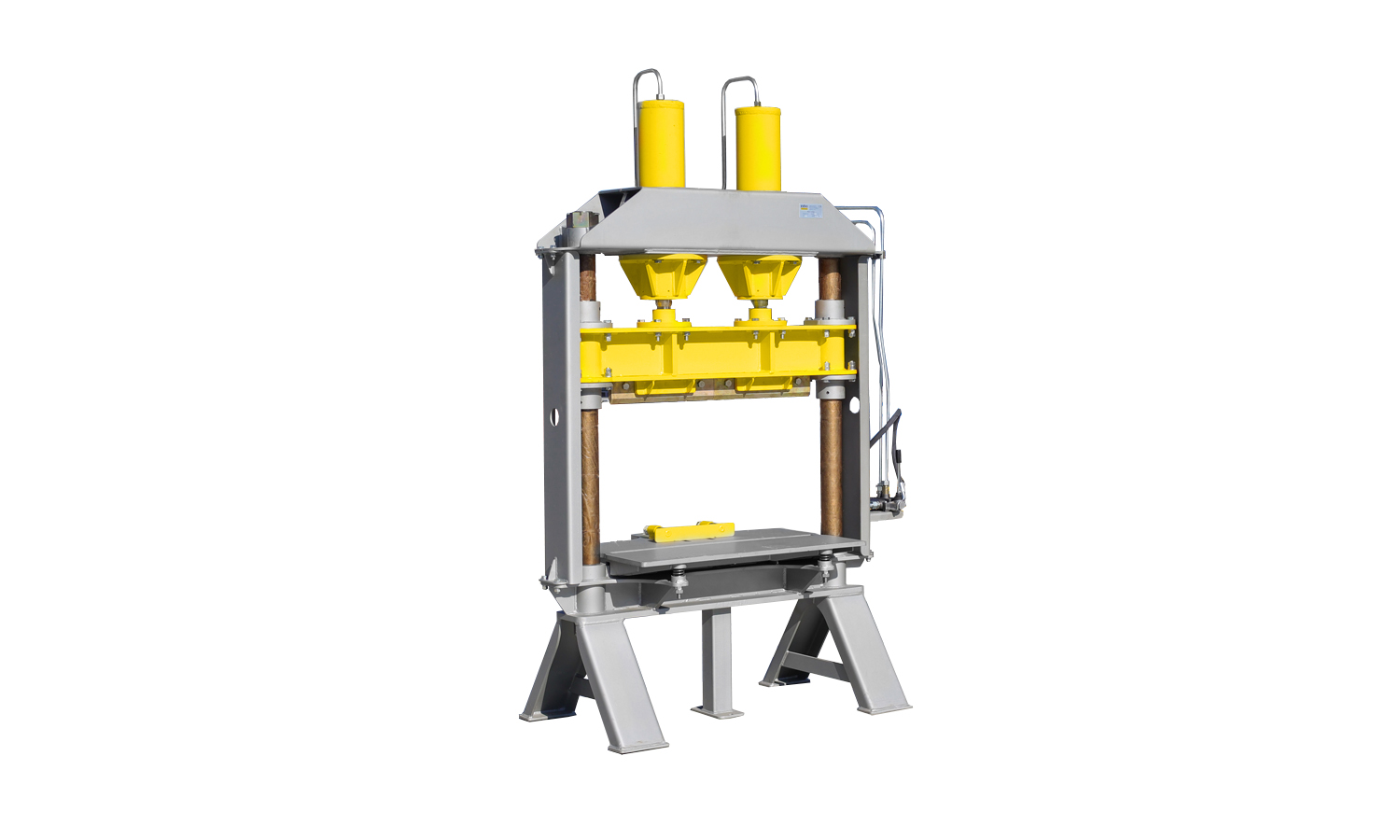

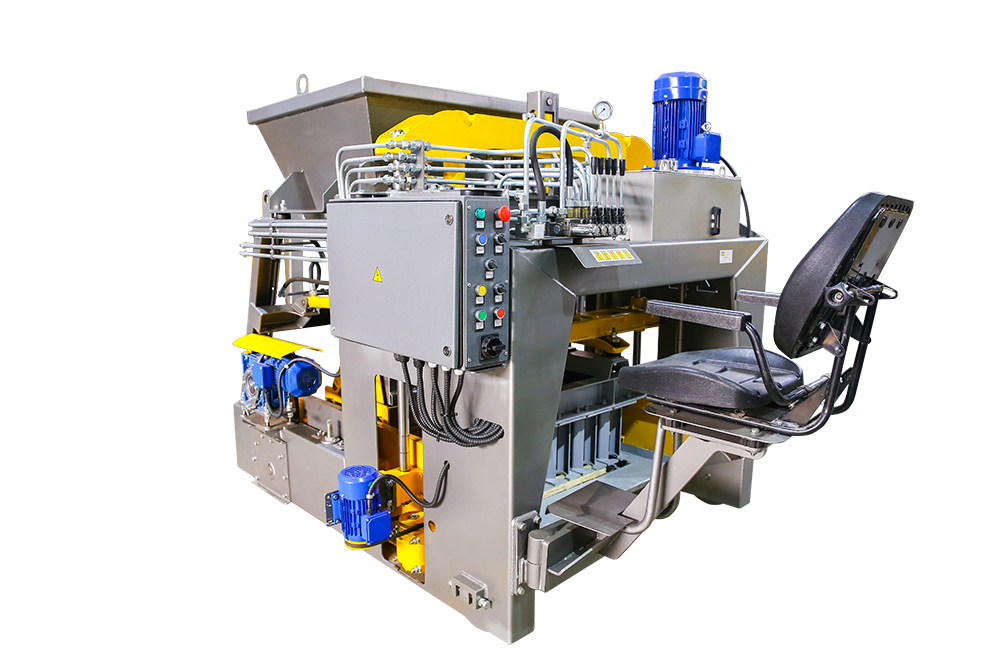

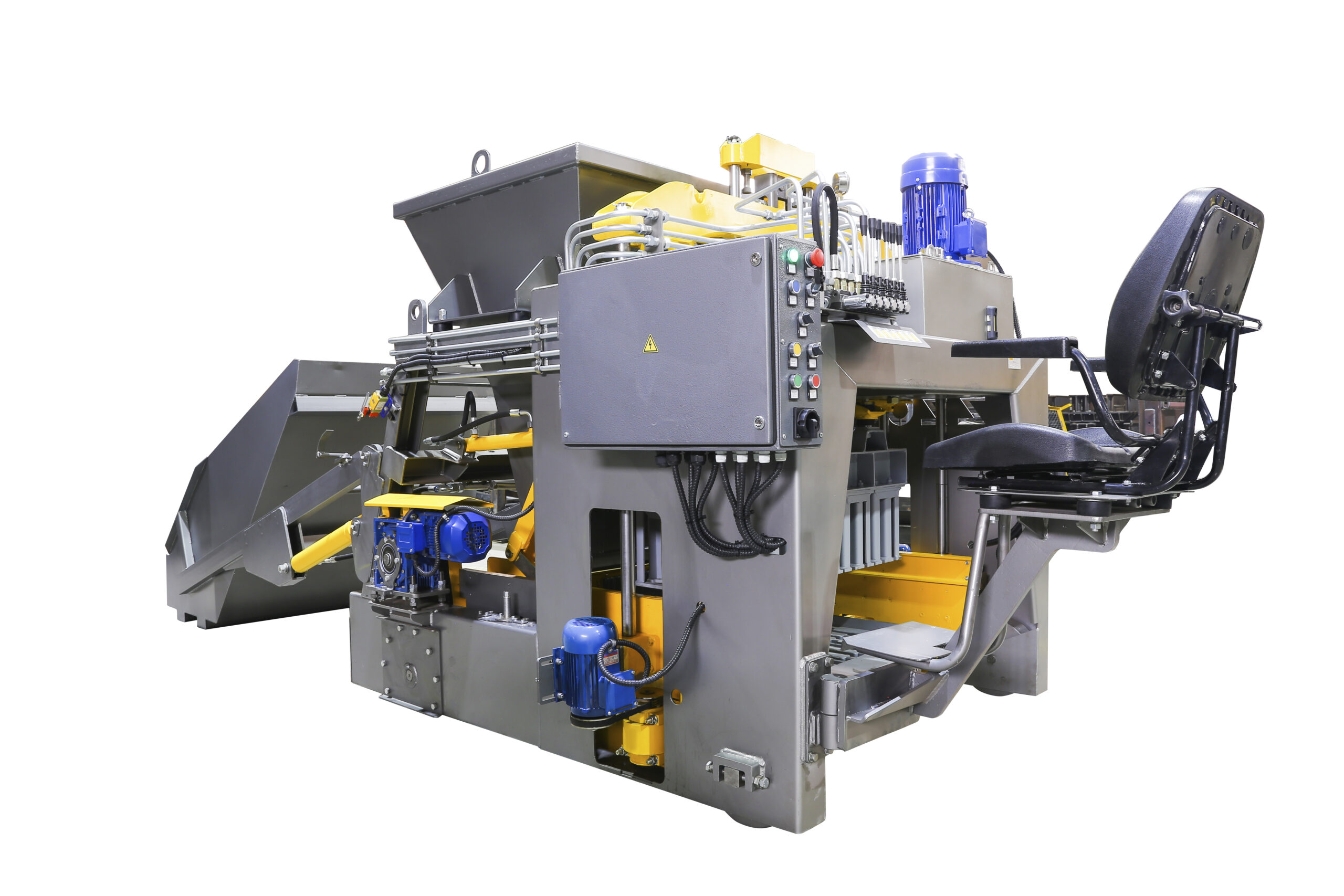

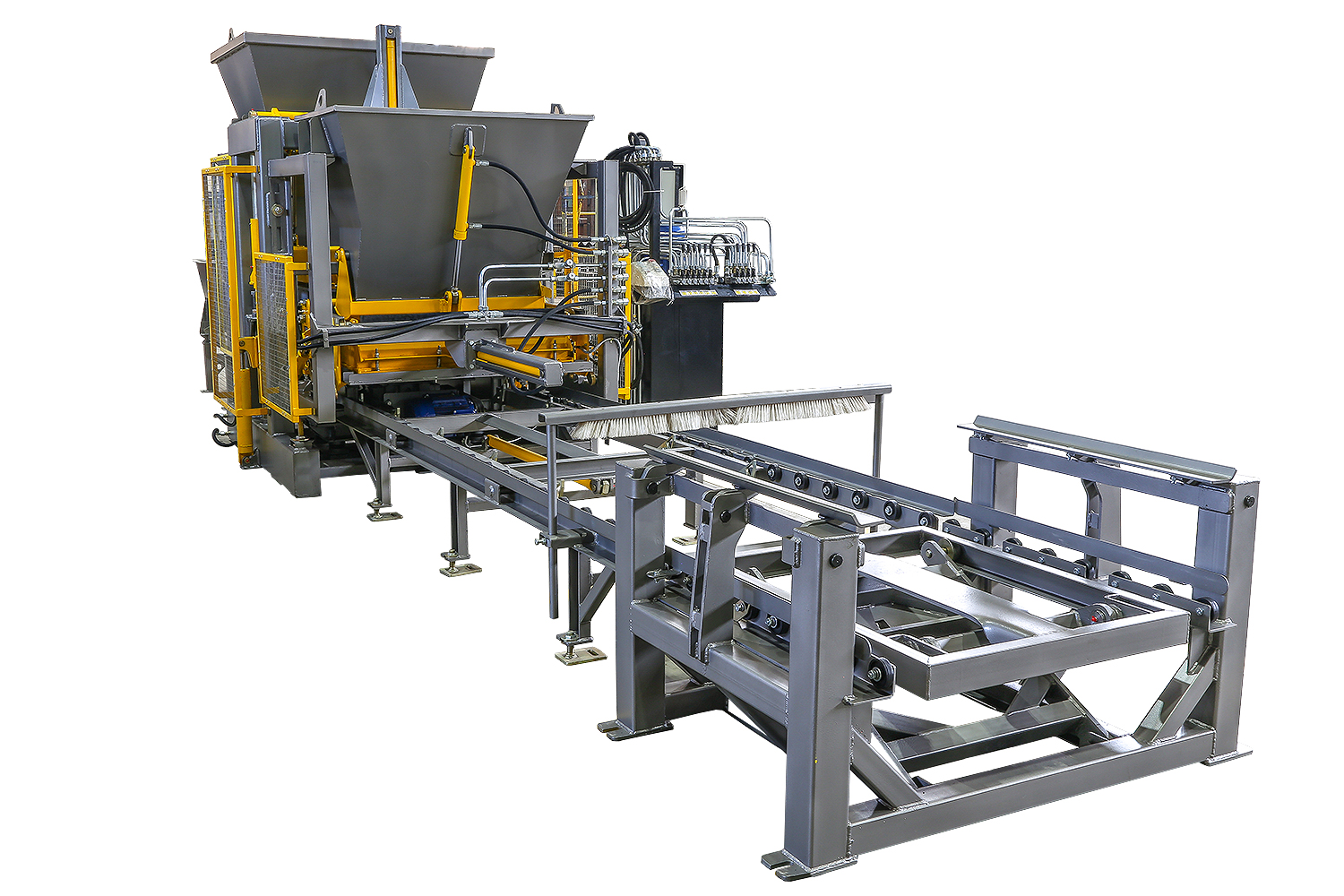

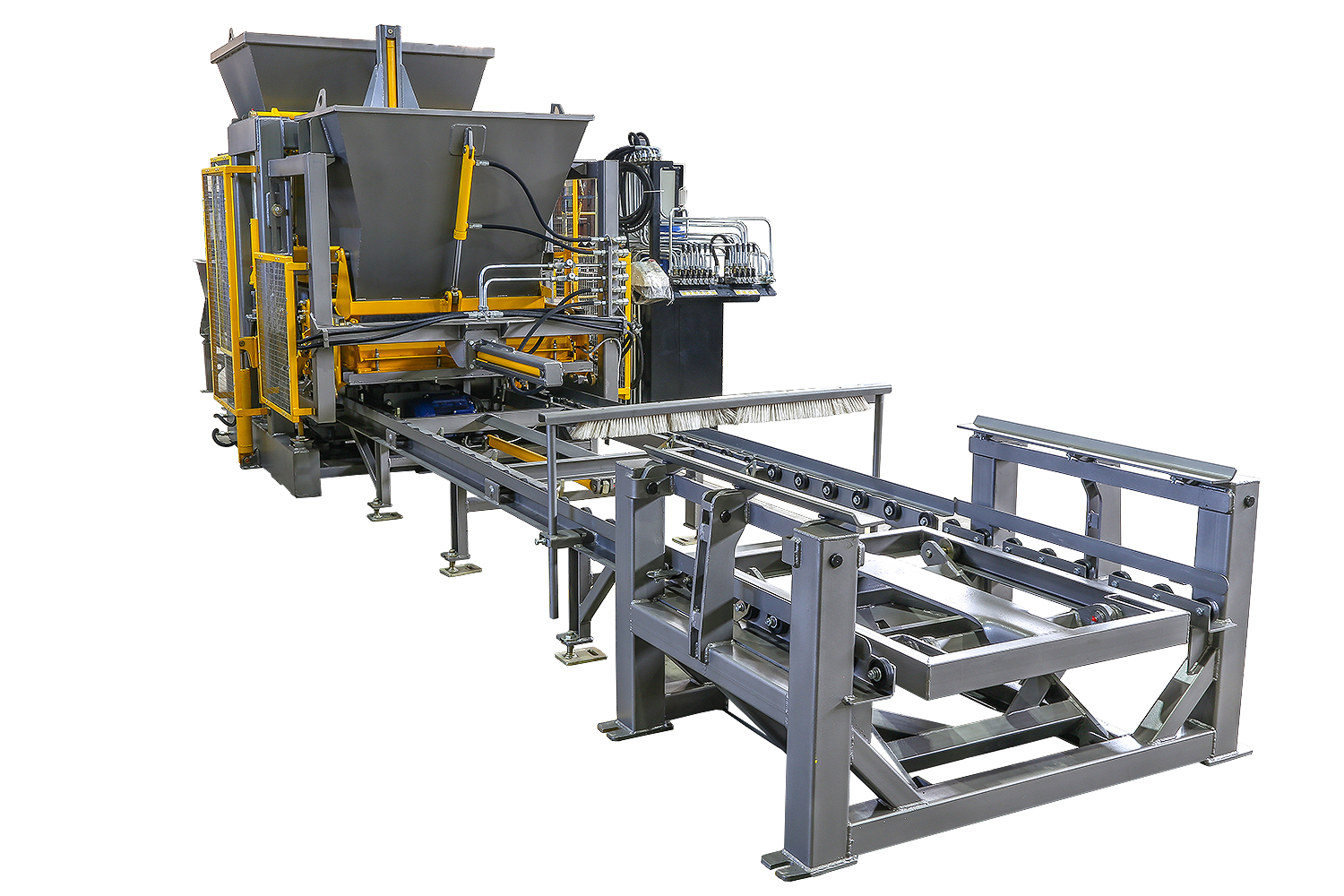

622 000

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 120...225

- Performance on a pavement slab 100h200, pieces per hour 400...750

- molding cycle s 50...90

- The number of moldings per hour piece. 40…75

- Power vibration table, kW 5.5

4 750 400

- Capacity, cu m per hour 10...20

- single-shaft mixer БП-1Г-500С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (4 х 8) = 32

- Total power, kW 27

- Sector gate, pneumatic control

- Length, mm 16,000

154 500

- Length, mm 2552

- Height, mm 580

- Weight, kg 570

86 000

- Length, mm 2,600

- Width, mm 570

- Height, mm 665

- Weight, kg 328

- Thickness 8

89 100

- Length, mm 2,600

- Width, mm 670

- Height, mm 665

- Weight, kg 342

- Thickness 8

93 300

- Length, mm 2,600

- Width, mm 770

- Height, mm 665

- Weight, kg 356

- Thickness 8

96 800

- Length, mm 2,600

- Width, mm 870

- Height, mm 665

- Weight, kg 371

- Metal Thickness 8

4 004 700

- Capacity, cu m per hour 10...20

- single-shaft mixer BP-1G-500s

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (2 х 8) = 16

- Total power, kW 23

- Sector gate, pneumatic control

- Height, mm 10400

89 400

- Length, mm 3138

- Width, mm 611

- Height, mm 485

- Weight, kg 335

- Wall thickness, mm 4

93 000

- Diameter, mm 840

- Height, mm 1145

- Weight, kg 308

- Thickness 6

67 100

- Diameter, mm 972

- Height, mm 1068

- Weight, kg 235

- Thickness 4

125 700

- Diameter, mm 1160

- Height, mm 1290

- Weight, kg 439

- Thickness 6

93 800

- Diameter, mm 1293

- Height, mm 1125

- Weight, kg 335

- Thickness 4

1 200 300

- Size of products KS7, KS10, KS13, COP15, KS20

- The disturbing force, kN 40

- Power vibration table, kW 4

- different frequency vibration option

- Installed power, kW 8,4

- the molding cycle time, s 60..180

- The number of moldings per hour, pieces 7...15

2 374 100

- Size of products KS7, KS10, KS13, COP15, KS20

- The disturbing force, kN 40

- Power vibration table, kW 4

- different frequency vibration option

- Installed power, kW 8,4

- the molding cycle time, s 60...180

- The number of moldings per hour, pieces 10...15

189 200

- Diameter, mm 1680

- Height, mm 1344

- Weight, kg 650

- Metal Thickness 6

4 437 100

- Capacity, cu m per hour 10...20

- single-shaft mixer БП-1Г-500С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (3 х 8) = 24

- Total power, kW 23

- Sector gate, pneumatic control

- Length, mm 13300

144 200

- Diameter, mm 1814

- Height, mm 1183

- Weight, kg 515

- Metal Thickness 4

253 200

- Diameter, mm 2,200

- Height, mm 1350

- Weight, kg 882

- Metal Thickness 6

196 500

- Diameter, mm 2334

- Height, mm 1239

- Weight, kg 700

- Metal Thickness 4

25 100

- Diameter, mm 1160

- Height, mm 150

- Weight, kg 92

32 000

- Diameter, mm 1680

- Height, mm 150

- Weight, kg 118

2 546 800

- Size of products KS7, KS10, KS13, COP15, KS20

- The disturbing force, kN 64

- Power vibration table, kW 6,4

- different frequency vibration option

- Installed power, kW 11,9

- the molding cycle time, s 60...180

- The number of moldings per hour, pieces 7...15

38 900

- Diameter, mm 2,200

- Height, mm 150

- Weight, kg 144

789 800

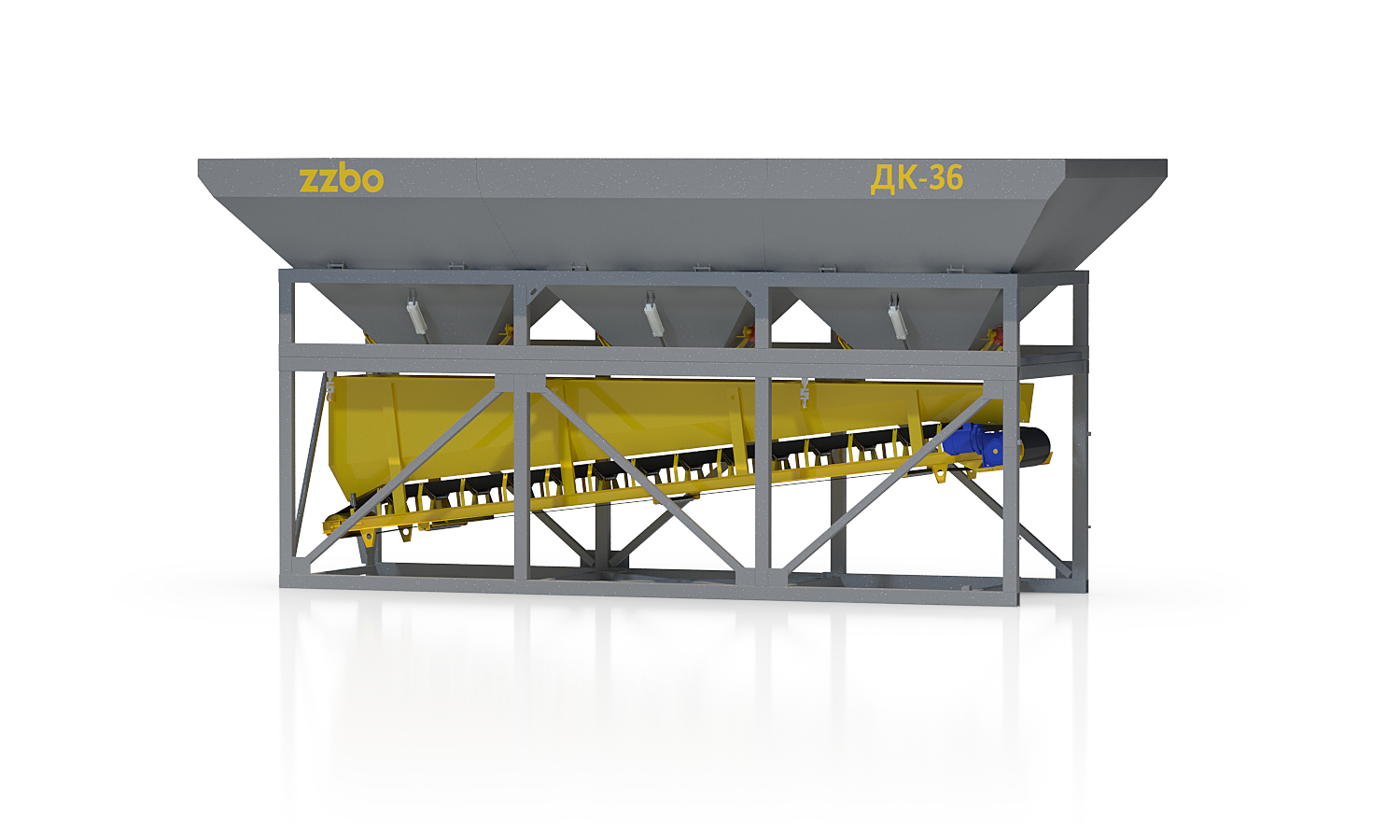

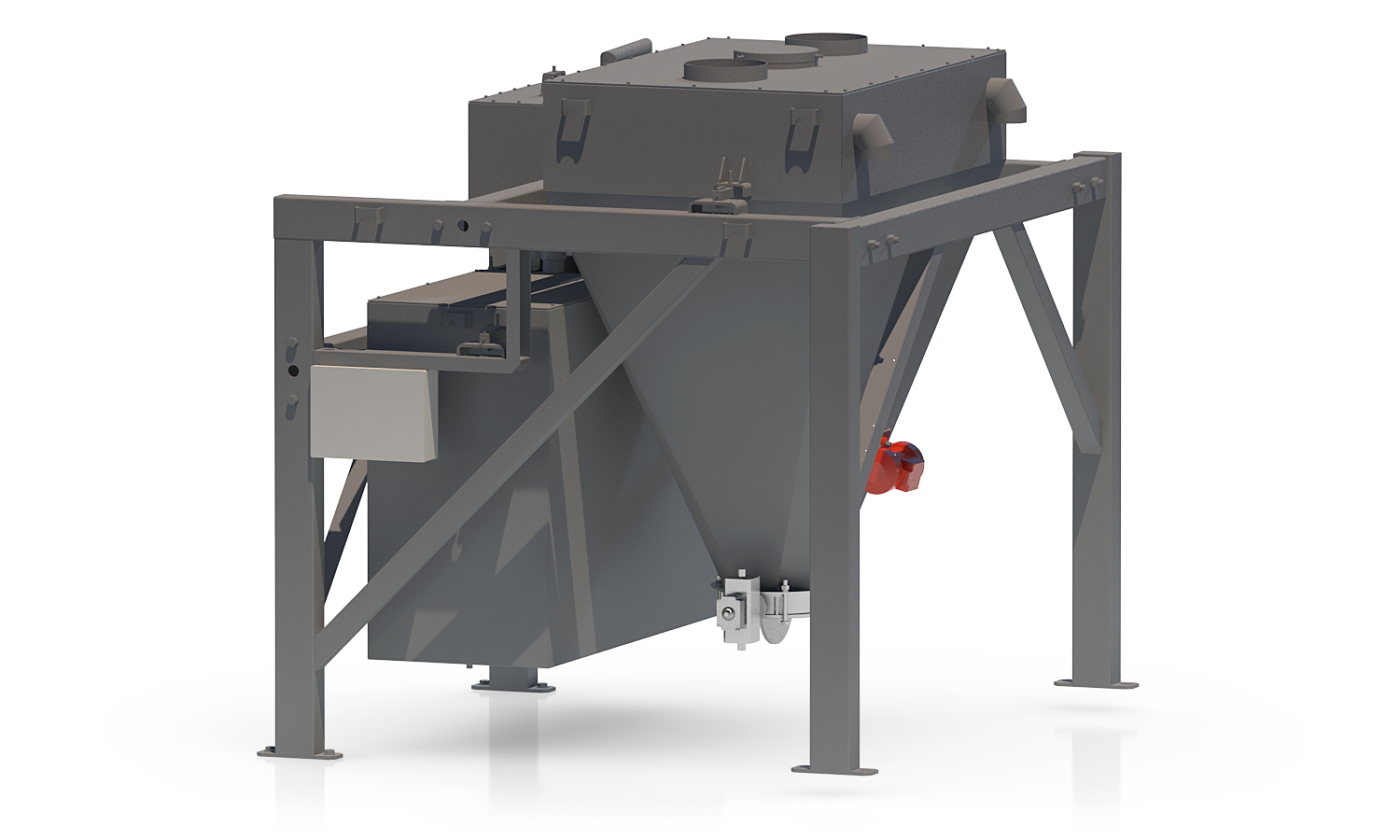

- The total volume of bunkers, the cube. m. 5

- The volume of the hopper, the cube. m. 2,5

- The number of bins, pieces. 2

- The maximum dose weighing kg up to 800

- Batching error,% ±1

- Belt speed, m c 1,3

- The pressure in the pneumatic system, MPa 0,6

83 167

4 793 300

- Capacity, cu m per hour 10...20

- single-shaft mixer БП-1Г-750С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (4 х 8) = 32

- Total power, kW 27

- Sector gate, pneumatic control

- Length, mm 16200

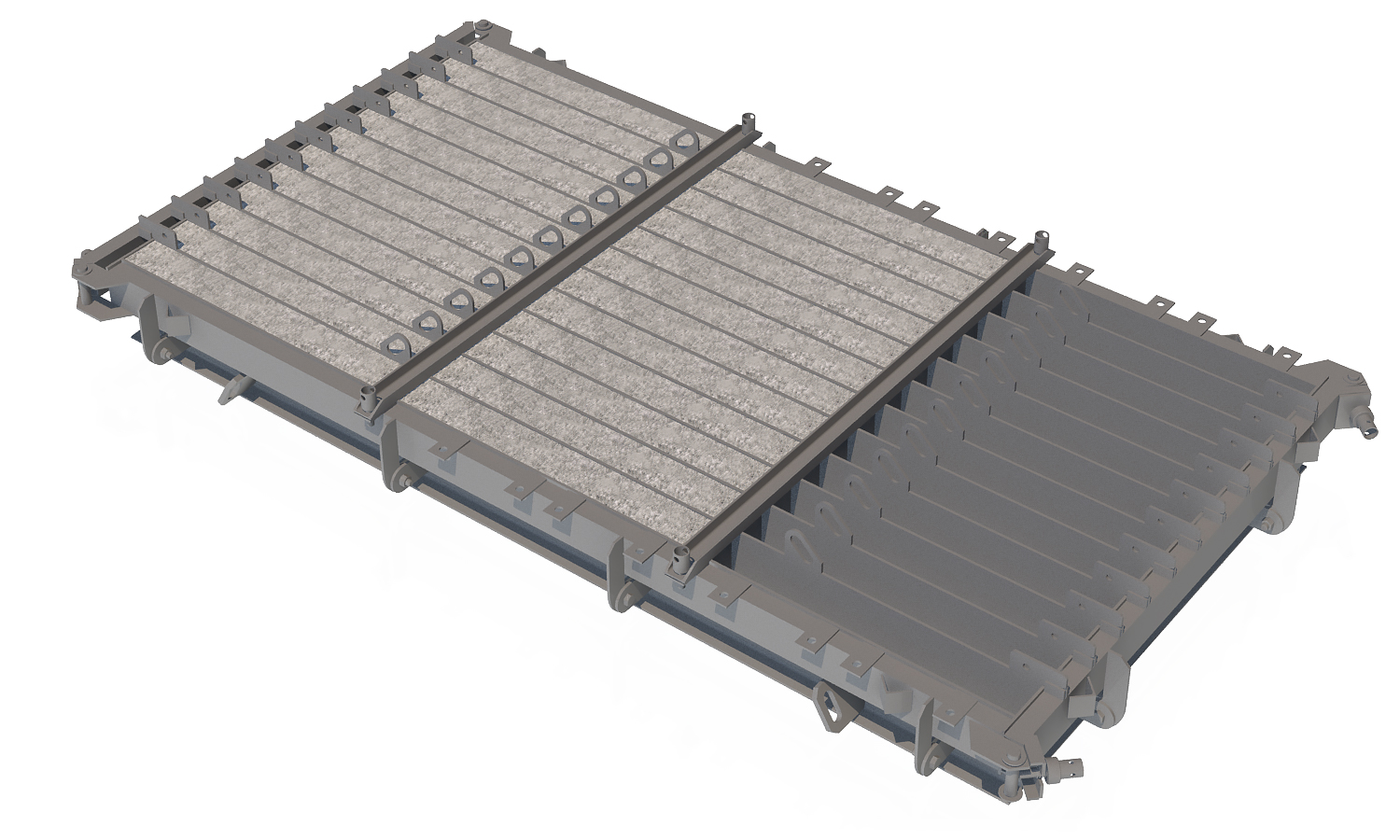

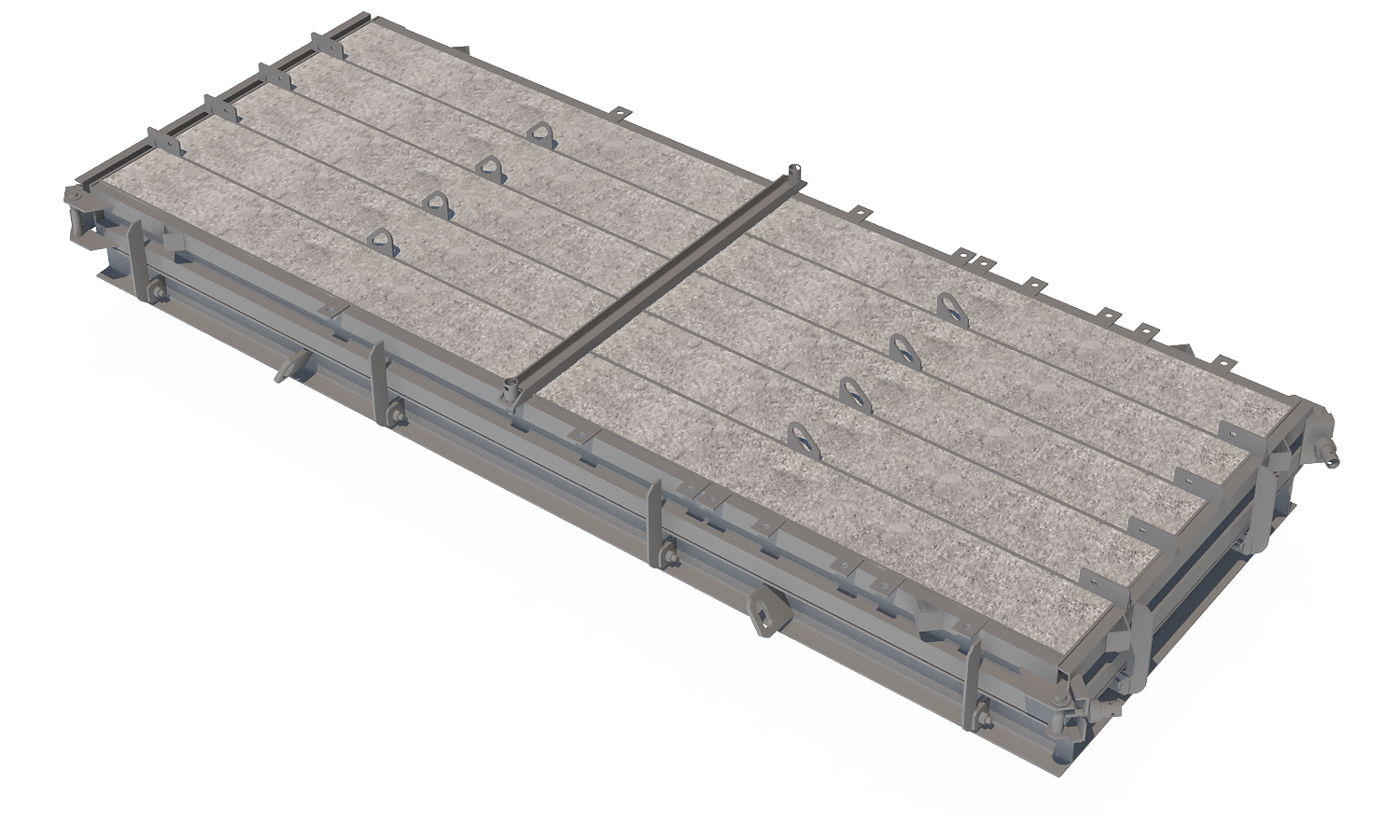

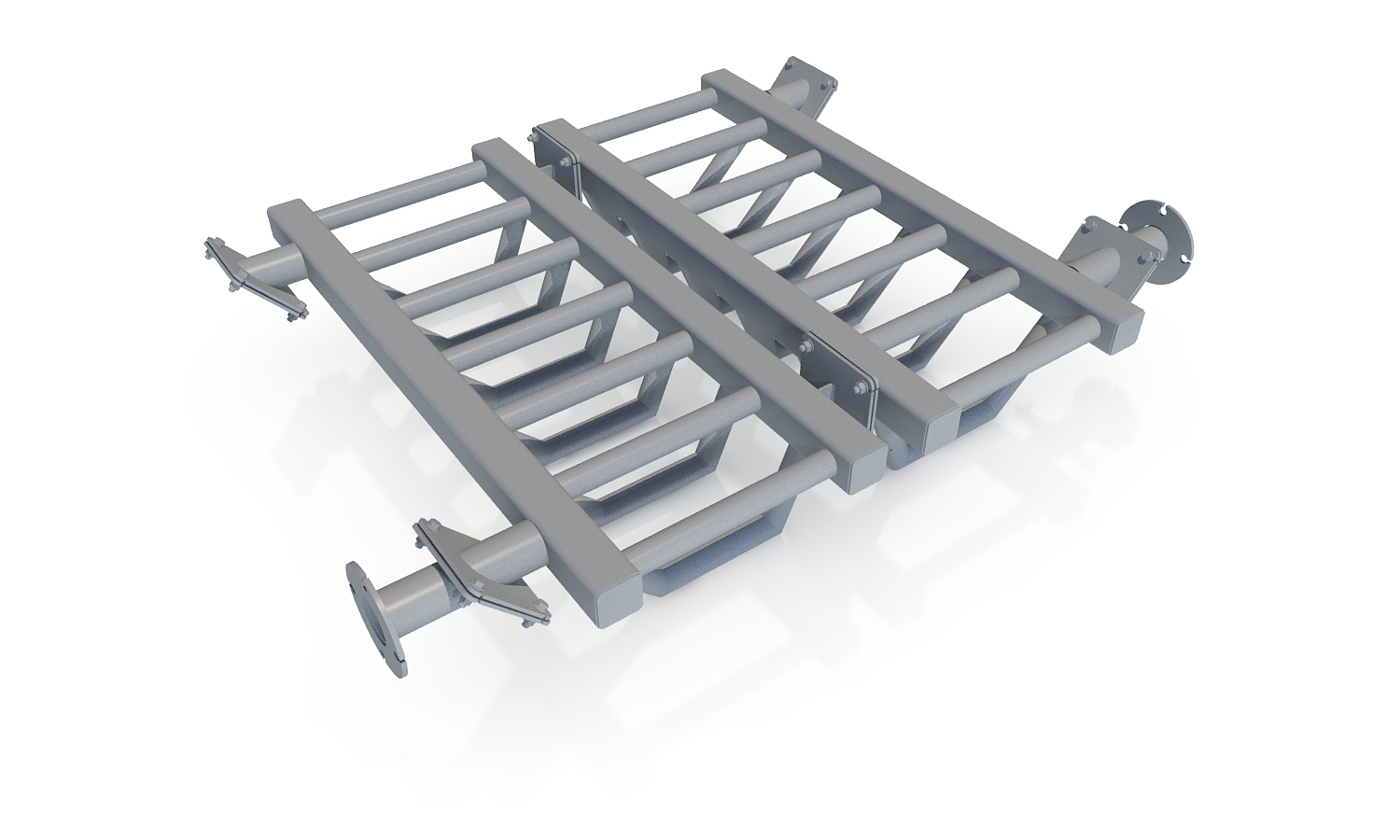

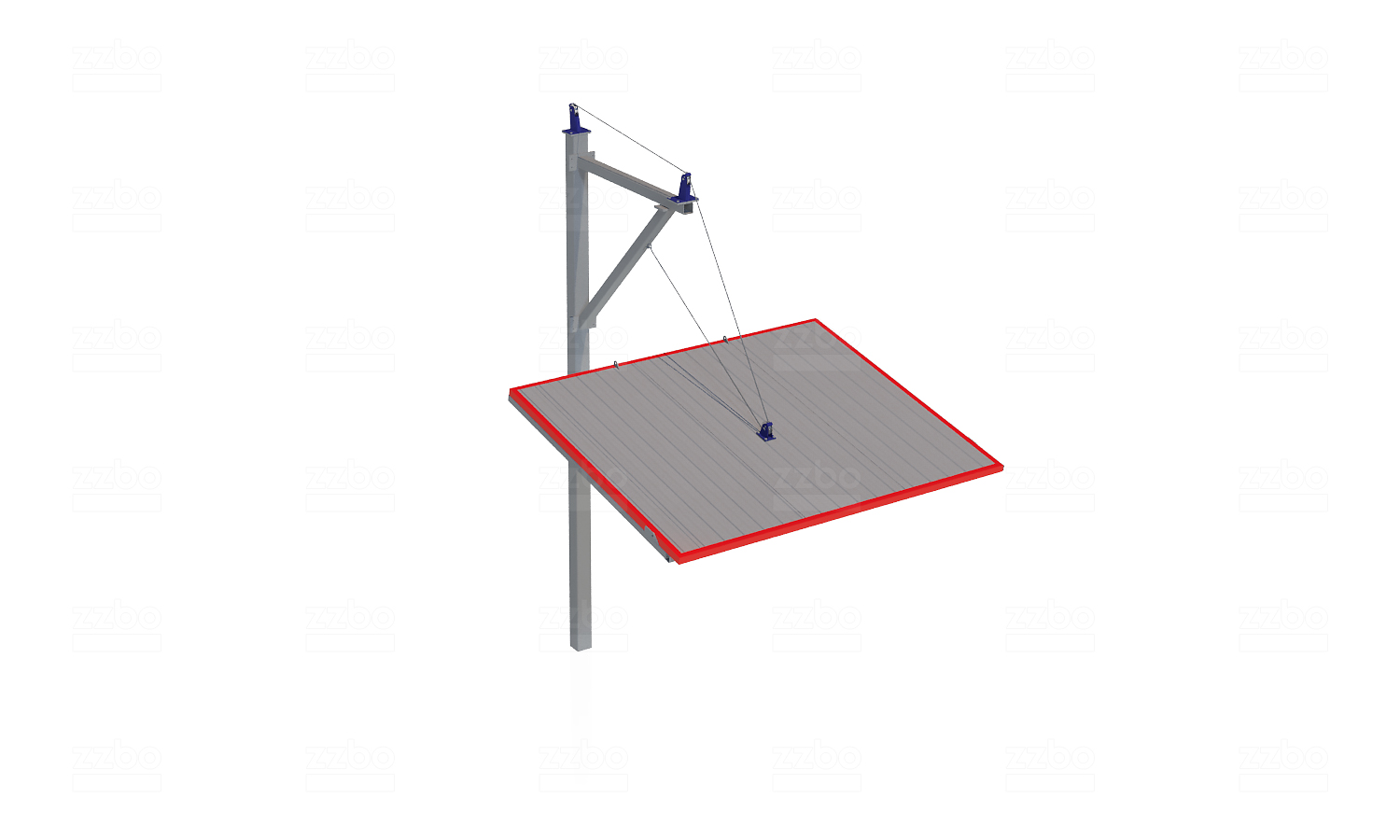

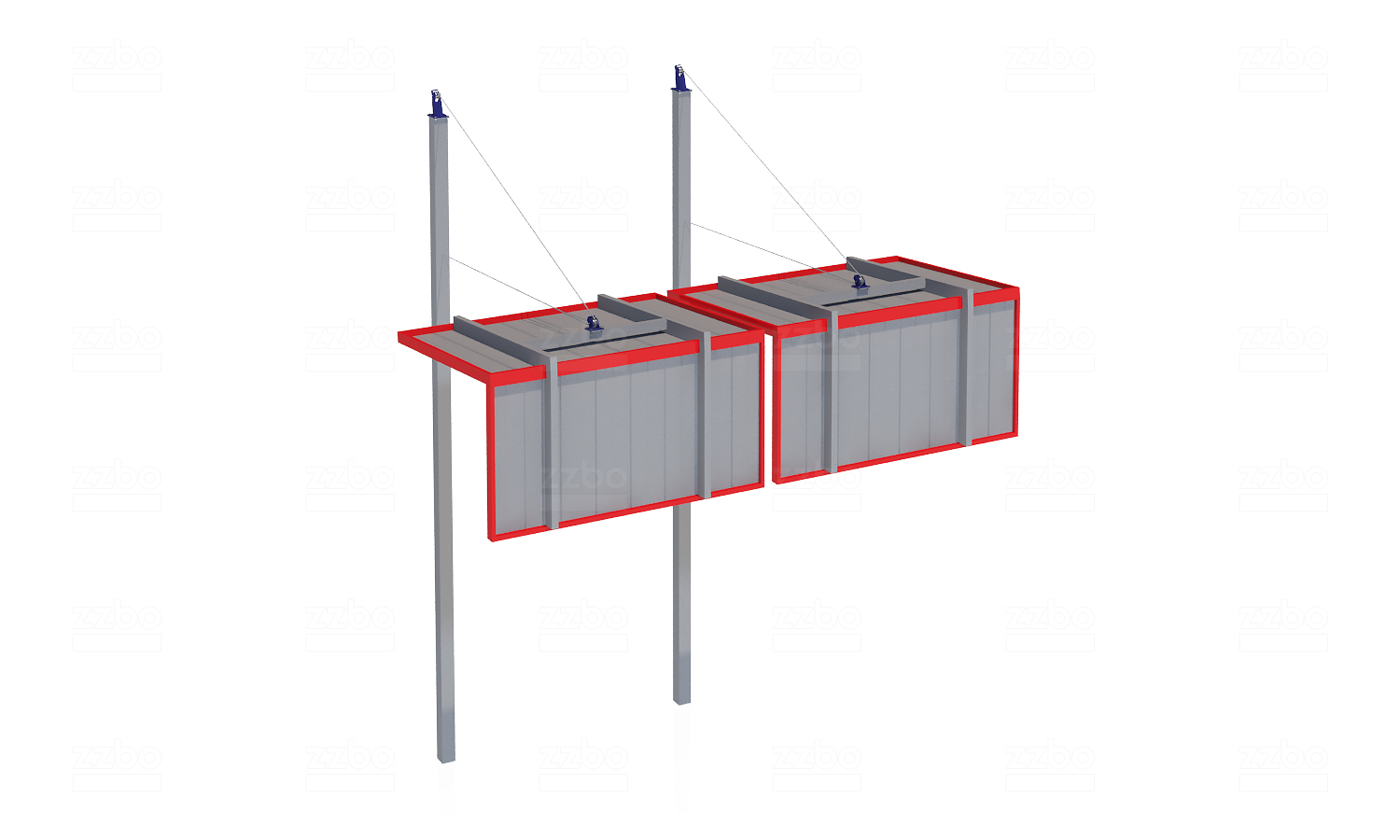

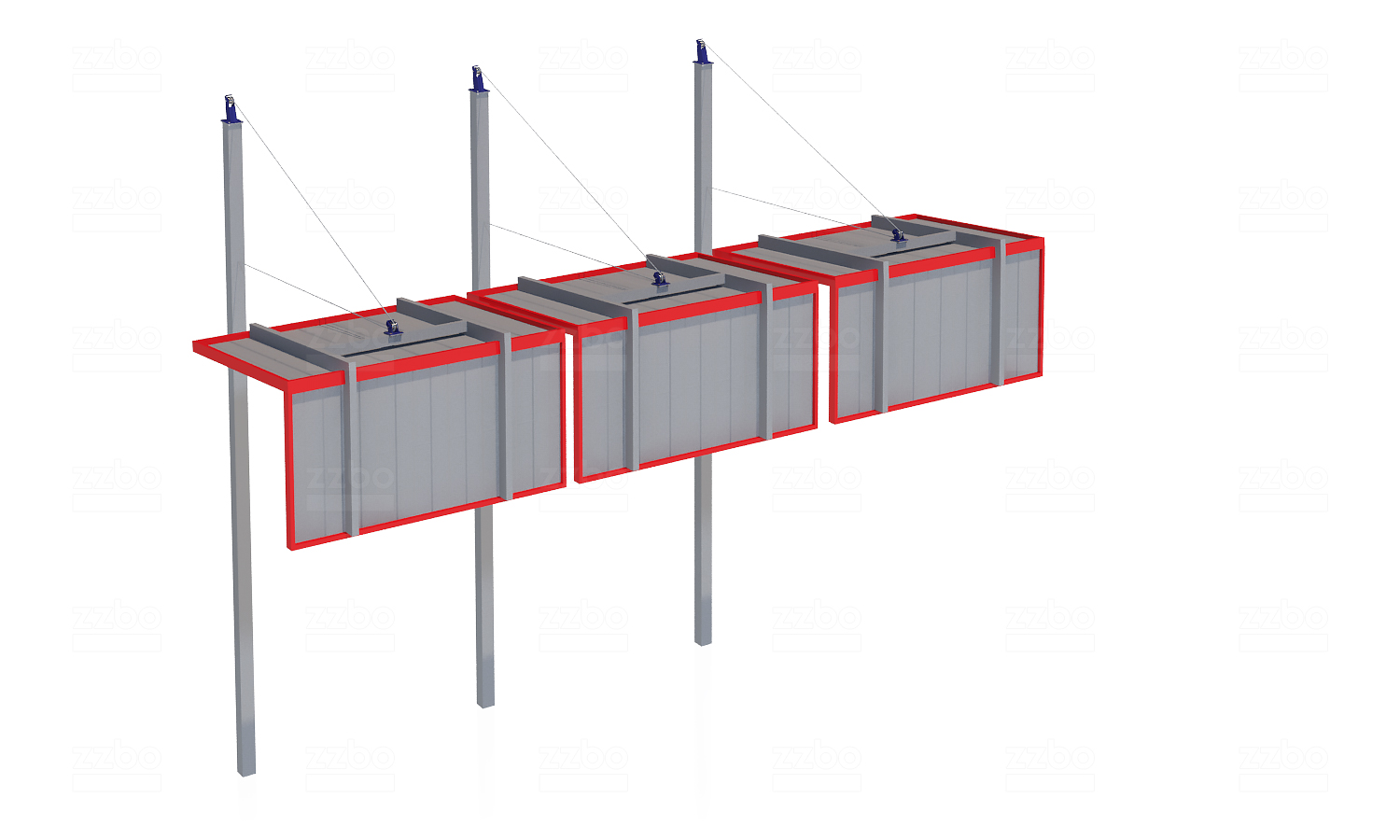

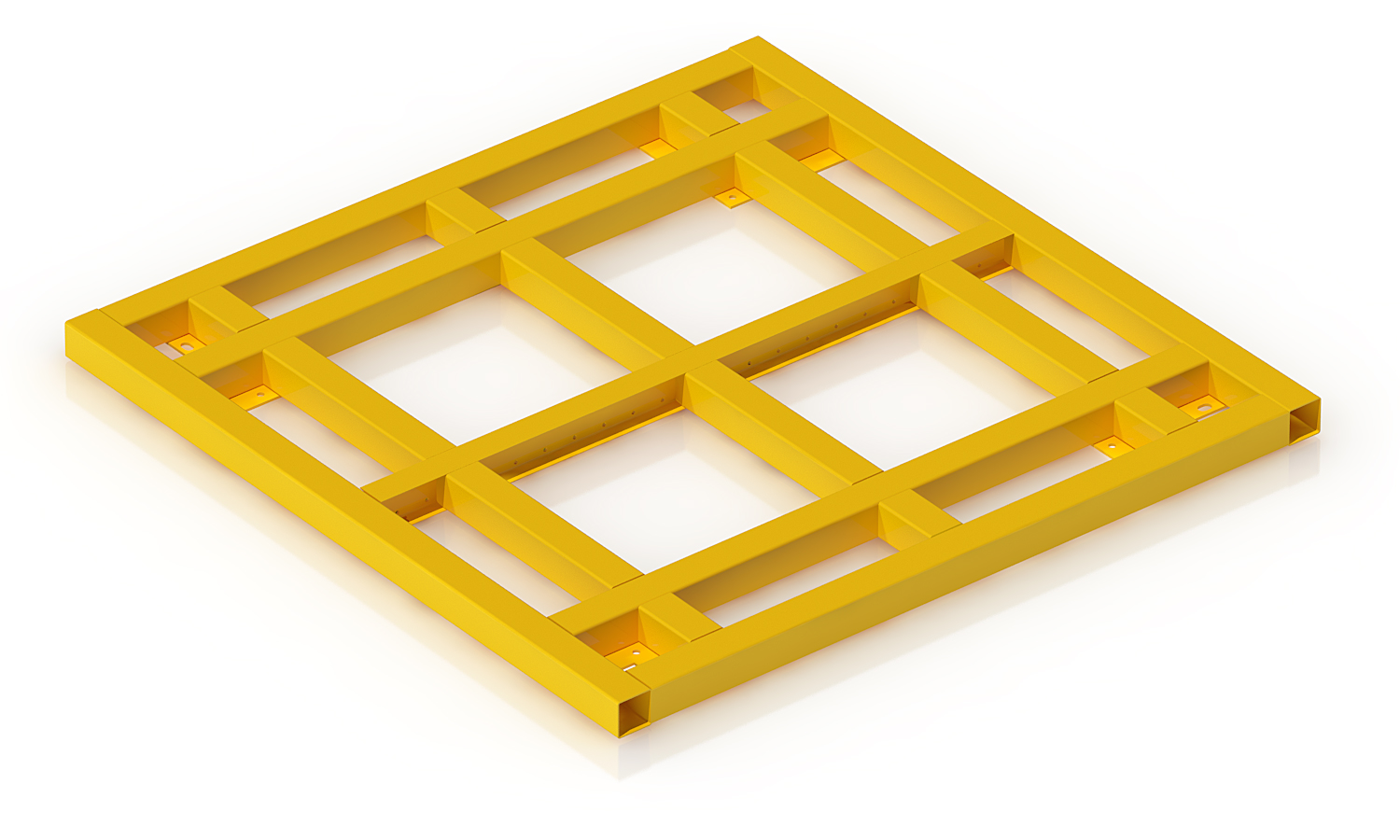

29 200

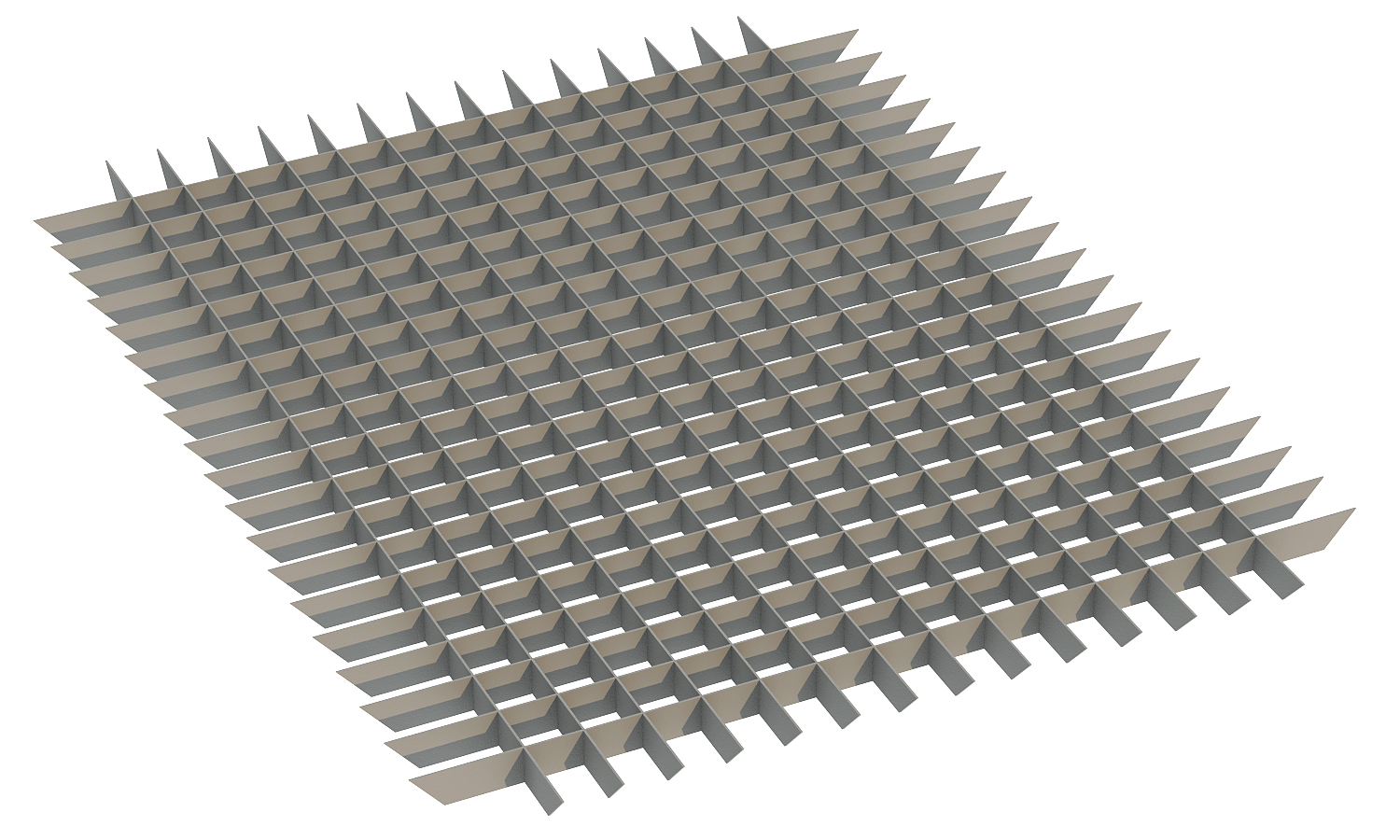

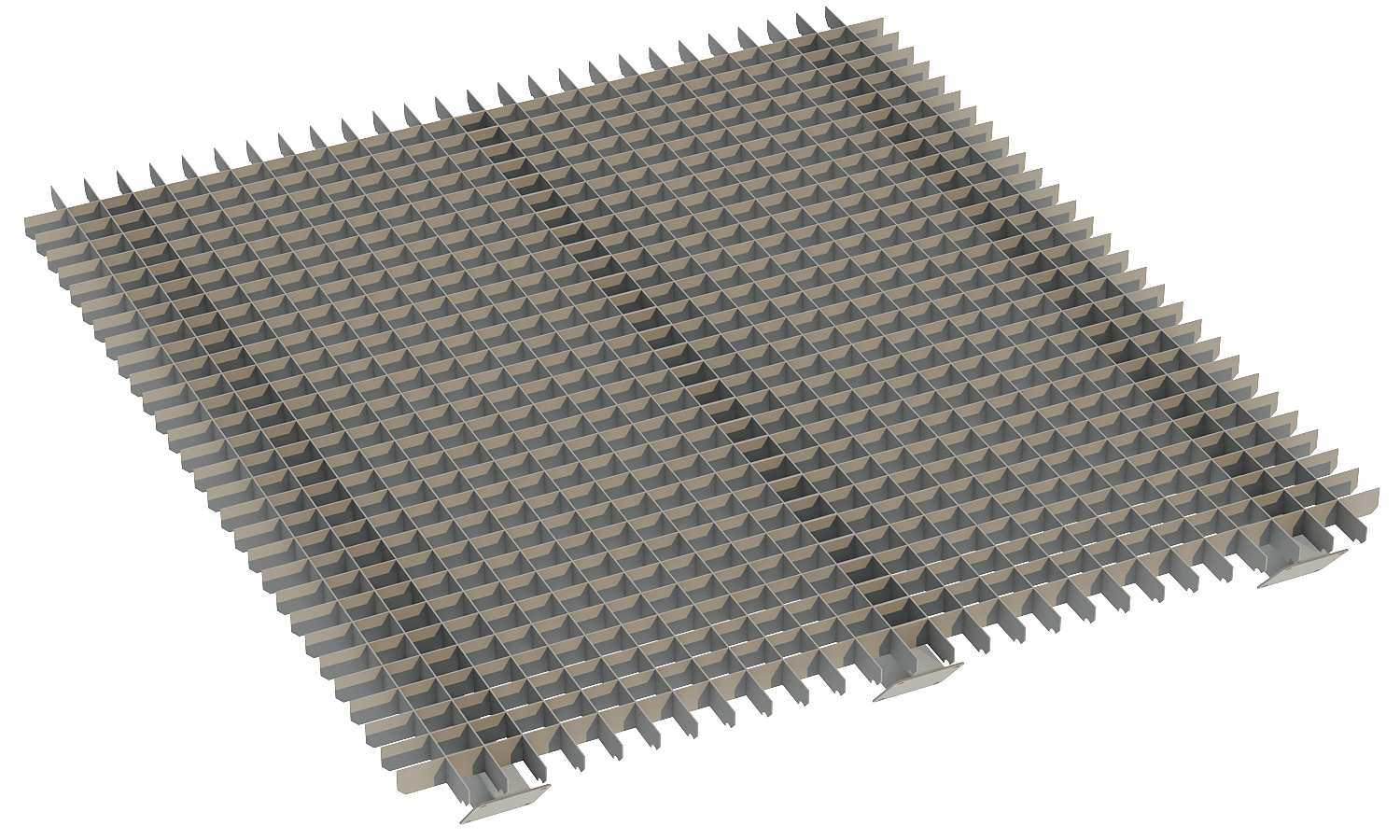

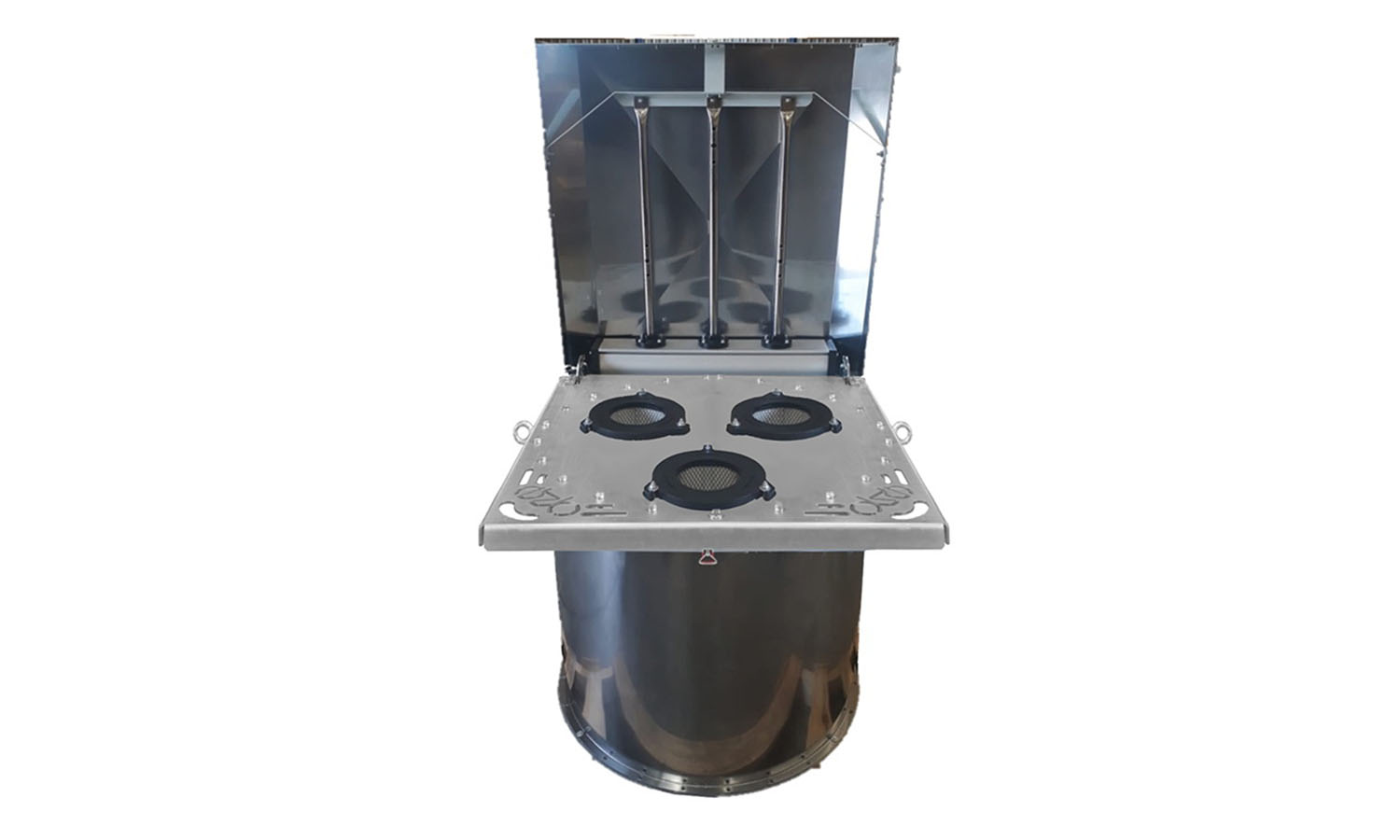

- Grate in hopper section

34 583

- Grate in hopper section

40 800

- Grate in hopper section

41 100

- Grate in hopper section

62 250

- Grate in hopper section

72 300

- Grate in hopper section

53 000

- Grate in hopper section

102 500

- Grate in hopper section

127 100

- Grate in hopper section

125 400

- Grate in hopper section

5 006 900

- Capacity, cu m per hour 10...20

- single-shaft mixer Single Shaft Concrete Mixer

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (2 х 8) = 16

- Total power, kW 23

- Sector gate, pneumatic control

- Height, mm 10400

5 439 300

- Capacity, cu m per hour 10...20

- single-shaft mixer БП-1Г-750С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (3 х 8) = 24

- Total power, kW 32

- Sector gate, pneumatic control

- Length, mm 14400

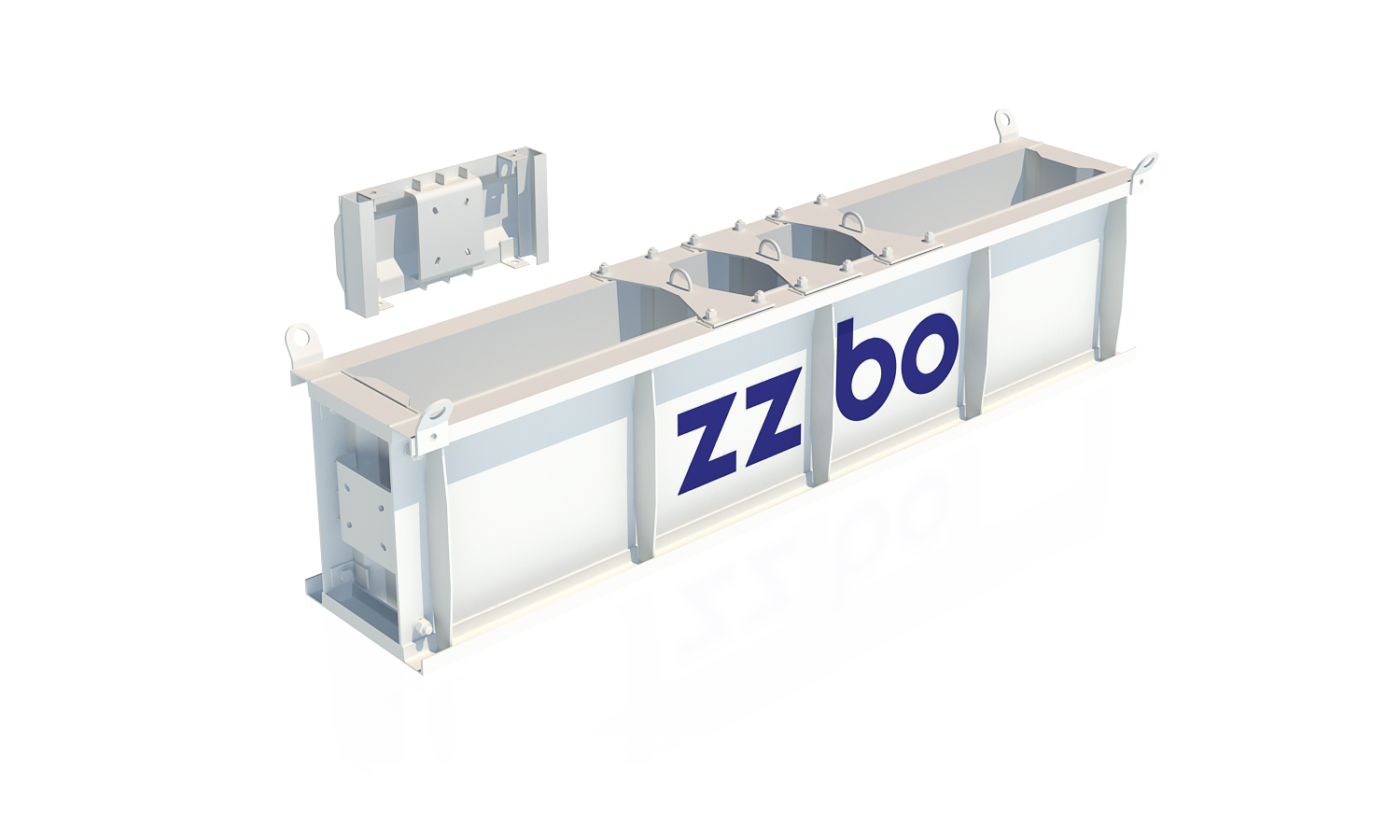

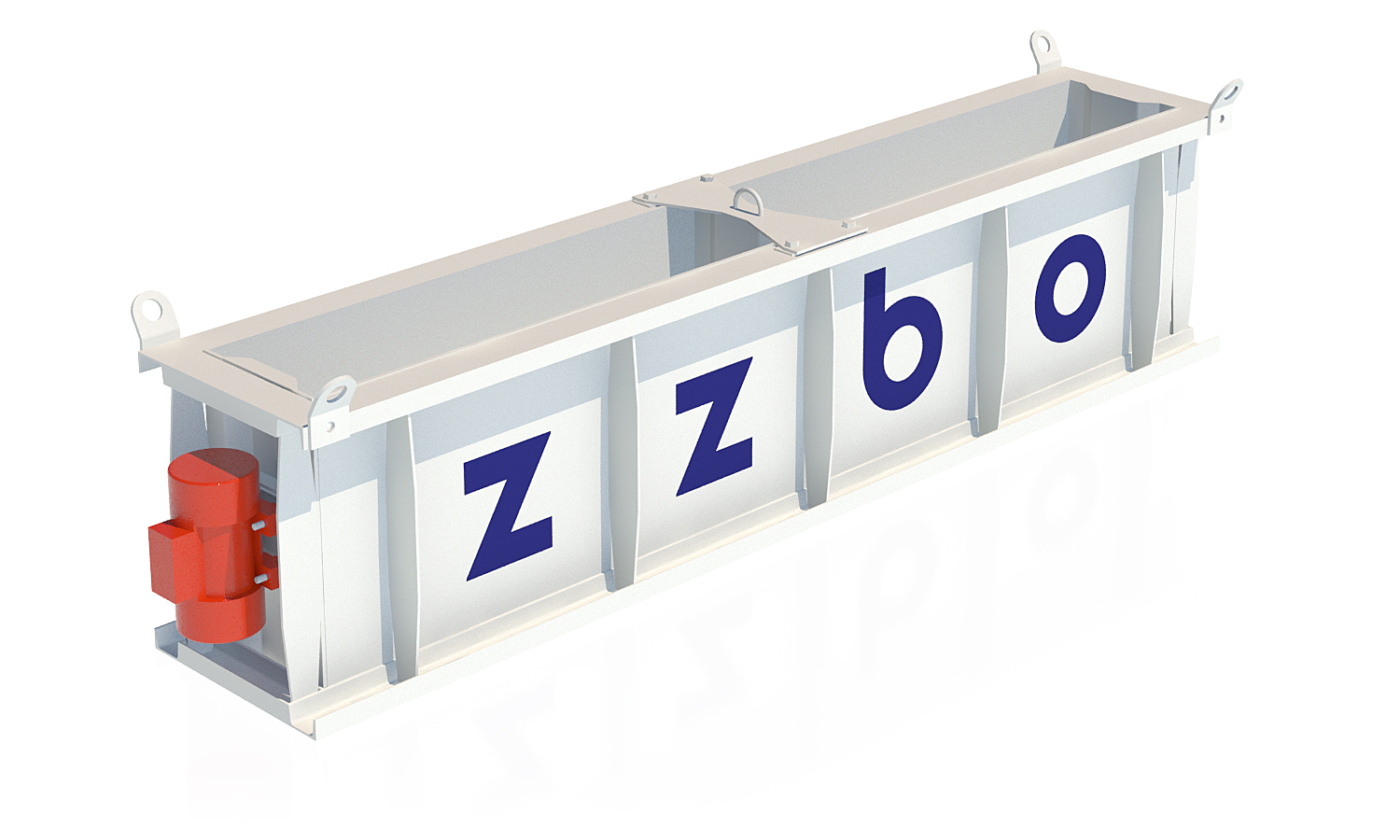

131 800

- Grate in hopper section

232 000

- Grate in hopper section

163 800

189 600

124 300

84 200

202 100

394 800

647 600

651 500

1 860 700

2 929 900

4 087 700

4 544 400

5 795 500

- Capacity, cu m per hour 20...30

- single-shaft mixer БП-1Г-750С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (4 х 8) = 32

- Total power, kW 36

- Sector gate, pneumatic control

- Length, mm 17300

862 900

- The total volume of bunkers, the cube. m. 10

- The volume of the hopper, the cube. m. 5

- The number of bins, pieces. 2

- The maximum dose weighing kg to 1200

- Batching error,% ±1

- Belt speed, m c 1,3

- The pressure in the pneumatic system, MPa 0,6

1 559 800

1 250 000

- The total volume of bunkers, the cube. m. 12

- The number of bins, pieces. 2

- The volume of each bunker, cub. m. 84

- The maximum dose weighing kg up to 1000

- Batching error,% ±1

- Belt speed, m c 0,9

- The pressure in the pneumatic system, MPa 0,6...0,8

1 384 300

1 333 333

- The total volume of bunkers, the cube. m. 16

- The volume of the hopper, the cube. m. 8

- The number of bins, pieces. 2

- The maximum dose weighing kg to 1500

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

1 628 600

- The total volume of bunkers, the cube. m. 16

- The volume of the hopper, the cube. m. 8

- The number of bins, pieces. 2

- The maximum dose weighing kg to 1500

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

1 751 900

1 708 333

- The total volume of bunkers, the cube. m. 24

- The volume of the hopper, the cube. m. 8

- The number of bins, pieces. 3

- The maximum dose weighing kg to 2000

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

5 053 900

- Capacity, cu m per hour 20...30

- single-shaft mixer Single Shaft Concrete Mixer

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (2 х 8) = 16

- Total power, kW 32

- Sector gate, pneumatic control

- Weight, kg 10260

2 061 000

- The total volume of bunkers, the cube. m. 24

- The volume of the hopper, the cube. m. 8

- The number of bins, pieces. 3

- The maximum dose weighing kg to 2000

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

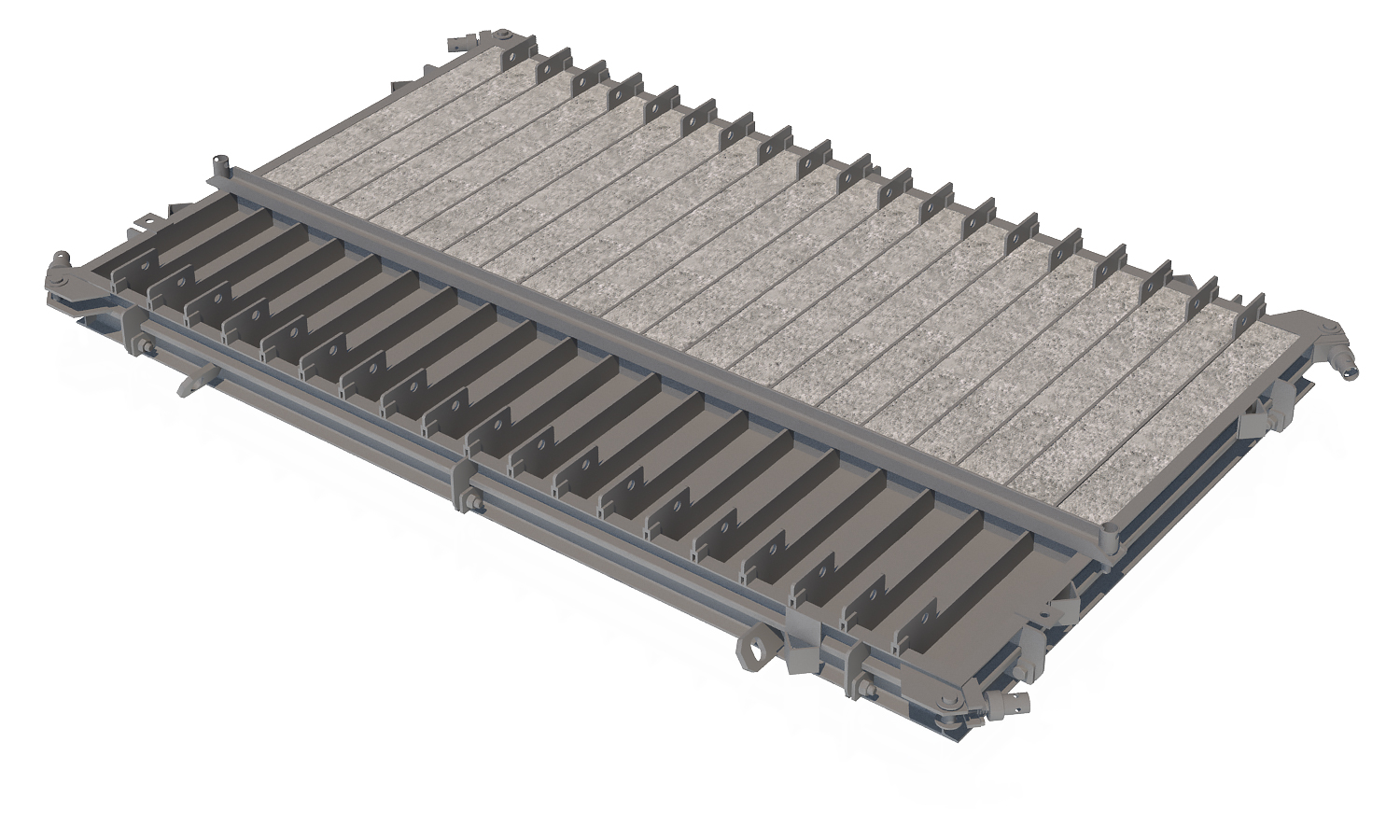

2 417 200

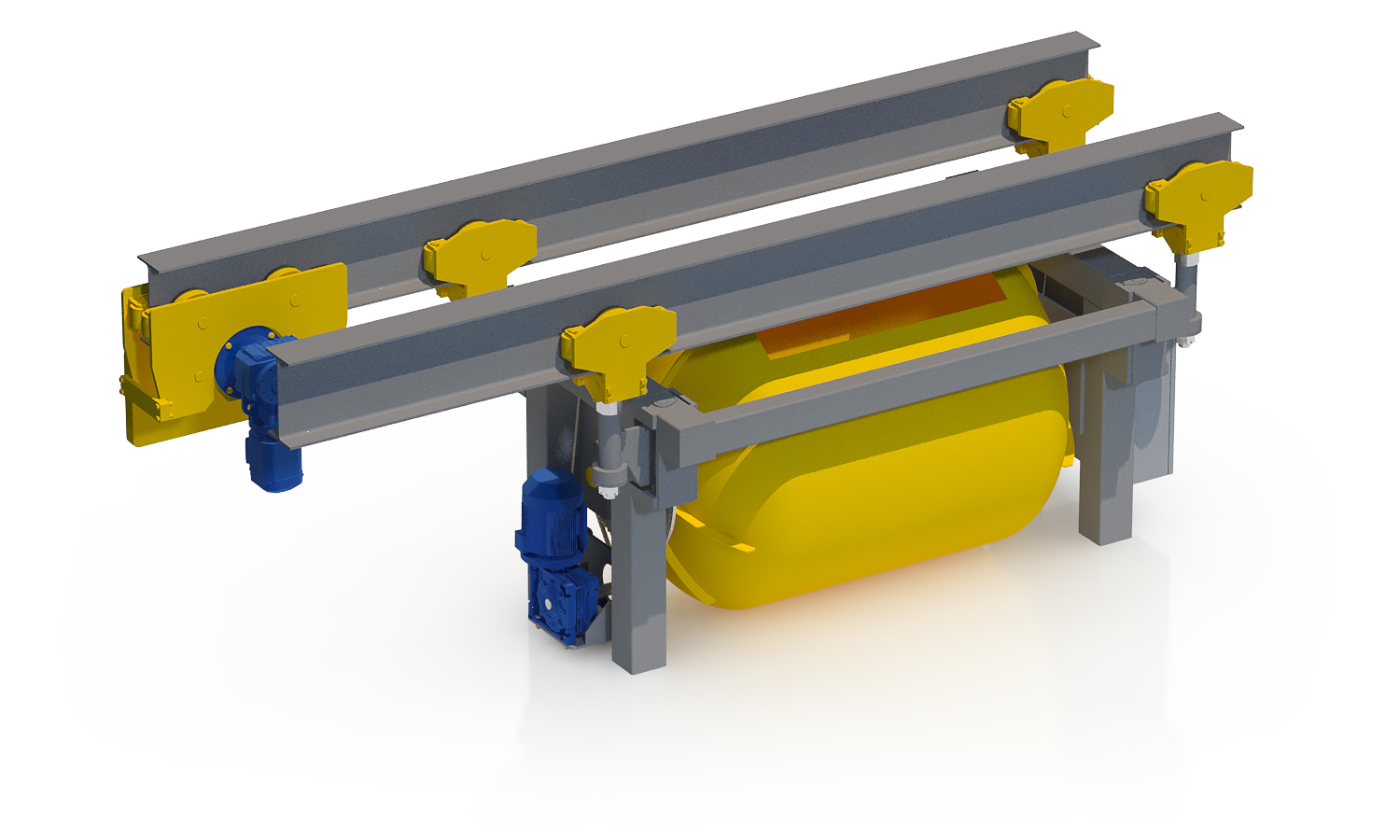

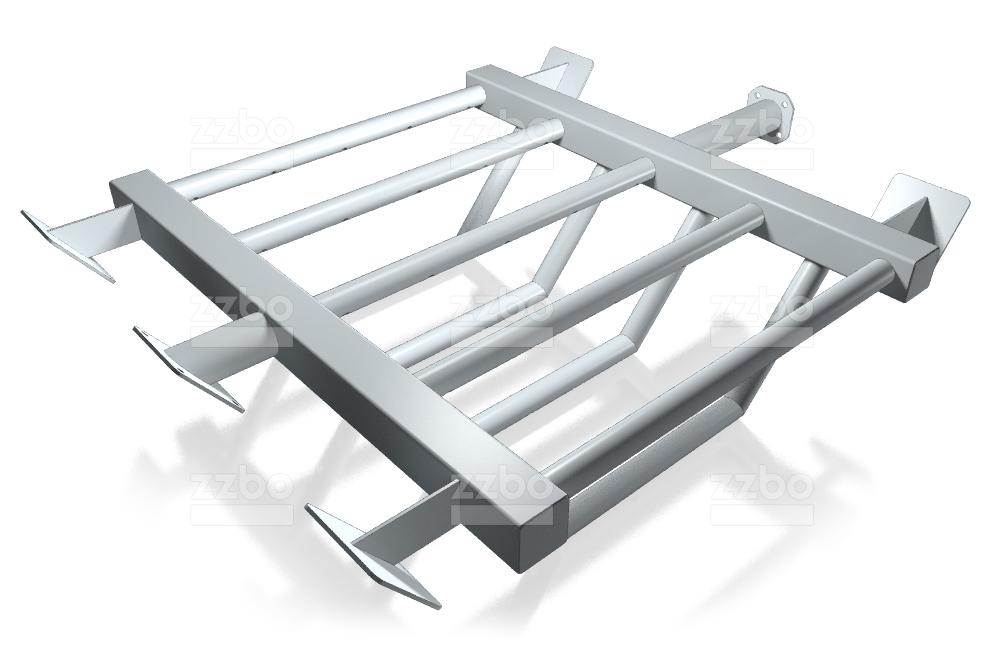

- Total volume of bunkers, m³ 32

- Volume of one bunker, m³ 8

- The number of bins, pieces. 4

- Мощность привода ленточного конвейера, кВт 11

- The width of the conveyor belt, mm 800

- Угол наклона конвейера, ° 4,5

- Скорость движения ленты, м/с 1,3

2 257 900

- Total volume of bunkers, m³ 32

- Volume of one bunker, m³ 8

- The number of bins, pieces. 4

- The maximum dose weighing kg 14 910 $

- Batching error,% ±1

- Belt speed, m c 1

- The pressure in the pneumatic system, MPa 0,6

4 143 200

- Vibrator power, kW 5

- Vibrator power, kW 8

- Vibrator power, kW 2,2

- Vibrator power, kW 500

- Maximum productivity of the belt feeder, t/h Operating thermal power of the burner, MW

- Maximum productivity of the belt feeder, t/h 0Vibrator power, kW

- Maximum productivity of the belt feeder, t/h 7.5

1 985 400

- Total volume of bunkers, m³ 40

- Volume of one bunker, m³ 20

- Vibrator power, kW 2

- The maximum dose weighing kg 14 910 $

- Batching error,% ±1

- Belt speed, m c 1,9

- The pressure in the pneumatic system, MPa 0,6...0,8

2 492 200

- The total volume of bunkers, the cube. m. 60

- The volume of the hopper, the cube. m. 20

- The number of bins, pieces. 3

- The maximum dose weighing kg до 4500

- Batching error,% ±1

- Belt speed, m c 1,9

- The pressure in the pneumatic system, MPa 0,6...0,8

3 297 750

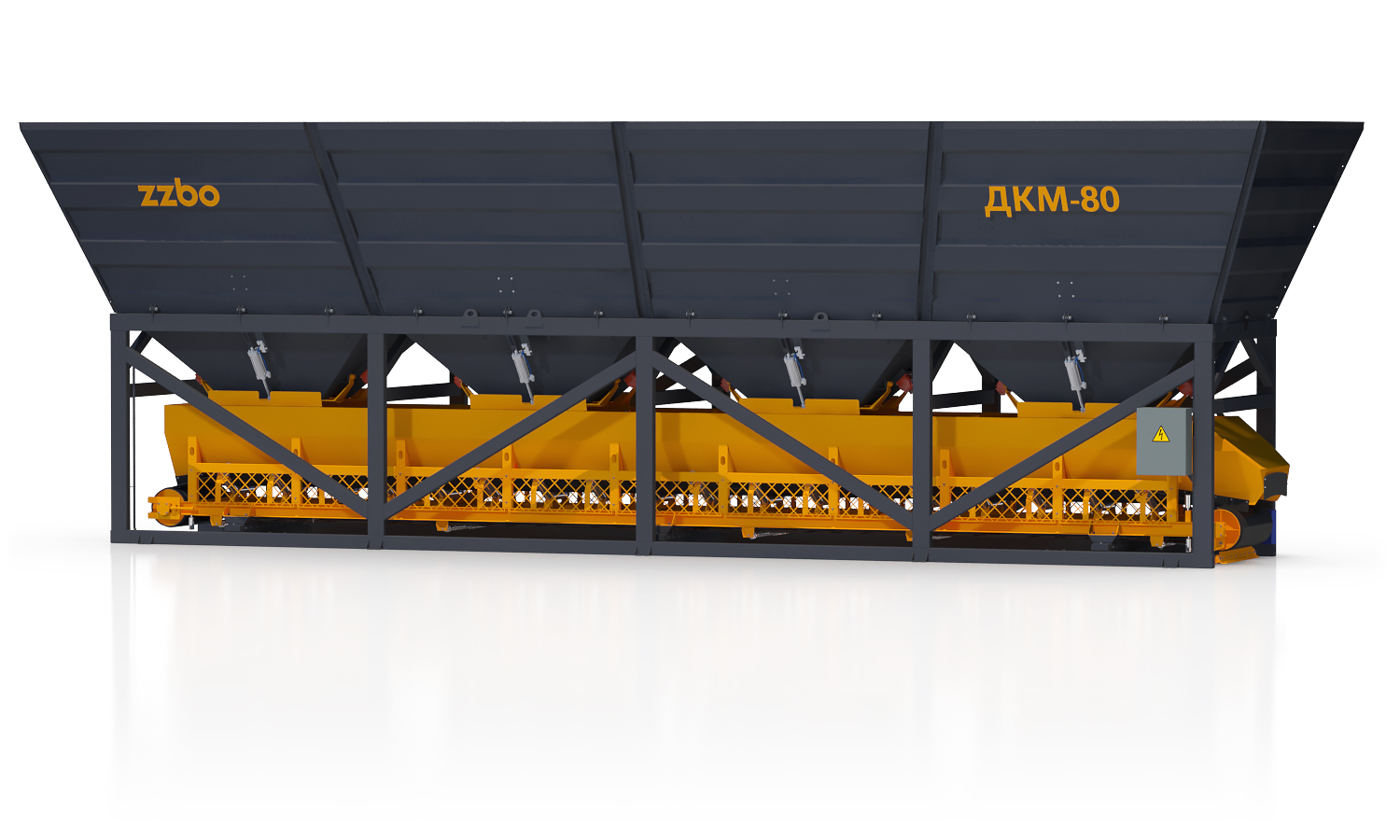

- Total volume of bunkers, m³ 80

- Volume of one bunker, m³ 20

- Vibrator power, kW 4

- The maximum dose weighing kg 6000

- Batching error,% ±1

- Belt speed, m c 1,9

- The pressure in the pneumatic system, MPa 0,6...0,8

4 119 100

3 500 000

- Total volume of bunkers, m³ 120

- Volume of one bunker, m³ 30

- Vibrator power, kW 4

- Batching error,% ±1

- Скорость движения ленты, м/с 1,4

- The pressure in the pneumatic system, MPa 0,6...0,8

- Aggregate size, mm max 70

2 178 500

- The total maximum amount of bunkers, the cube. m. 24

- The volume of the hopper, the cube. m. 12

- The number of bins, pieces. 2

- The maximum dose weighing kg 1500 kg

- Batching error,% 1

- Belt speed, m c 1,6

- The pressure in the pneumatic system, MPa 0,6...0,8

5 486 300

- Capacity, cu m per hour 20...30

- single-shaft mixer Single Shaft Concrete Mixer

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (3 х 8) = 24

- Total power, kW 32

- Weight, kg 11540

- Length, mm 14653

2 681 800

- The total maximum amount of bunkers, the cube. m. 36

- The volume of the hopper, the cube. m. 12

- The number of bins, pieces. 3

- The maximum dose weighing kg 2,500

- Batching error,% 1

- Belt speed, m c 1,6

- The pressure in the pneumatic system, MPa 0,6...0,8

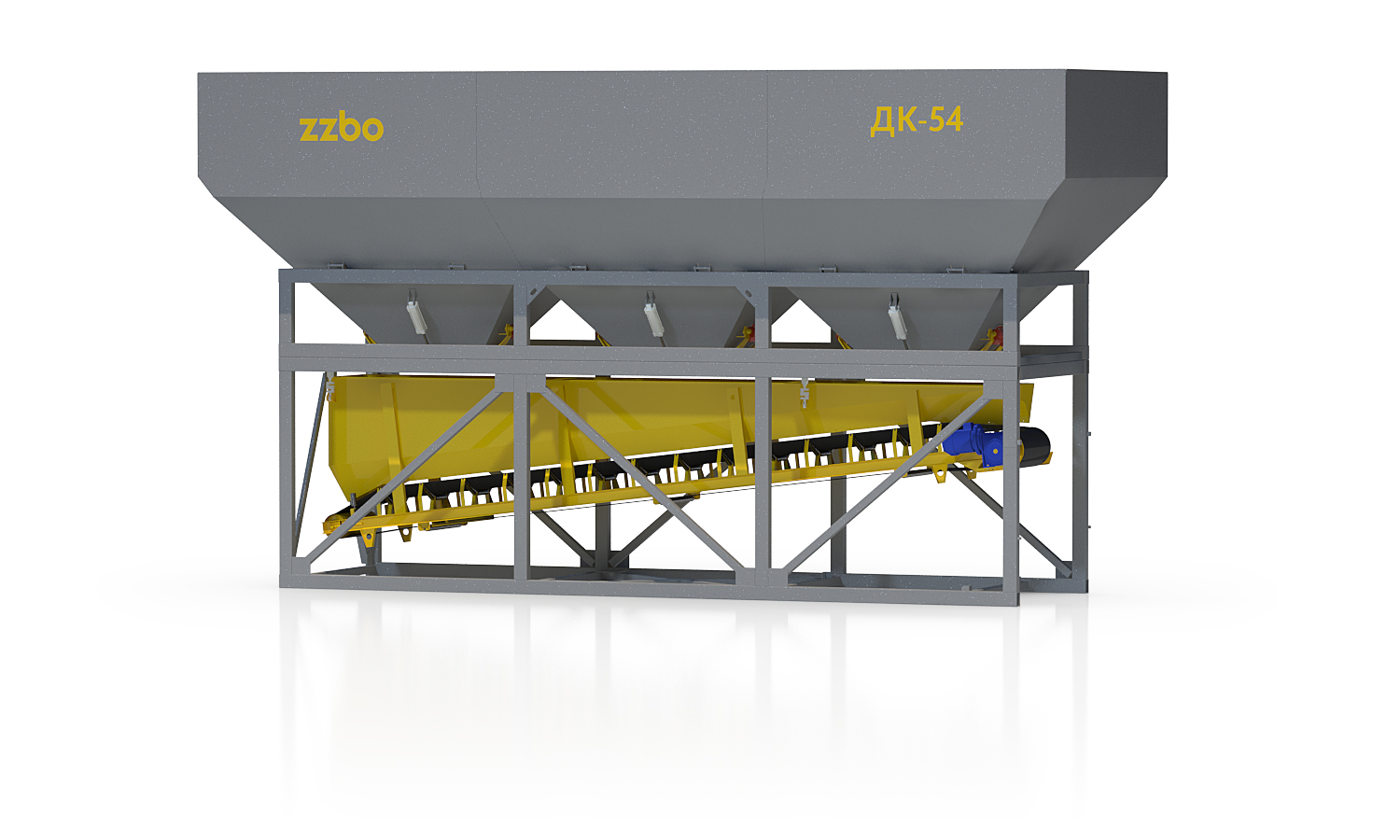

2 848 400

- Total maximum volume of bunkers, m³ 54

- Volume of one bunker, m³ 18

- The number of bins, pieces. 3

- The maximum dose weighing kg 3,000

- Batching error,% 1

- Belt speed, m c 1,6

- The pressure in the pneumatic system, MPa 0,6...0,8

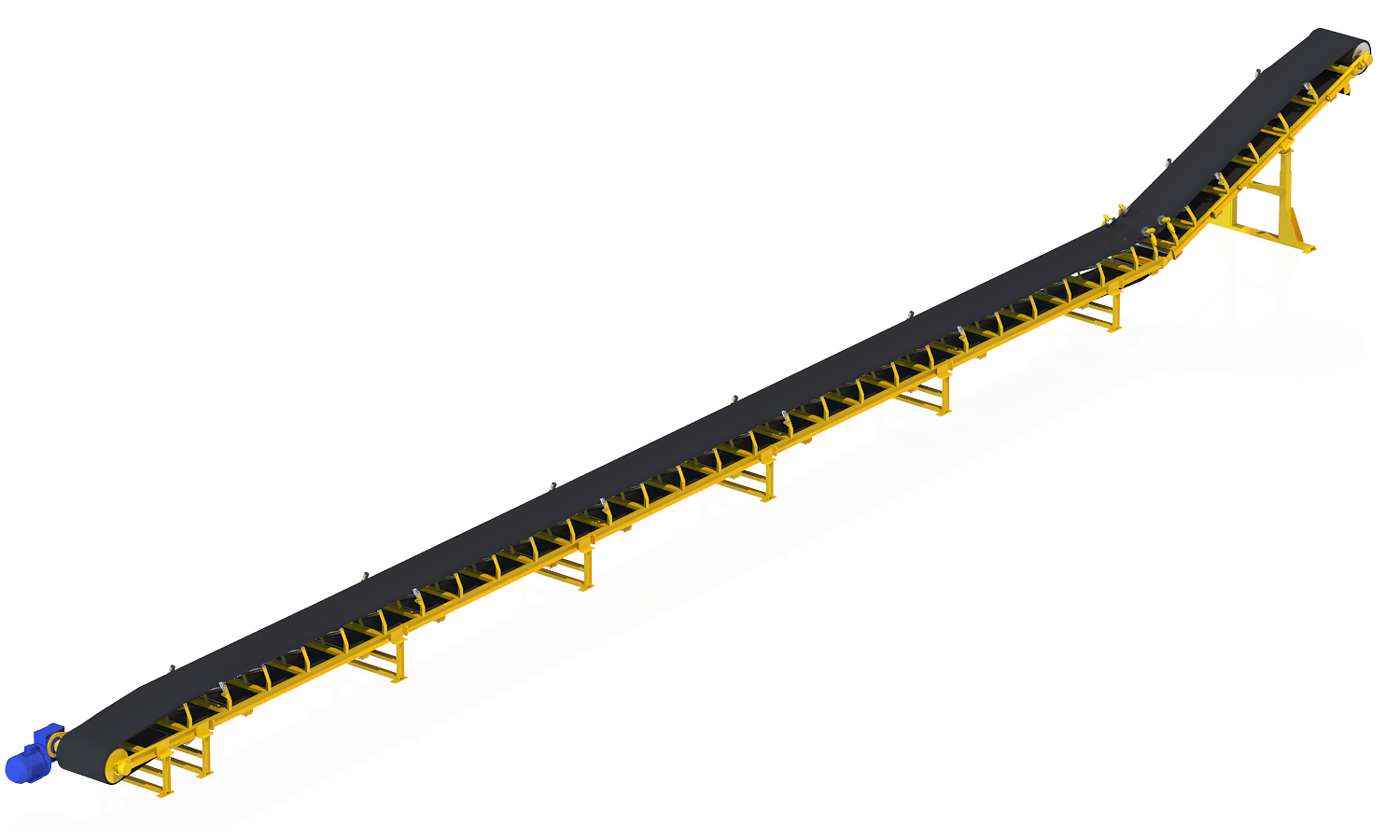

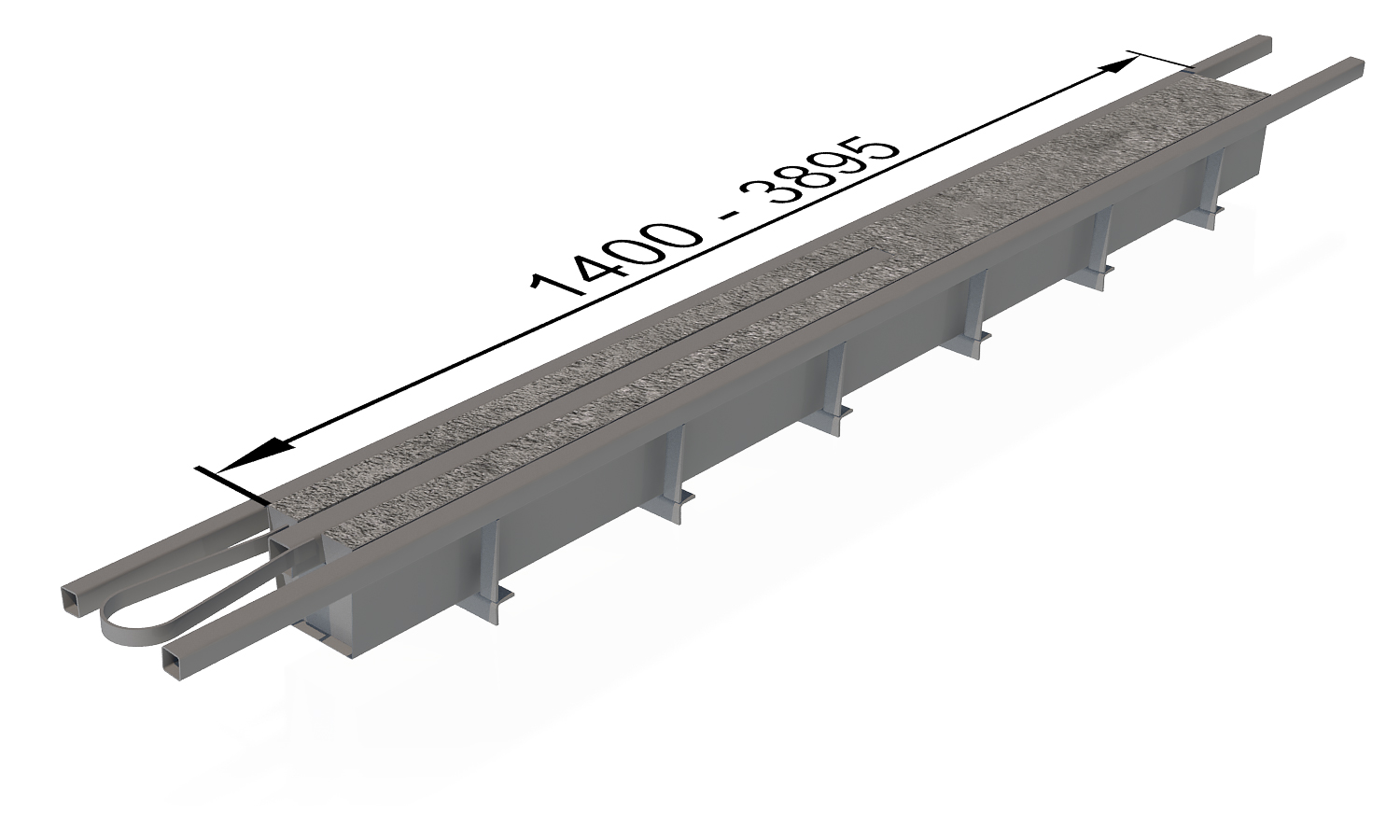

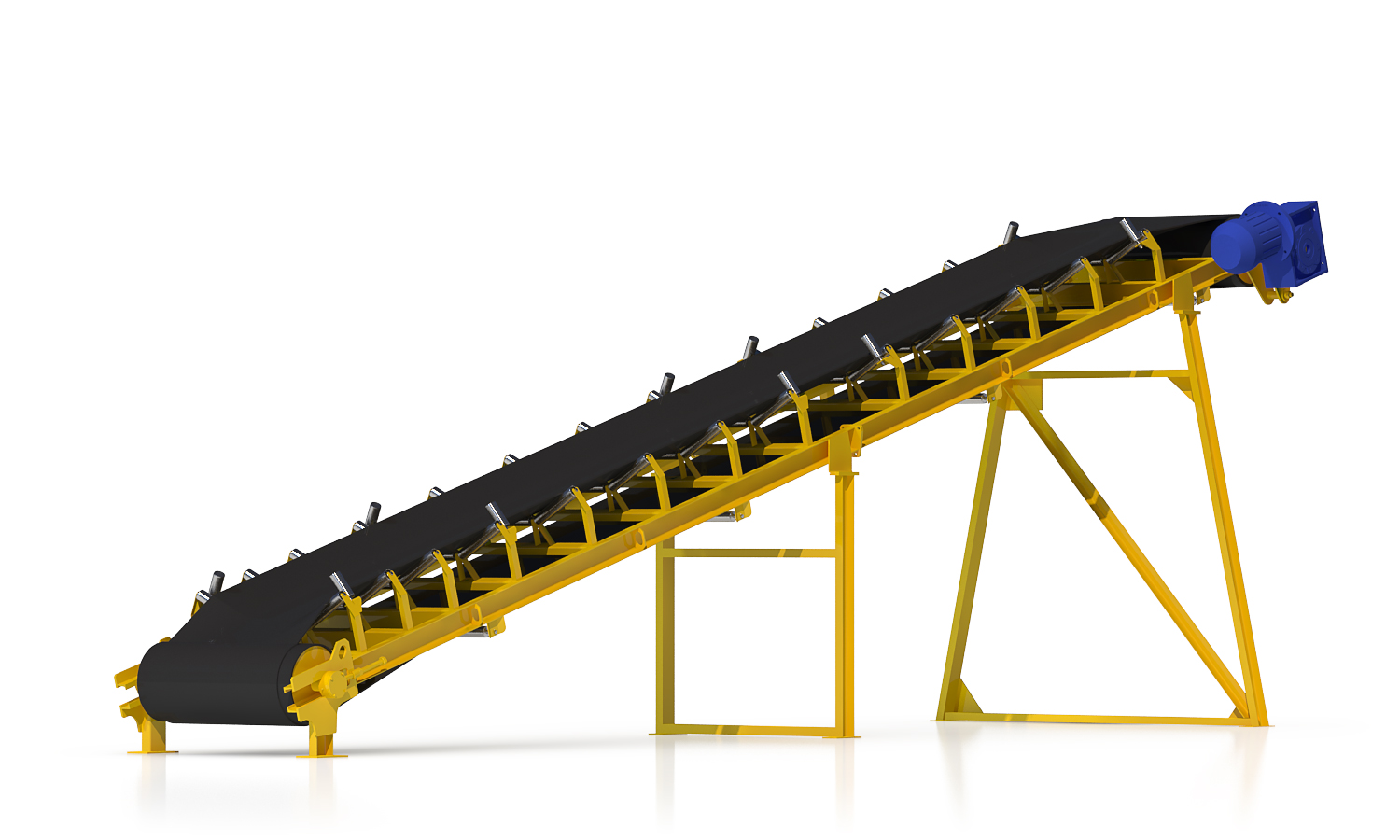

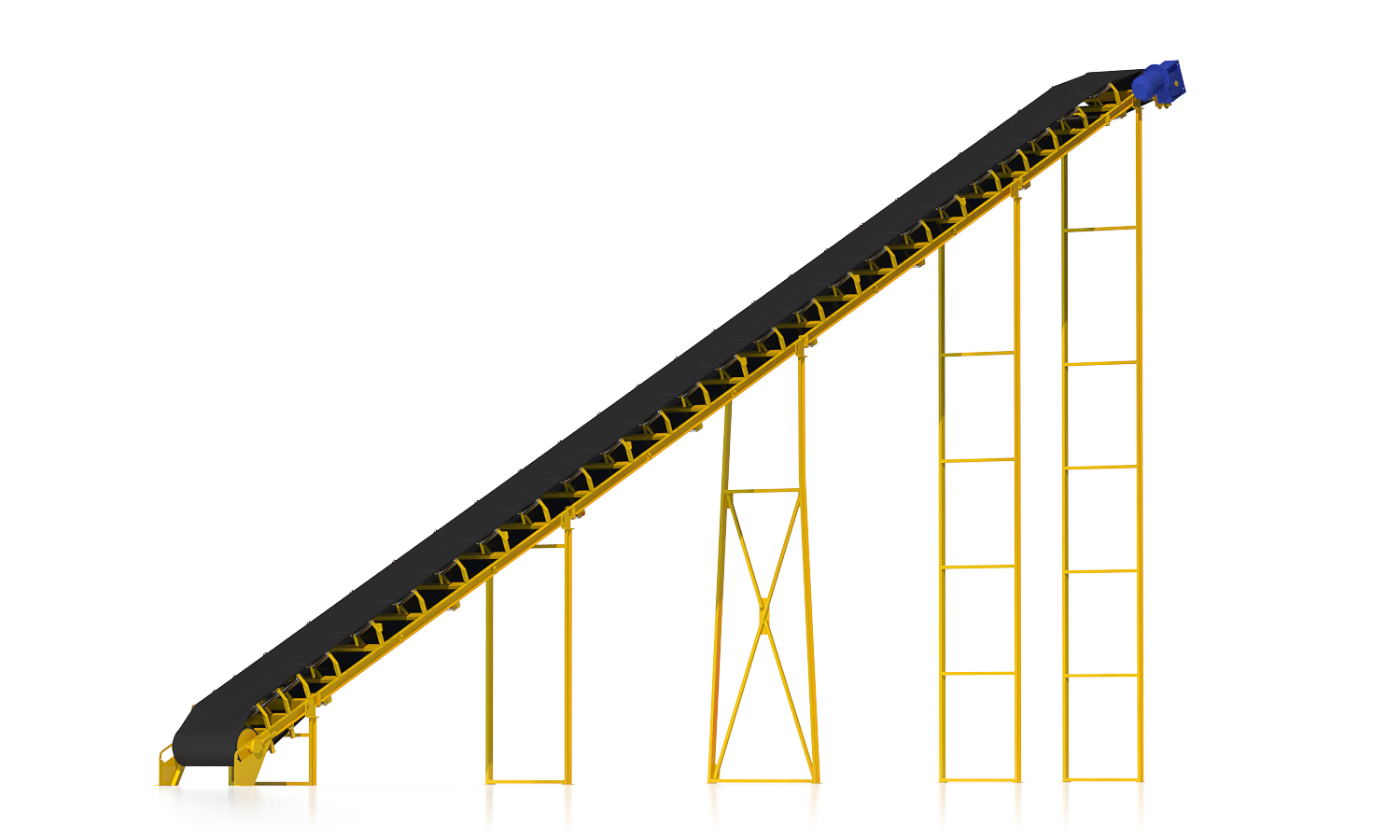

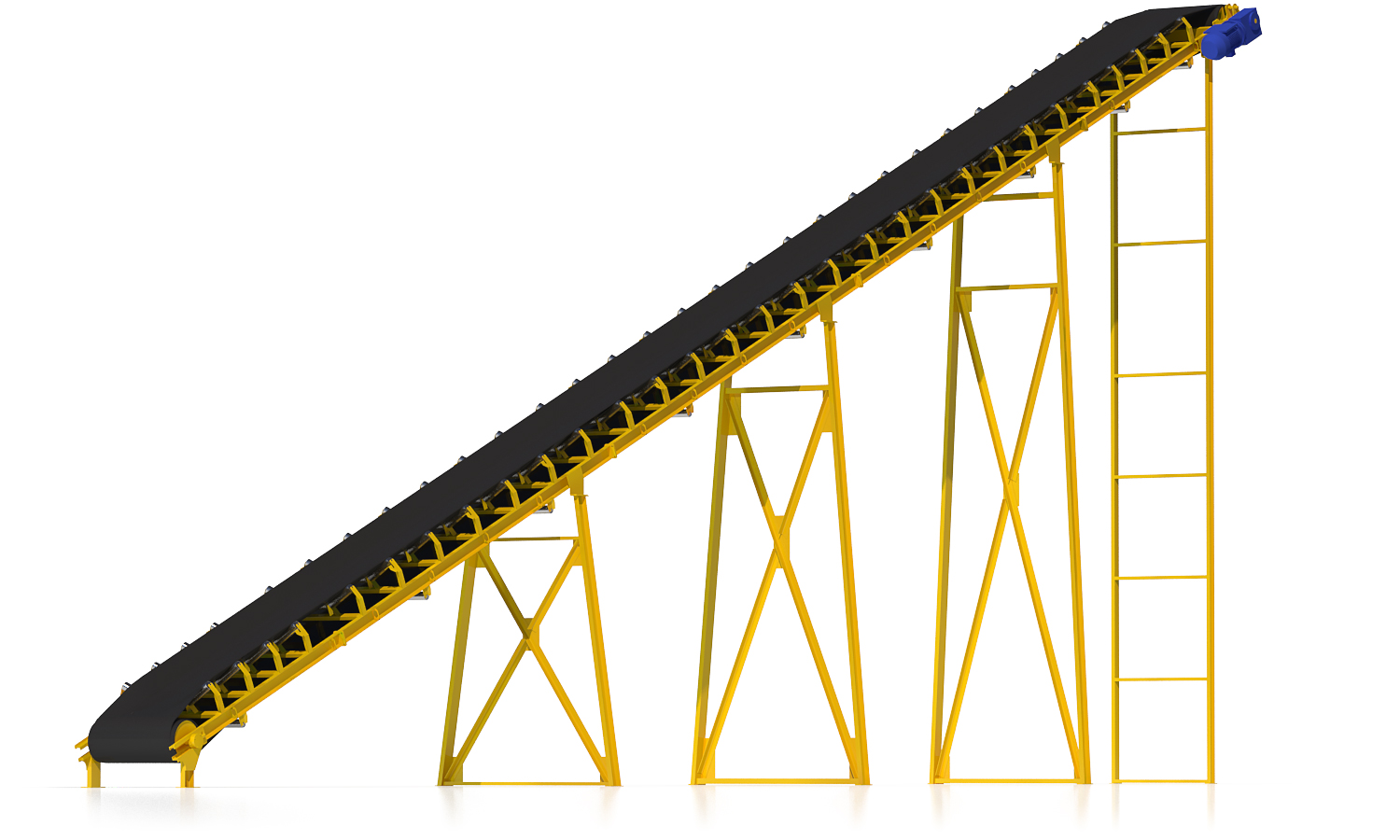

178 500

- conveyor length, mm 3,000

- The width of the conveyor belt, mm 500

- Installed power, kW 2,2

- Belt speed, m s 0,58

- Productivity, tons hour 55

- Type of tape гладкая

- conveyor installation angle, degrees 0...30

248 400

- conveyor length, mm 5,000

- The width of the conveyor belt, mm 500

- Installed power, kW 2,2

- Belt speed, m s 0,58

- Productivity, tons hour 55

- Type of tape гладкая

- conveyor installation angle, degrees 0...30

290 500

- conveyor length, mm 7000

- The width of the conveyor belt, mm 500

- Installed power, kW 4

- Belt speed, m s 0,78

- Productivity, tons hour 55

- Type of tape гладкая

- conveyor installation angle, degrees 0...30

325 200

- conveyor length, mm 8,000

- The width of the conveyor belt, mm 500

- Installed power, kW 4

- Belt speed, m s 0,58

- Productivity, tons hour 55

- Type of tape гладкая

- conveyor installation angle, degrees 0...30

459 400

- conveyor length, mm 8,000

- The width of the conveyor belt, mm 800

- Installed power, kW 7.5

- Belt speed, m s 0,9

- Productivity, tons hour 80

- Type of tape gladkaya (optional chevron)

- conveyor installation angle, degrees 0...30

5 842 500

- Capacity, cu m per hour 20...30

- single-shaft mixer БП-1Г-750С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (4 х 8) = 32

- Total power, kW 36

- Sector gate, pneumatic control

- Weight, kg 13100

417 900

- conveyor length, mm 10,000

- The width of the conveyor belt, mm 500

- Installed power, kW 4

- Belt speed, m s 0,58

- Productivity, tons hour 55

- Type of tape гладкая

- conveyor installation angle, degrees 0...30

583 500

- conveyor length, mm 10,000

- The width of the conveyor belt, mm 800

- Installed power, kW 7.5

- Belt speed, m s 0,58

- Productivity, tons hour 80

- Type of tape gladkaya (optional chevron)

- conveyor installation angle, degrees 0...30

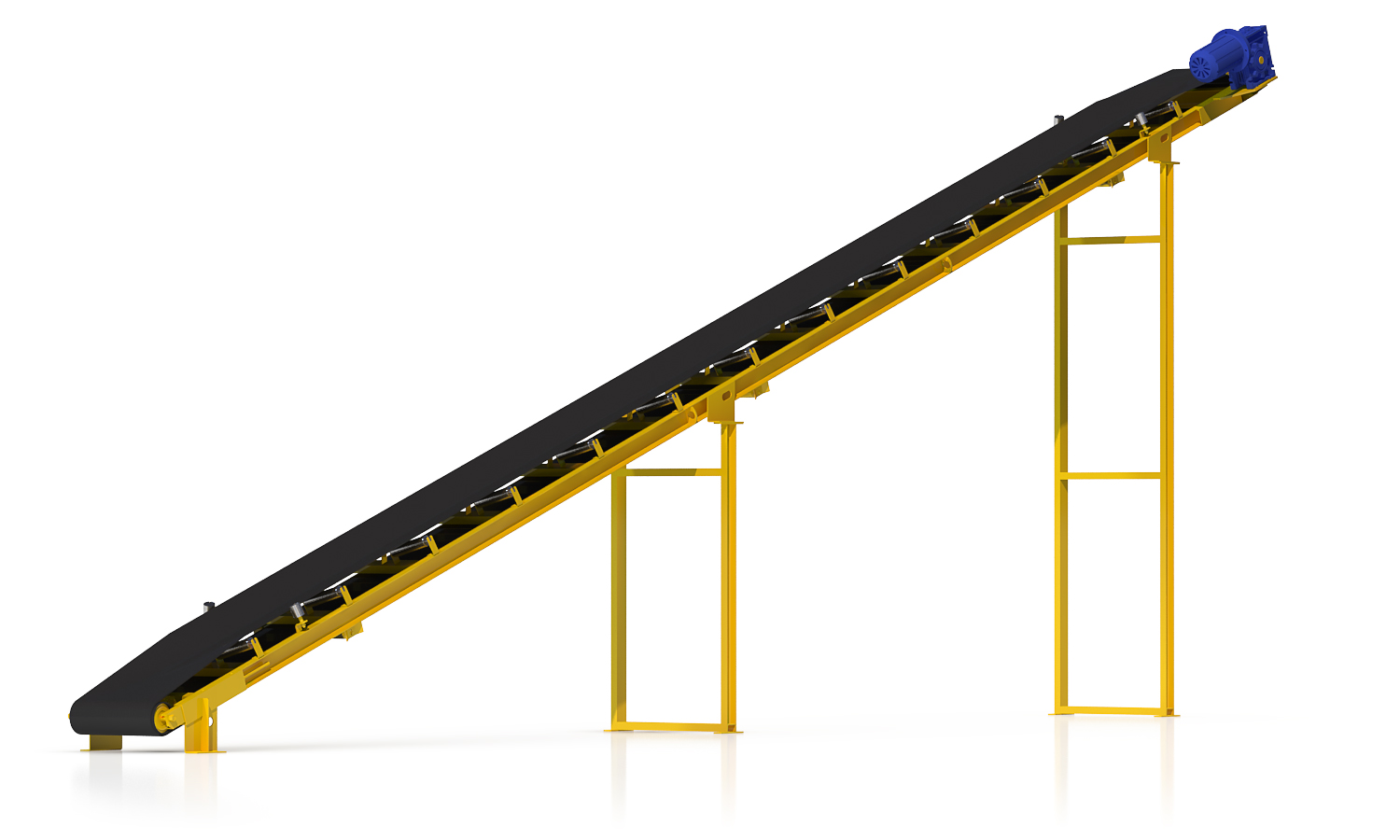

907 700

- conveyor length, mm 16,000

- The width of the conveyor belt, mm 600

- Installed power, kW 7.5

- Belt speed, m s 0,92

- Productivity, tons hour 75

- Type of tape shevronnaya

- conveyor installation angle, degrees 25

1 105 900

- conveyor length, mm 18,000

- The width of the conveyor belt, mm 800

- Installed power, kW 15

- Belt speed, m s 1,67

- Productivity, tons hour 100

- Type of tape shevronnaya

- conveyor installation angle, degrees 25

699 900

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 120...240

- Performance on a pavement slab 100h200, pieces per hour 400...800

- molding cycle s 50...90

- The number of moldings per hour piece. 40…80

- Power vibration table, kW 5.5

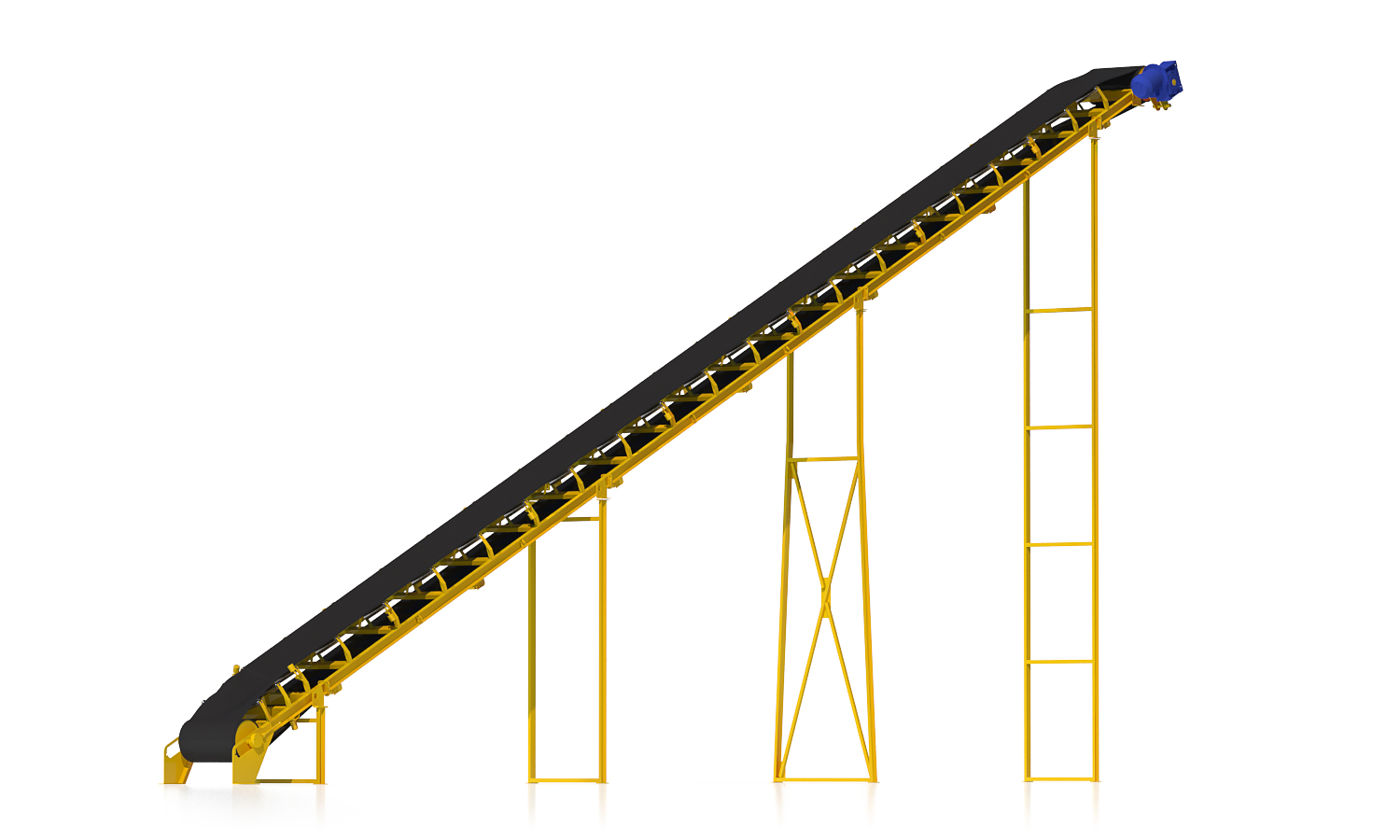

1 964 800

- conveyor length, mm 21000

- The width of the conveyor belt, mm 1,000

- Installed power, kW 18,5

- Belt speed, m s 1,67

- Productivity, tons hour 120

- Type of tape shevronnaya

- conveyor installation angle, degrees 25

1 006 000

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 132...270

- Performance paving tiles 100h200, pcs h 420...900

- molding cycle s 40...85

- Power vibration table, kW 5.5

- Total installed power, kW 9,5

1 137 800

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 135...270

- Performance paving tiles 100h200, pcs h 450...900

- molding cycle s 40...80

- The number of moldings per hour piece. 45…90

- Power vibration table, kW 5.5

1 257 800

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 216...360

- Performance paving tiles 100h200, pcs h 720...1200

- molding cycle 30...60

- The number of moldings per hour piece. 72…120

- Power vibration table, kW 5.5

1 389 500

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 216...360

- Performance paving tiles 100h200, pcs h 720...1200

- molding cycle s 30...50

- The number of moldings per hour piece. 60…120

- Power vibration table, kW 5.5

5 107 400

- Capacity, cu m per hour 20...30

- single-shaft mixer БП-1Г-750С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (2 х 8) = 16

- Total power, kW 32

- Sector gate, pneumatic control

- Height, mm 12,380

1 531 300

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 40...250

- Performance of masonry 390h190h188, pieces per hour 135...270

- Performance paving tiles 100h200, pcs h 450...900

- molding cycle s 40...80

- The number of moldings per hour piece. 45…90

- Power vibration table, kW 5.5

1 653 500

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 135...270

- Performance paving tiles 100h200, pcs h 450...900

- molding cycle s 40...80

- The number of moldings per hour piece. 45…90

- Power vibration table, kW 5.5

2 189 200

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 135...270

- Performance paving tiles 100h200, pcs h 450...900

- molding cycle s 40...80

- The number of moldings per hour piece. 45…90

- Power vibration table, kW 5.5

1 476 083

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 216...360

- Performance paving tiles 100h200, pcs h 720...1200

- molding cycle s 30...50

- The number of moldings per hour piece. 60…120

- Power vibration table, kW 5.5

1 715 250

- The size of the molding zone, mm x mm 400 x 600

- The height of the molding zone, mm 50...200

- Performance of masonry 390h190h188, pieces per hour 135...270

- Performance paving tiles 100h200, pcs h 450...900

- molding cycle s 40...80

- The number of moldings per hour piece. 45…90

- Power vibration table, kW 5.5

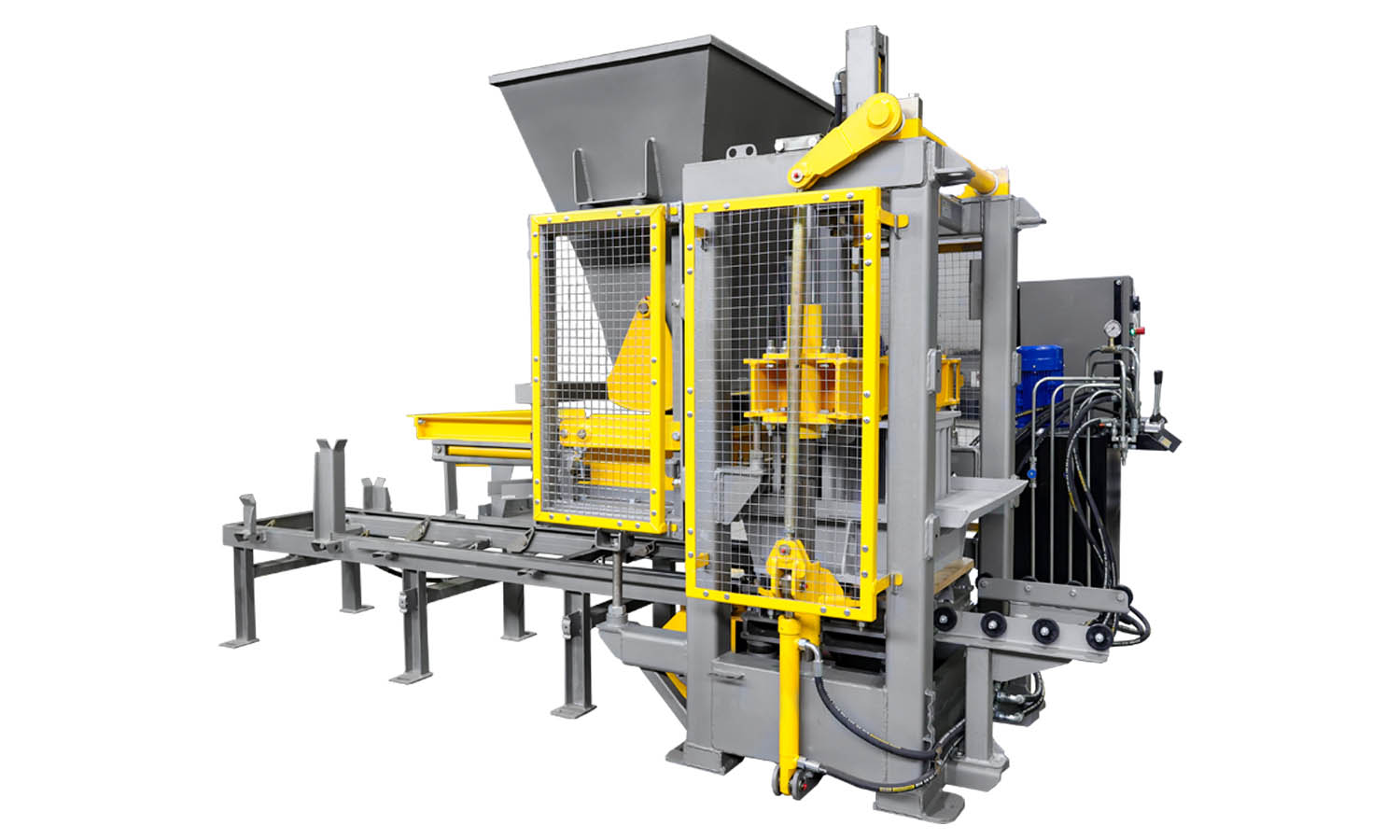

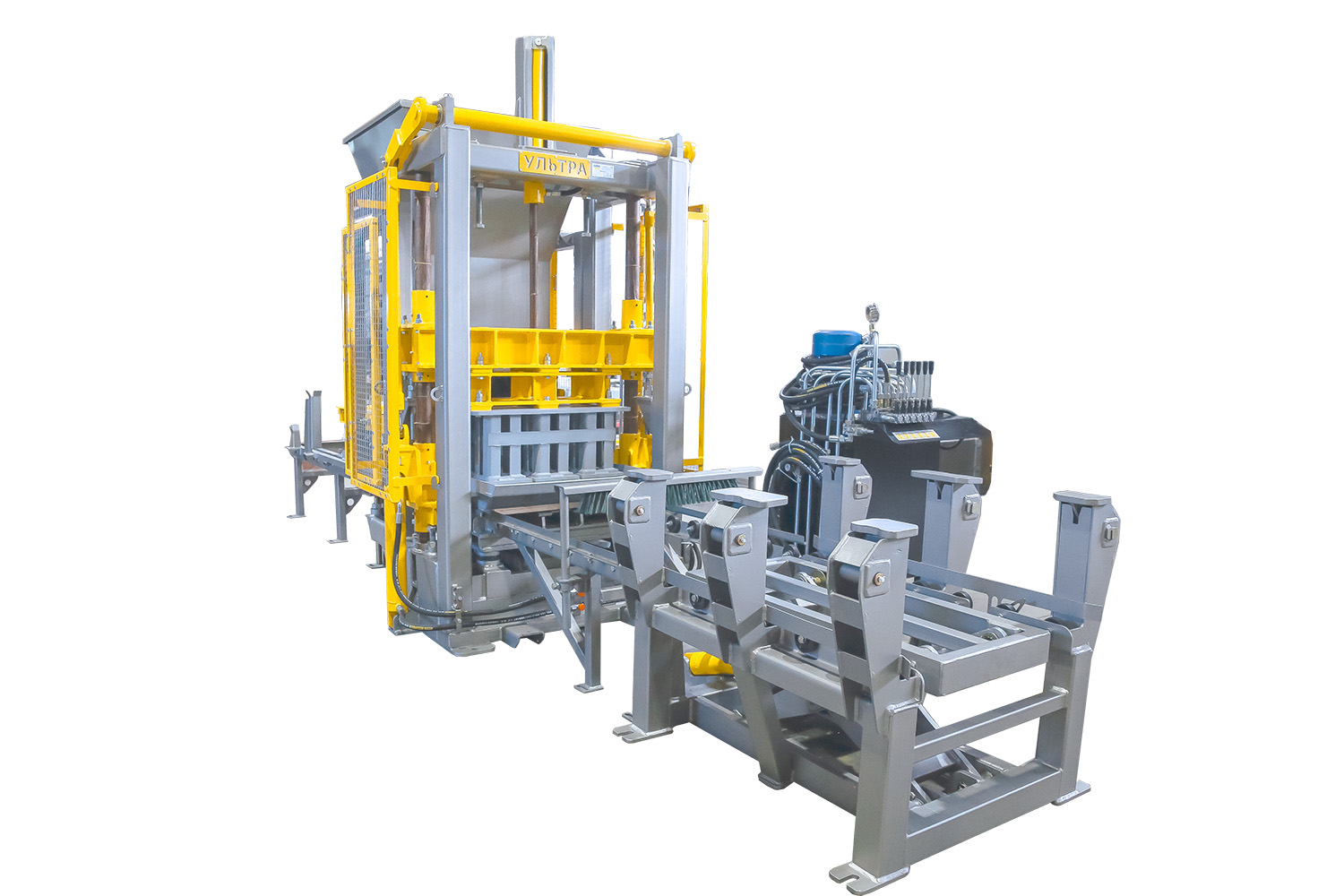

1 683 900

- Vibropress uLTRA

- LK 5-0,5 Belt Conveyor

- BP-1G-300 Concrete Mixer

- Performance of masonry 390h190h188, pieces per hour 240

- Performance paving tiles 100h200, pcs h 800

- Power vibration table, kW 5.5

- Total installed power, kW 17,5

2 452 000

- Vibropress uLTRA

- BP-2G-375s Twin-shaft concrete mixer

- Elevated structure

- Performance of masonry 390h190h188, pieces per hour 240

- Performance paving tiles 100h200, pcs h 800

- Power vibration table, kW 5.5

- Total installed power, kW 21,5

2 549 600

- Vibropress uLTRA

- BP-2G-375s Twin-shaft concrete mixer

- LK 5-0,5 Belt Conveyor

- Performance of masonry 390h190h188, pieces per hour 240

- Performance paving tiles 100h200, pcs h 800

- Power vibration table, kW 5.5

- Total installed power, kW 23,7

4 301 300

- Vibropress uLTRA

- MOBIL-20 Concrete Plant

- LK 5-0,5 Belt Conveyor

- Performance of masonry 390h190h188, pieces per hour 240

- Performance paving tiles 100h200, pcs h 800

- Power vibration table, kW 5.5

- Total installed power, kW 38,7

4 326 800

- Vibropress uLTRA

- Concrete plant COMPACT 20

- Performance of masonry 390h190h188, pieces per hour 240

- Performance paving tiles 100h200, pcs h 800

- Power vibration table, kW 5.5

- Total installed power, kW 37

5 539 800

- Capacity, cu m per hour 15...30

- single-shaft mixer БП-1Г-750С

- Automatic operating mode по принципу "одна кнопка"

- Рабочий объем бункеров, м³ (3 х 8) = 24

- Total power, kW 32

- Sector gate, pneumatic control

- Length, mm 15270

2 118 900

- The size of the molding zone, mm x mm 400 x 1000

- The height of the molding zone, mm 120...200

- Power vibration table, kW 2,2

- Installed power, kW 9,2

- The frequency of the vibrating table fluctuations, Hz 60

- Hopper capacity, cu. m. 0,9

- the molding cycle time, s 30…60

2 352 700

- The size of the molding zone, mm x mm 400 x 1000

- The height of the molding zone, mm 120...200

- Power vibration table, kW 2,2

- Installed power, kW 9,2

- The frequency of the vibrating table fluctuations, Hz 60

- Hopper capacity, cu. m. 0,9

- the molding cycle time, s 30…60

2 784 000

- The size of the molding zone, mm x mm 400 x 1000

- The height of the molding zone, mm 50...200

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 13

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

3 002 200

- The size of the molding zone, mm x mm 400 x 1000

- The height of the molding zone, mm 50...200

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 13

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

3 305 200

- The size of the molding zone, mm x mm 400 x 1000

- The height of the molding zone, mm 50...200

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 13

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

3 203 700

- The size of the molding zone, mm x mm 400 x 1000

- The height of the molding zone, mm 50...200

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 13

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

3 901 700

- STANDART Block Making Machine

- BP-2G-375s Twin-shaft concrete mixer

- Elevated structure

- Power vibration table, kW 7.5

- Installed power, kW 25

- Performance of masonry 390h190h188, pieces per hour 500

- Performance paving tiles 100h200, pcs h 1800

4 039 400

- STANDART Block Making Machine

- BP-2G-375s Twin-shaft concrete mixer

- LK 5-0,5 Belt Conveyor

- Power vibration table, kW 7.5

- Installed power, kW 27,2

- Performance of masonry 390h190h188, pieces per hour 500

- Performance paving tiles 100h200, pcs h 1800

5 791 100

- STANDART Block Making Machine

- MOBIL-20 Concrete Plant

- LK 5-0,5 Belt Conveyor

- Power vibration table, kW 7.5

- Installed power, kW 42,2

- Performance of masonry 390h190h188, pieces per hour 500

- Performance paving tiles 100h200, pcs h 1800

5 776 800

- STANDART Block Making Machine

- Concrete plant COMPACT 20

- Power vibration table, kW 7.5

- Installed power, kW 42,2

- Performance of masonry 390h190h188, pieces per hour 500

- Performance paving tiles 100h200, pcs h 1800

5 896 000

- Capacity, cu m per hour 20...30

- single-shaft mixer БП-1Г-750С

- Automatic operating mode по принципу "одна кнопка"

- Volume of bunkers, m³ (4 х 8) = 32

- Total power, kW 36

- Sector gate, pneumatic control

- Length, mm 18200

3 375 400

- The size of the molding zone, mm x mm 1000 x 600

- The height of the molding zone, mm 50...300

- molding cycle s 30...80

- Power vibration table, kW 11

- Total installed power, kW 16,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

3 888 200

- The size of the molding zone, mm x mm 1000 x 600

- The height of the molding zone, mm 50...300

- molding cycle s 30...80

- Power vibration table, kW 11

- Total installed power, kW 16,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

4 233 500

- The size of the molding zone, mm x mm 1000 x 600

- The height of the molding zone, mm 50...300

- molding cycle s 30...80

- Power vibration table, kW 11

- Installed power, kW 16,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

4 043 900

- The size of the molding zone, mm x mm 1000 x 600

- The height of the molding zone, mm 50...300

- molding cycle s 30...80

- Power vibration table, kW 11

- Total installed power, kW 16,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

1 565 417

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

1 678 417

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

1 732 167

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

1 952 600

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

2 209 200

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 12,6

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

2 100 500

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

2 357 000

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

2 137 083

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

2 369 500

- The size of the molding zone, mm x mm 800 x 400

- The height of the molding zone, mm 50...250

- molding cycle s 30...80

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

2 503 100

- Vibropress Optimal 2.0

- BP-1G-300 Concrete Mixer

- Belt conveyor LK 6-0.5

- Power vibration table, kW 7.5

- Installed power, kW 11,5

- Performance of masonry 390h190h188, pieces per hour 400

- Performance paving tiles 100h200, pcs h 1400

3 135 200

- Vibropress Optimal 2.0

- Concrete plant Mini RBU-10

- Power vibration table, kW 7.5

- Installed power, kW 21,5

- Performance of masonry 390h190h188, pieces per hour 400

- Performance paving tiles 100h200, pcs h 1400

- Length, mm

3 132 900

- Vibropress Optimal

- BP-1G-300 Concrete Mixer

- BP-1G-100 Concrete Mixer

- Power vibration table, kW 7.5

- Installed power, kW 23,6

- Performance of masonry 390h190h188, pieces per hour 400

- Performance paving tiles 100h200, pcs h 1400

8 969 800

- The size of the molding zone, mm x mm 1000 x 600

- The height of the molding zone, mm 50...300

- molding cycle s 30-60

- Power vibration table, kW 11

- Total installed power, kW 36

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

9 040 300

- The size of the molding zone, mm x mm 1000 x 600

- The height of the molding zone, mm 50...300

- molding cycle s 30-60

- Power vibration table, kW 11

- Total installed power, kW 36

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

12 881 500

- The size of the molding zone, mm x mm 1000 x 600

- The height of the molding zone, mm 50...300

- molding cycle s 30-60

- Power vibration table, kW 11

- Total installed power, kW 36

- The frequency of the vibrating table fluctuations, Hz 45...85

- Hydraulic pressure, MPa 6...12

4 950 900

- The size of the molding zone, mm x mm 1000 x 600

- BP-2G-375s Twin-shaft concrete mixer

- Belt conveyor LC 7-0.5

- Power vibration table, kW 11

- Total installed power, kW 30,7

- Performance of masonry 390h190h188, pieces per hour 540

- Performance paving tiles 100h200, pcs h 2,200

5 088 700

- The size of the molding zone, mm x mm 1000 x 600

- BP-2G-375s Twin-shaft concrete mixer

- Belt conveyor LC 7-0.5

- Power vibration table, kW 11

- Total installed power, kW 30,7

- Performance of masonry 390h190h188, pieces per hour 540

- Performance paving tiles 100h200, pcs h 2,200

6 840 300

- Vibropress MAXIMAL 2.0

- MOBIL-20 Concrete Plant

- Belt conveyor LC 7-0.5

- Power vibration table, kW 11

- Total installed power, kW 45,7

- Performance of masonry 390h190h188, pieces per hour 540

- Performance paving tiles 100h200, pcs h 2,200

6 826 000

- Vibropress MAXIMAL 2.0

- Concrete plant COMPACT 20

- Power vibration table, kW 11

- Total installed power, kW 45,7

- Performance of masonry 390h190h188, pieces per hour 540

- Performance paving tiles 100h200, pcs h 2,200

3 913 700

- The size of the molding zone, mm x mm 2380 x 600

- The height of the molding zone, mm 580

- Power vibrators kW 5.5

- Total installed power, kW 17,4

- Hydraulic pressure, MPa 8...12

- The duration of a complete cycle, 180

- The number of moldings per hour piece. 20

4 031 200

- The size of the molding zone, mm x mm 2380 x 600

- The height of the molding zone, mm 580

- Power vibrators kW 5.5

- Total installed power, kW 17,4

- Hydraulic pressure, MPa 8...12

- The duration of a complete cycle, 180

- The number of moldings per hour piece. 20

2 747 200

- The size of the molding zone, mm x mm 2500 x 600

- The height of the molding zone, mm 580

- Power vibrators kW 5.5

- Total installed power, kW 17,4

- Hydraulic pressure, MPa 8...12

- The duration of a complete cycle, 200

- The number of moldings per hour piece. 15

5 001 500

- The size of the molding zone, mm x mm 2380 x 1600

- The height of the molding zone, mm 280...300

- Vibrator power, kW 5.5

- Total installed power, kW 17,4

- Hydraulic pressure, MPa 8...12

- The number of moldings per hour piece. 6...12

- The duration of a complete cycle, 300

383 100

- The highest limit of the cement dosing (NAP), kg 75

- The highest limit of the water metering (NAP), kg 40

- The greatest limit of dispensing chemical additives (NAP), kg 5

- Dosing accuracy% ±1

- Maximum discharge time, sec 10

- The pressure in the pneumatic system, MPa no less 0,6

- Product particle size, mm max 2

476 000

- The highest limit of the cement dosing (NAP), kg 150

- The highest limit of the water metering (NAP), kg 75

- The greatest limit of dispensing chemical additives (NAP), kg 10

- Dosing accuracy% ±1

- Maximum discharge time, sec 10

- The pressure in the pneumatic system, MPa no less 0,6

- Product particle size, mm max 2

582 000

- The highest limit of the cement dosing (NAP), kg 300

- The highest limit of the water metering (NAP), kg 150

- The greatest limit of dispensing chemical additives (NAP), kg 20

- Dosing accuracy% ±1

- Maximum discharge time, sec 10

- The pressure in the pneumatic system, MPa no less 0,6

- Product particle size, mm max 2

582 000

- The highest limit of the cement dosing (NAP), kg 16 149

- The highest limit of the water metering (NAP), kg 180

- The greatest limit of dispensing chemical additives (NAP), kg 2x25

- Dosing accuracy% ±1

- Maximum discharge time, sec 10

- The pressure in the pneumatic system, MPa no less 0,6

- Product particle size, mm max 2

54 900

54 900

103 500

93 750

275 800

344 800

344 800

686 200

- The highest limit of the cement dosing (NAP), kg 500

- The highest limit of the water metering (NAP), kg 250

- The greatest limit of dispensing chemical additives (NAP), kg 30 (2х30)

- Dosing accuracy% ±1

- Maximum discharge time, sec 23

- The pressure in the pneumatic system, MPa no less 0,6

- Product particle size, mm max 2

757 700

- The highest limit of the cement dosing (NAP), kg 600

- The highest limit of the water metering (NAP), kg 300

- The greatest limit of dispensing chemical additives (NAP), kg 40

- Dosing accuracy% ±1

- Maximum discharge time, sec 20

- The pressure in the pneumatic system, MPa no less 0,6

- Product particle size, mm max 2

951 000

- The highest limit of the cement dosing (NAP), kg 900

- The highest limit of the water metering (NAP), kg 450

- The greatest limit of dispensing chemical additives (NAP), kg 60

- Dosing accuracy% ±1

- Maximum discharge time, sec 20

- The pressure in the pneumatic system, MPa no less 0,6

- Product particle size, mm max 2

1 152 200

- The highest limit of the cement dosing (NAP), kg 1,200

- The highest limit of the water metering (NAP), kg 550

- The greatest limit of dispensing chemical additives (NAP), kg 70

- Dosing accuracy% ±1

- Maximum discharge time, sec 20

- The pressure in the pneumatic system, MPa no less 0,6

- Product particle size, mm max 2

603 400

- Maximum dosing limit for fibers with a bulk density of 123 kg/m³, no more than, kg 8

- Dosing accuracy% ±1

- Productivity, kg/min 1.5 (depending on fiber type)

- Fiber length, no more than, mm 30

- Installed power, kW 0,54

- Length, mm 800(1150)

- Width, mm 800

345 300

- The highest limit of the cement dosing (NAP), kg 300

- Dosing accuracy% ±1

- Maximum discharge time, sec 10

- The pressure in the pneumatic system, MPa no less 0,6

- Product particle size, mm max 2

- Length, mm High capacity silos

- Width, mm 905

295 900

- The capacity of the chamber, m³ 0.07

- Capacity, cbm h 1,2

- type of product cement, sypuchyeye

- The maximum dosing time, with unlimited

- Power Supply, 380

- Installed power, kW 0,75

- The drive gear motor

122 700

- The largest dosing limit, l 1,000

- type of product water

- The amount dosed components 1

- The minimum dose, l 1

- Temperature the product, + 5...+ 90

- Dosing accuracy% ±1

- Nominal bore pipe diameter DN 25

132 300

- type of product water

- The amount dosed components 1

- The minimum dose, l 1

- Temperature the product, + 5...+ 90

- Dosing accuracy% ±1

- Nominal bore pipe diameter DN 50

- Nominal flow, m³/h 15

47 600

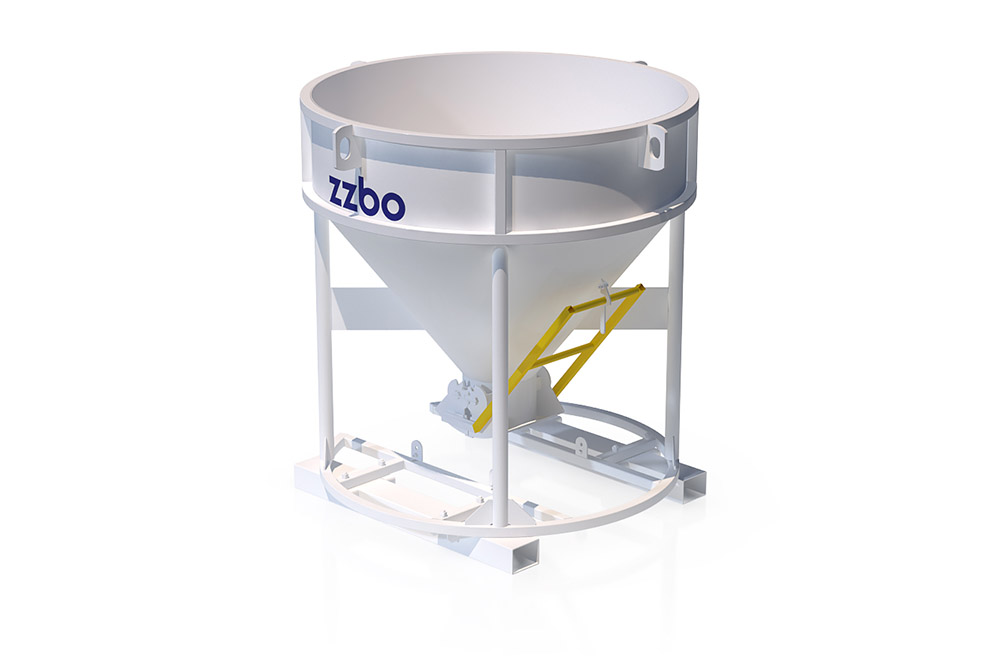

- Volume, cu. m. 1

- Carrying capacity, t 2,5

- Weight, kg. 260

- Type of closure manual, two-sector

1 100

1 675

81 500

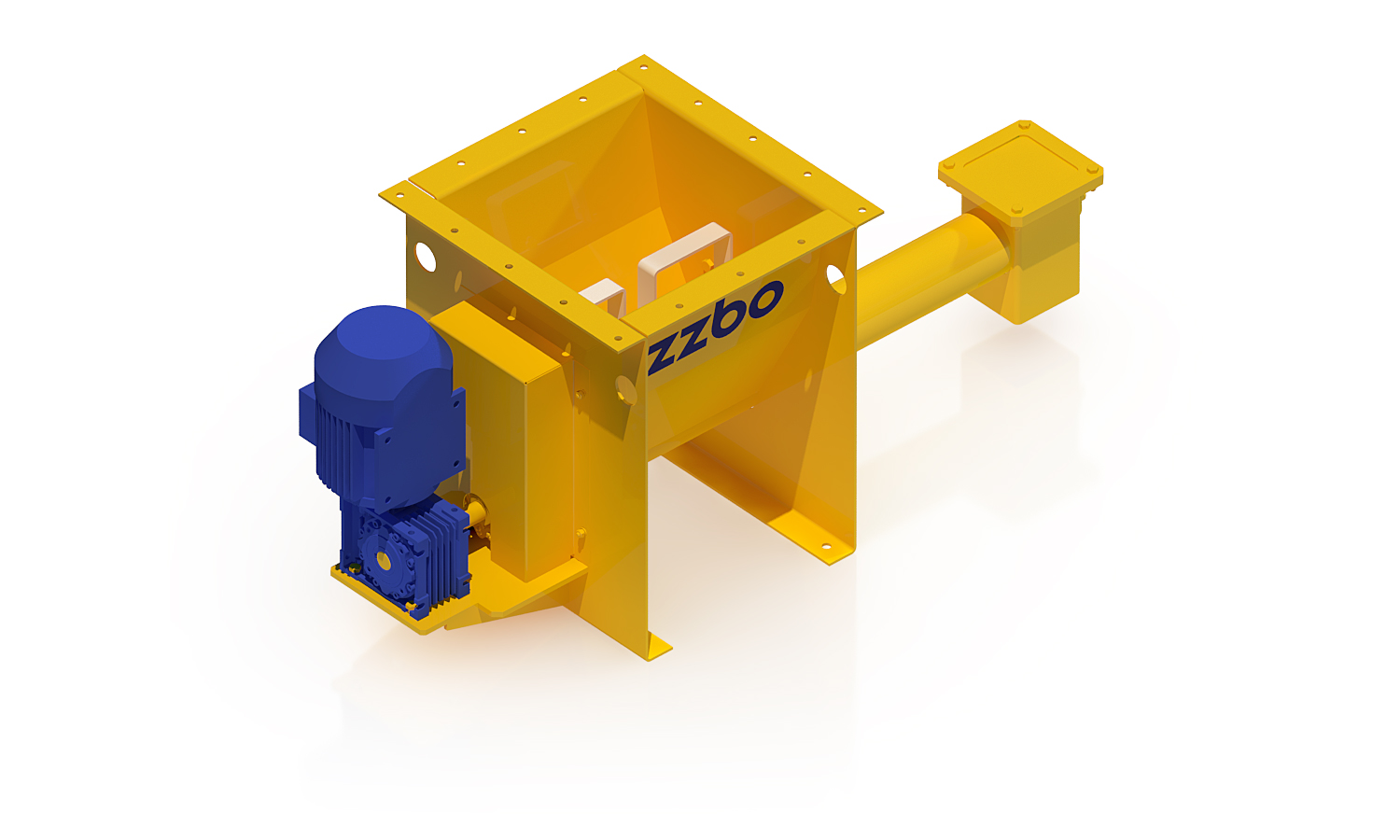

- Capacity rastarivatelâ, tons 2,35

- The volume of the cube. m 1,57

- Email download thaw (optional)

- MVE300 Vibrator, kW (optional) 00.3

- Banks thickness, mm 3

- Productivity, tons hour 40

- Free falling system optional

83 000

- Capacity rastarivatelâ, tons 2,2

- The volume of the cube. m 1,5

- Email download thaw (optional)

- MVE300 Vibrator, kW (optional) 00.3

- Banks thickness, mm 3

- Productivity, tons hour 40

- Free falling system optional

91 000

- Capacity rastarivatelâ, tons 2,35

- The volume of the cube. m 1,57

- Email download thaw (optional)

- MVE300 Vibrator, kW (optional) 00.3

- Banks thickness, mm 3

- Productivity, tons hour 40

- Free falling system optional

132 400

- Capacity rastarivatelâ, tons 2,35

- The volume of the cube. m 1,57

- Email download thaw (optional)

- MVE300 Vibrator, kW (optional) 00.3

- Banks thickness, mm 3

- Productivity, tons hour 40

- Free falling system optional

163 400

- Weight, kg 2,000

- The volume of the cube. m 0,56

- Email download thaw (optional)

- Vibrator MVE300, KW 00.3

- Banks thickness, mm 3

- Productivity, tons hour 40

- Free falling system there is

233 000

- Capacity rastarivatelâ, tons 6

- The volume of the cube. m 4

- Banks thickness, mm 3

- Weight, kg 980

- Height, mm 3525

- Width, mm 2440

- Tank diameter, mm Maximum productivity of the belt feeder, t/h

24 300

- Производительность, м³/ч 27

- power, kWt 1,5

- Head, m 13.9

- Weight, kg 38

35 700

- Производительность, м³/ч 48

- power, kWt 3

- Head, m 17

- Weight, kg 51

49 000

- Производительность, м³/ч 72

- power, kWt 7.5

- Head, m 24.5

- Weight, kg 73

49 000

- Производительность, м³/ч 90

- power, kWt 7.5

- Head, m 23

- Weight, kg 74

314 100

- Weight, kg 2,000

- The volume of the cube. m 0,56

- Loading manual mechanical hoist (integrated valve)

- Vibrator MVE300, KW 00.3

- Banks thickness, mm 3

- Productivity, tons hour 40

- Free falling system there is

688 700

- Weight, kg 2,000

- The volume of the cube. m 0,56

- Download e-mail. hoist (integrated valve)

- Capacity of electric hoists, KW 3

- Vibrator MVE300, KW 00.3

- Banks thickness, mm 3

- Productivity, tons hour 40

116 400

- housing material stainless steel

- Number of print cartridges, NY 3

- Productivity, m3 h 1600

- The area of the filter surface, m2 18,8

- Weight, kg 85

- cleaning system Пневматическая

146 800

- housing material stainless steel

- Number of print cartridges, NY 4

- Productivity, m3 h 2136

- The area of the filter surface, m2 25,1

- Weight, kg 100

- cleaning system Вибрационная

130 800

- housing material stainless steel

- Number of print cartridges, NY 4

- Productivity, m3 h 2136

- The area of the filter surface, m2 25,1

- Weight, kg 100

- cleaning system Пневматическая

19 500

- Weight, kg 12,7

- Dimensions in mm 428x428x310

10 300

- The noise level in an open area, dB 0

- Voltage 220V

- Power consumption of the motor 4 BATT

- Shaft speed, rev / min 1.5

- Maximum operating temperature, C +80

- The minimum working temperature, C -20

17 100

- Dimensions in mm 440х405х76

- Weight, kg 13

- Material Алюминиевый сплав

11 400

- type vibrator Electric ploshchadochnyj

- Мощность эл/двигателя, кВт 0.27

- Вынуждающая сила, кг 321

- Частота колебаний, об./мин 3,000

- Overall dimensions, mm) 255х155х175

- Mounting dimensions (mm) 90h125

- Диаметр отверстий для болтов, мм 11

64 300

- housing material steel

- Number of print cartridges, NY 9

- Productivity, m3 h 565...1365

- The area of the filter surface, m2 14

- Weight, kg 82

- Voltage, V 380

- power, kWt 1,5

68 800

- housing material stainless steel

- Number of print cartridges, NY 9

- Производительность, м³\час 565…1356

- Площадь фильтрующей поверхности, м² 14

- Voltage, V 380

- power, kWt 1,5

- Weight, kg 84

79 000

- housing material stainless steel

- Number of print cartridges, NY 14

- Производительность, м³\час 1100...2200

- Площадь фильтрующей поверхности, м² 24

- Weight, kg 98

- Voltage, V 380

- power, kWt 1,5

9 600

- Диапазон регулирования положительного давления Н2О, мм 280...1000

- Диапазон регулирования отрицательного давления Н2О, мм -20...-120

- Пропускная способность, м3/ч до 13 000

- Weight, kg 9,5

11 800

- Диапазон регулирования положительного давления Н2О, мм 280...1000

- Диапазон регулирования отрицательного давления Н2О, мм -20...-120

- Пропускная способность, м3/ч до 13 000

- Weight, kg 9,5

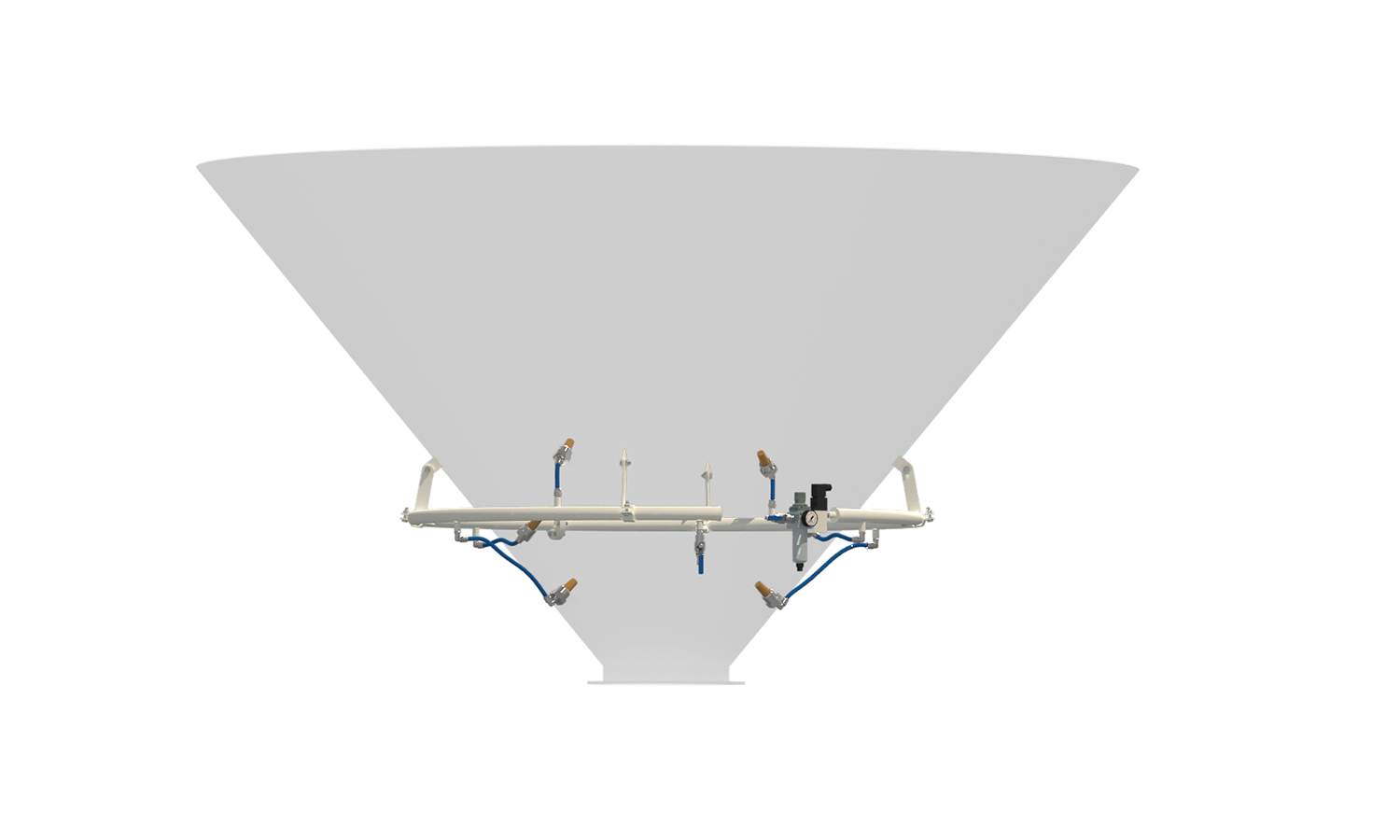

25 320

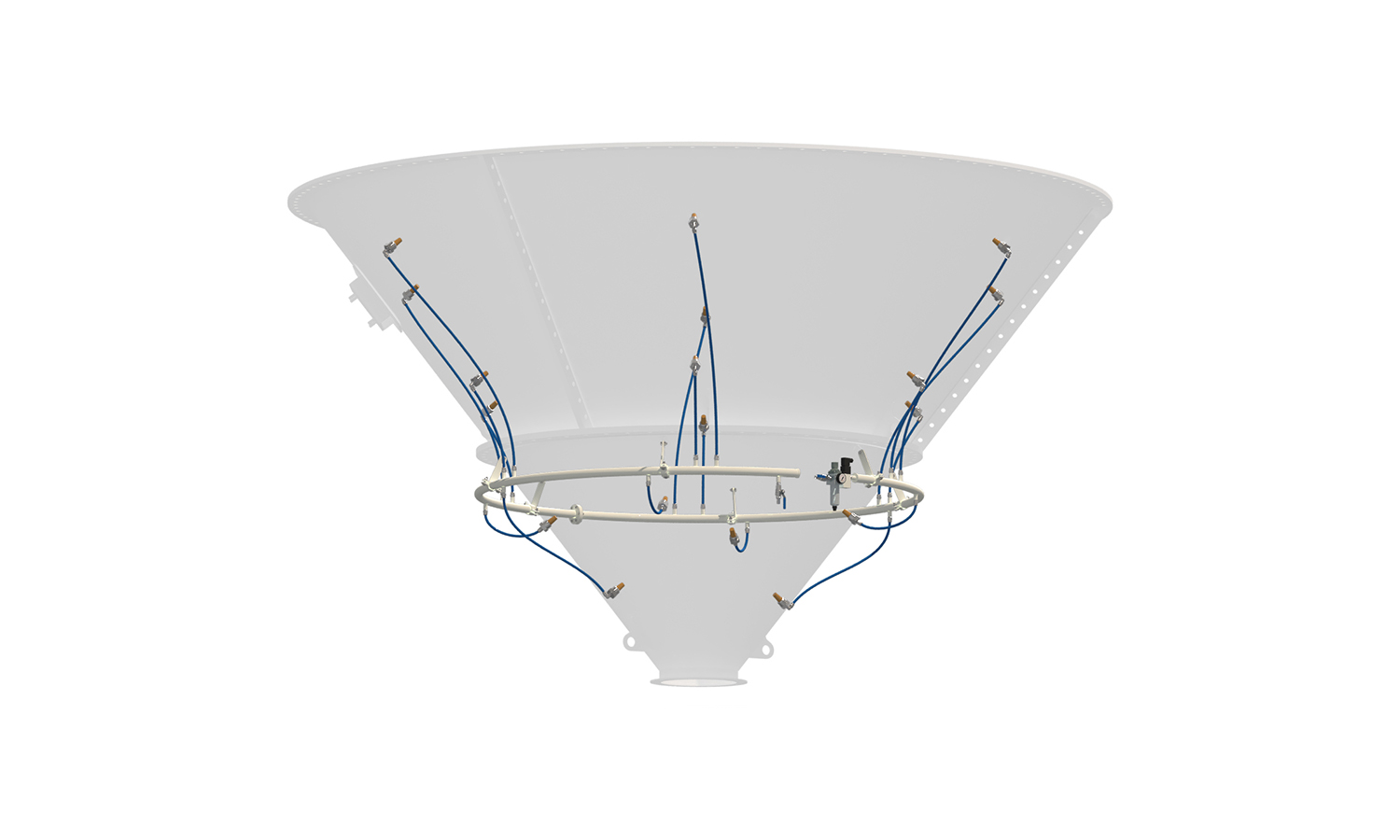

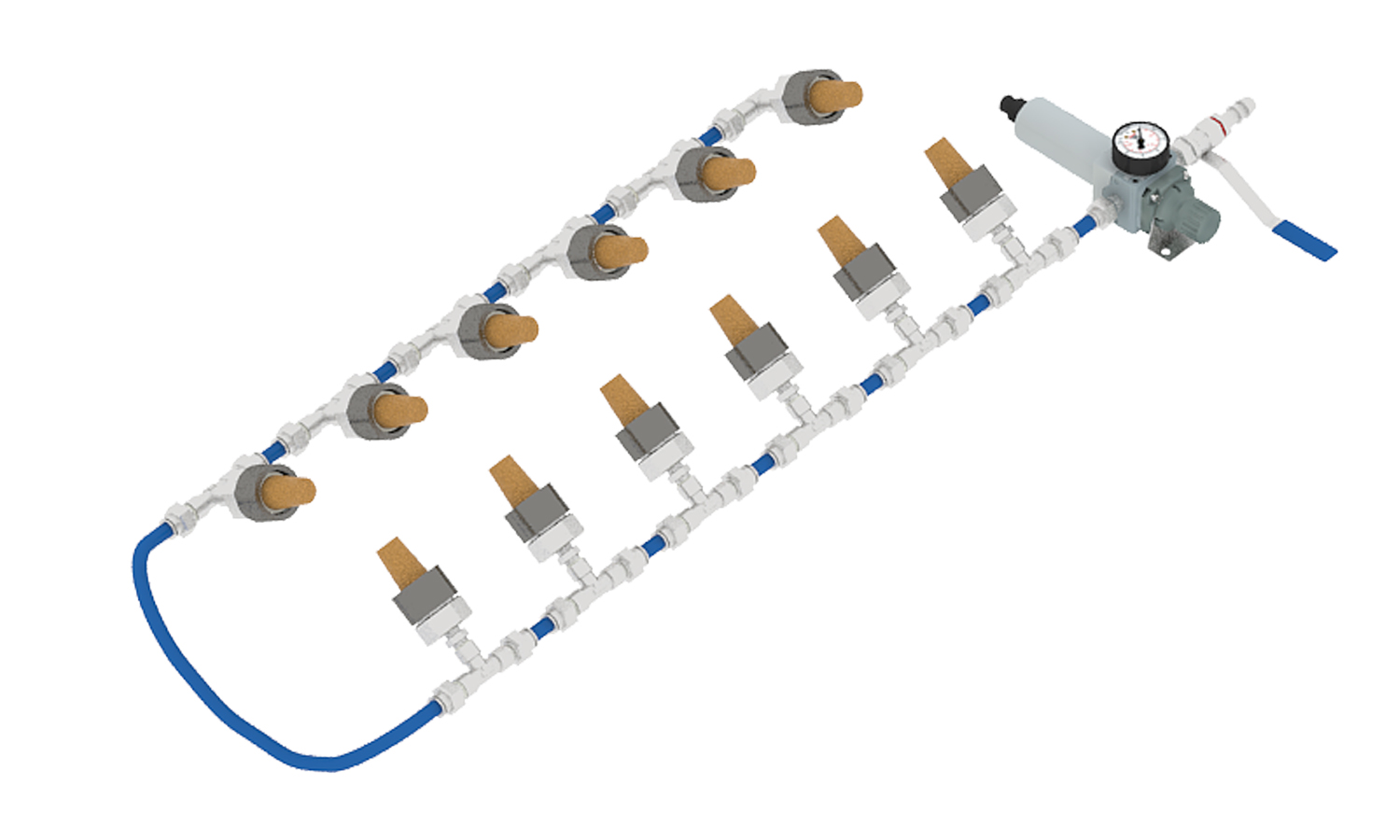

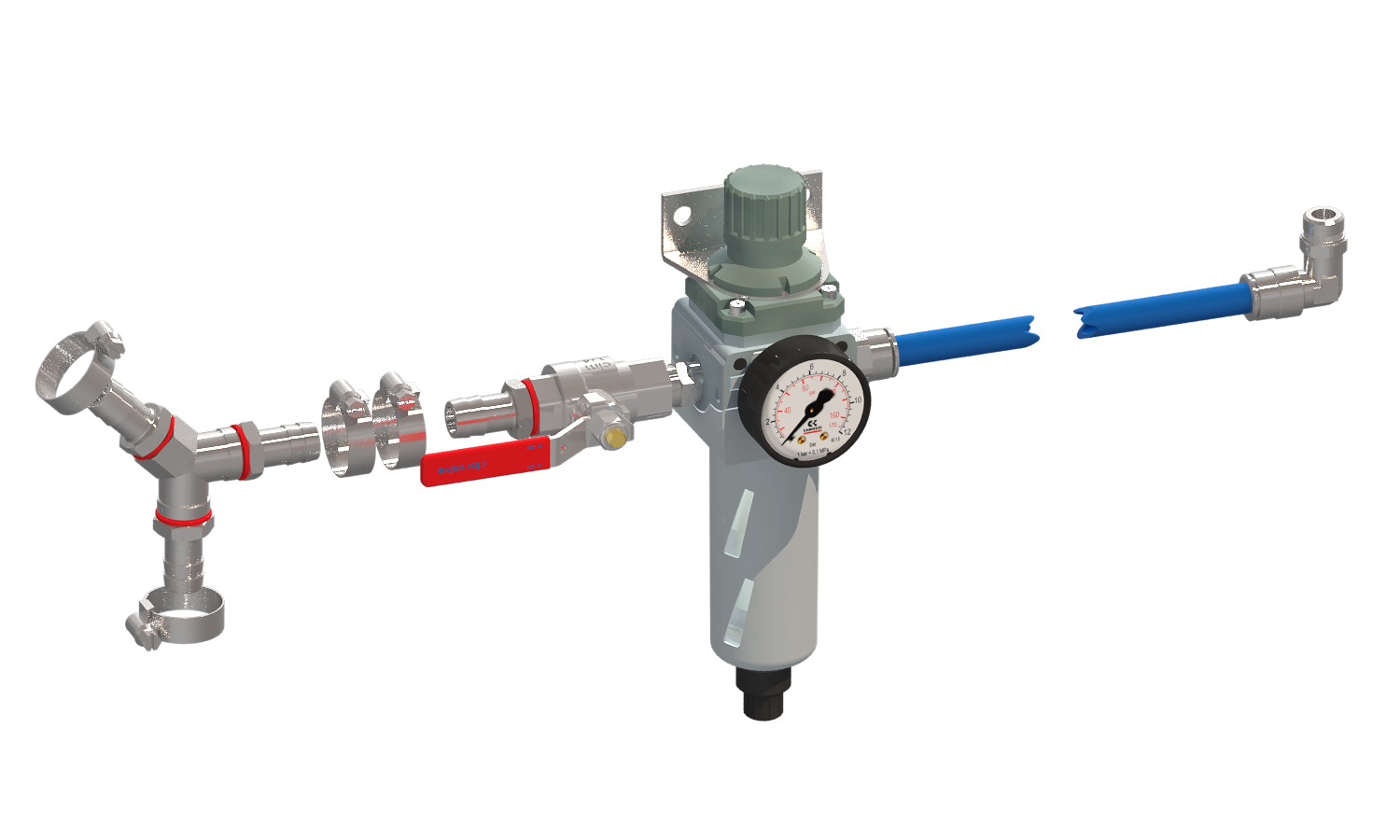

- Operating pressure, Bar 0,5

- Weight, kg 2

- Расход воздуха, м³\ч 0,4

- Number of nozzles, pcs 6

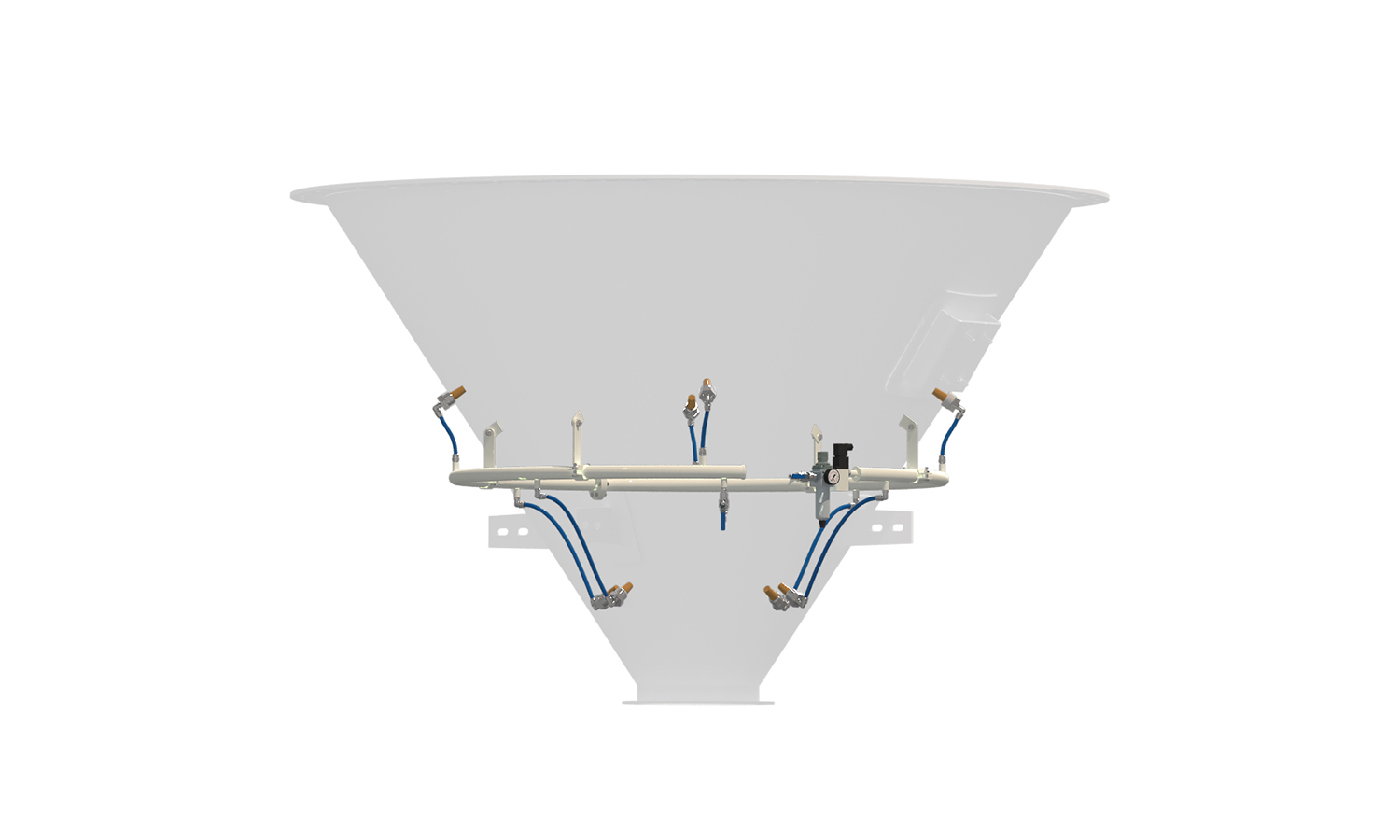

28 260

- Operating pressure, Bar 0,5

- Weight, kg 2

- Расход воздуха, м³\ч 0,4

- Number of nozzles, pcs 8

40 020

- Operating pressure, Bar 0,5

- Weight, kg 2

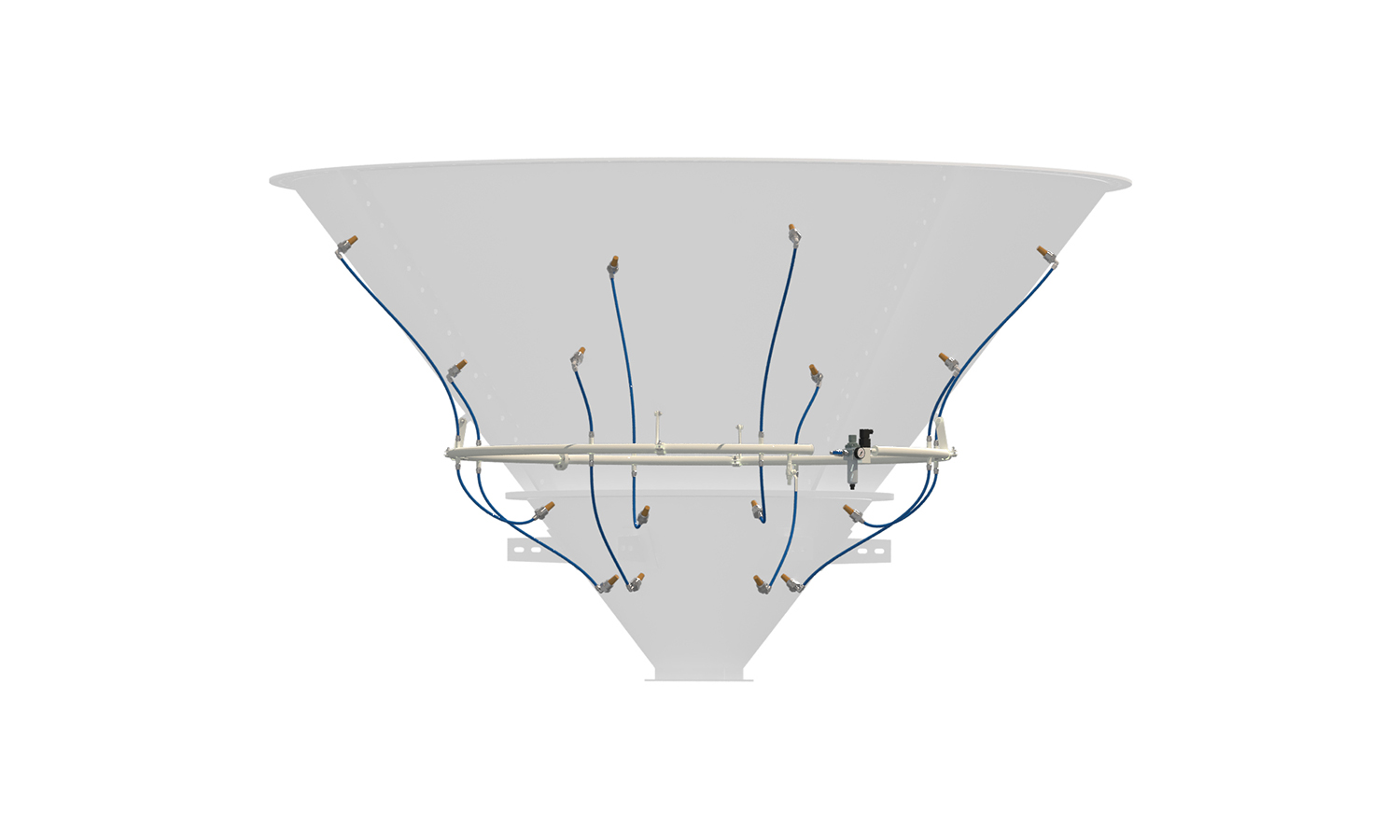

- Расход воздуха, м³\ч 0,4

- Number of nozzles, pcs 16

43 230

- Operating pressure, Bar 0,5

- Weight, kg 2

- Расход воздуха, м³\ч 0,4

- Number of nozzles, pcs 18

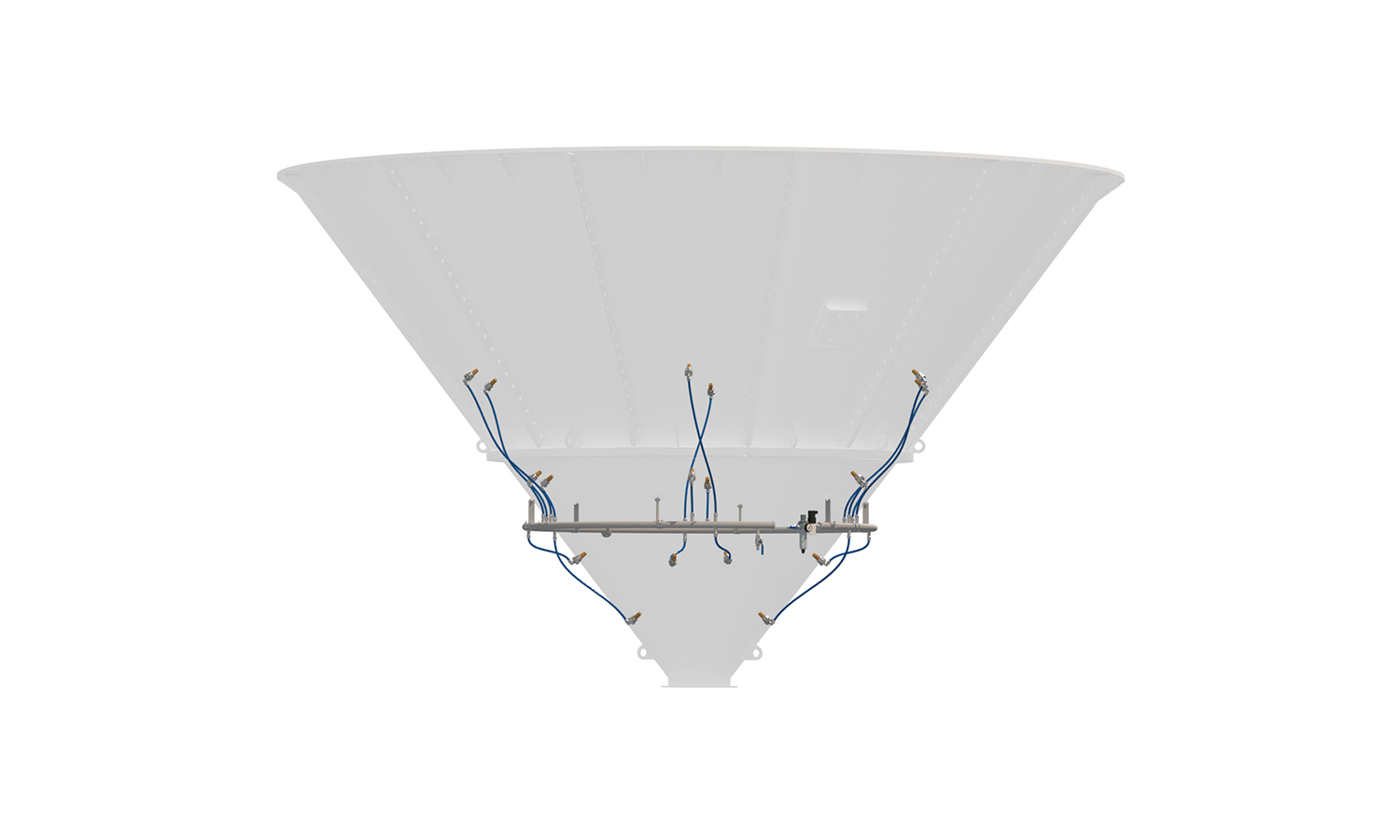

43 390

- Operating pressure, Bar 0,5

- Weight, kg 2

- Расход воздуха, м³\ч 0,4

- Number of nozzles, pcs 18

45 080

- Operating pressure, Bar 0,5

- Weight, kg 2

- Расход воздуха, м³\ч 0,4

- Number of nozzles, pcs 19

30 360

- Operating pressure, Bar 0,5

- Weight, kg 2

- Расход воздуха, м³\ч 0,4

- Number of nozzles, pcs 12

1 200

- Weight, kg 0,1

- Length, mm 65

- Давление, бар 0...0,5

4 970

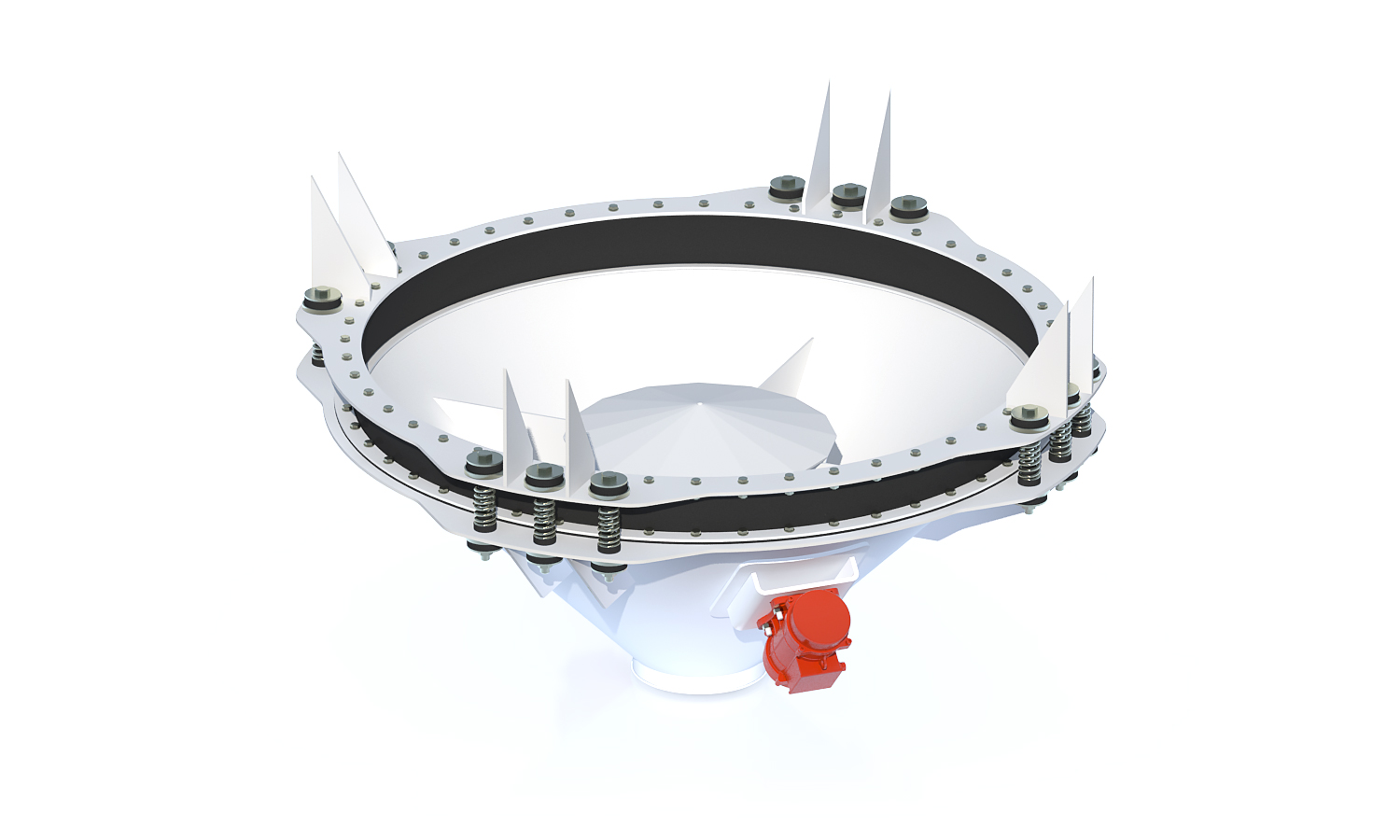

200 850

- Диаметр присоединительного кольца, мм 1,500

- Диаметр разгрузочного отверстия, мм 290

- Угол дефлектора, градусов 15

- Количество амортизаторов, шт. 12

- Material steel 09G2S

- Габариты, ДхШхВ, мм 1800х1800х850

- Weight, kg 220

109 100

- Размер, дюйм 10,1

- Разрешение экрана, px 1920×1200

- A type сенсорный IPS-экран

- Wi-Fi 802.11a/b/g/n/ac

- Диапазон сети Wi-Fi, ГГц 2,4 и 5