Concrete plant KOMPAKT-25

3 463 000

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

- BP-2G-375 Twin-Shaft Concrete Mixer

- Skip (bucket) to load the mixture

- Winch for skip lifting with electric brake

- Пневмозатвор "Camozzi" (Италия)

- Connection set for pneumatic equipment

- Changeable armour, flake type. Material – wear-resistant cast iron 12 mm thick

- Спицы усиленные (стальное литье) крепление типа "кулак"

- Changeable blades. Material: ЧХ16Н2Т cast iron (chromic high alloy wear-resistant)

- Water equilibrium distribution device

- Electricity to connect the remote control

- Maintenance kit (three armor, blade, needle)

- Purchased parts machinery certificates

- Concrete mixer machinery certificate

303 600

- Mounting frame, mobile

- Reinforces points for mixer's mounting

- Installation without foundation

- Cable ducts for electric and pneumatic systems laying

- Mass 2300 kg

1 047 900

- Mounting frame. Installation without foundation

- 2 hoppers for inert materials 4 cu m each

- Pneumatic valves - 2 pieces

- Pneumatic dampers - 2 pieces

- Filter regulator - 1 piece

- Vibrators MVE 3003 - 2 pieces

- Conveyor for inert materials (0-1,000 kg dosage). Belt speed 1.6 m/sec

- Zink plated rollers

- Lined drive drum 7.5 kW

- Drum tension station

- Тензодатчики SBA-2T 2 тонны "CAS" (Ю. Корея) - 4 штуки

- Коробка соединительная "CAS" (Ю. Корея)

- Signal amplifier - weight sensor

476 000

- Mounting frame (powder coating). Weight - 100 kg

- Cement dispenser, dosage - 150 kg (powder coating):

- Two inlet nozzles for screw conveyors (one is covered by a cap)

- Connecting outer sheath with collar clamps

- Overpressure system

- Unloading disc damper ∅200

- Cas BCA100 strain gauges - 3 pcs.

- Signal amplifier - weight sensor

- Pneumatic distributors - 3 pcs.

- Vibrator MVE 300/3 - 1 pc.

- Water dispenser, dosage - 75 liters (powder coating):

- Cas BCA100 strain gauges - 3 pcs.

- CAMOZZI d 50 discharging ball pneumatic damper

- Signal amplifier - weight sensor

- Chemical dispenser additives 10 liters stainless steel:

- Strain gauges Cas BСA100 - 1 pc.

- CAMOZZI d 25 discharging ball pneumatic damper

- Signal amplifier - weight sensor

541 200

- Automatic operation by pressing "one" button

- Recipe storage database for concrete production

- Programmable Logic Controller

- Touch control panel, diagonal 10 inches, wide viewing angle, TFT-screen, 65,000 colors.

- Сontrol panel case protection - IP54

- Control, protection and switching equipment "Schneider Electric", "Omron", "ABB", "Siemens"

- Manual control panel with ingress protection buttons on mimic panel

- Set of diagrams and instruction manual

- Steel wire rope, for fastening screw

- Sleeve for DC

- Hardware for the RBU assembly (490 units)

- Fasteners (turnbuckles, clips, hooks)

- Acid sealant TempPlus

- Hardware for the component (500 units)

- PVC pipe for vodopodvedeniya (size 2)

- Set of cables

- Kit vodopodvedeniya (pipe bends, sleeves, T-joints)

- Power and control cables, protected by metal hose (in mobile plants they are laid in frame)

- Set of locking sensors and executing mechanisms position sensors (skip, mixer's gate, etc.)

1 414 600

- Planetary concrete mixer MPC 375/250

- Planetary mixer drive 9.2 kW

- Replaceable wear-resistant armor made of cast iron with a strength of 500HB

- The sector valve with rubber seal is equipped with a hydraulic drive with the possibility of manual opening

- Water treatment system with water spray nozzles

- Inspection hatches are equipped with an access security system

646 000

- Silo tank (V = 28 m3)

- Mounting frame

- Stairs

- Cover protection enclosure

- Loading pipe d 102 with connection lock

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Machinery certificate

- Calpeda NM 40-12 FA pump assembly for water supply

- Capacity - 550 liters/min

- 1.1 kW power

- Weight - 27 kg with packaging

- Machinery certificate

83 167

- Lattice with section 100x100 (70x70). Cell height 70 mm. Weight 575 kg

39 400

- The pump Calpeda MXH 202E assembled for chemical supply. additives

- Capacity - 80 liters/min

- Power - 0.33 kW

- Weight - 6.9 kg with packaging

- Machinery certificate

233 000

- Spreader RC-6 (Capacity of the spreader is up to 6 tons of cement)

- Mounting frame

- Protective cover of precipitation

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Knife material: high quality tool steel

- Machinery certificate

- Cement filter with vibration cleaning FCS-14, assy

- Filter elements - 9 pieces

- Vibrator - cartridge vibration cleaning system

- Silage setting ring

- Lid

- Shroud

- Machinery certificate

- RMK-2M washer

- Mounting frame

- Service ladder

- Protective cover of precipitation

- Dispenser capacity 2.35 tons of cement

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Knife material: high quality tool steel

- Machinery certificate

- safety valve

- Adjusting ring

- Material - Carbon Steel

- Compound - a collar

- Passport to Safety Valve

277 700

- Screw assembly

- Pipe diameter 168 mm, pipe length 7,500 mm

- Drive: gear motor. Power 5.5 kW

- Inspection window for cleaning and maintenance

- Operational documentation

- Emergency pressure relief valve PV273 assy

- Adjusting ring

- Operational documentation

- Cement level sensor G2 1/2 220V assy in a package

- Adjusting ring

- Operational documentation

- Butterfly valve DN300

- Handle for gate control

- Operational documentation

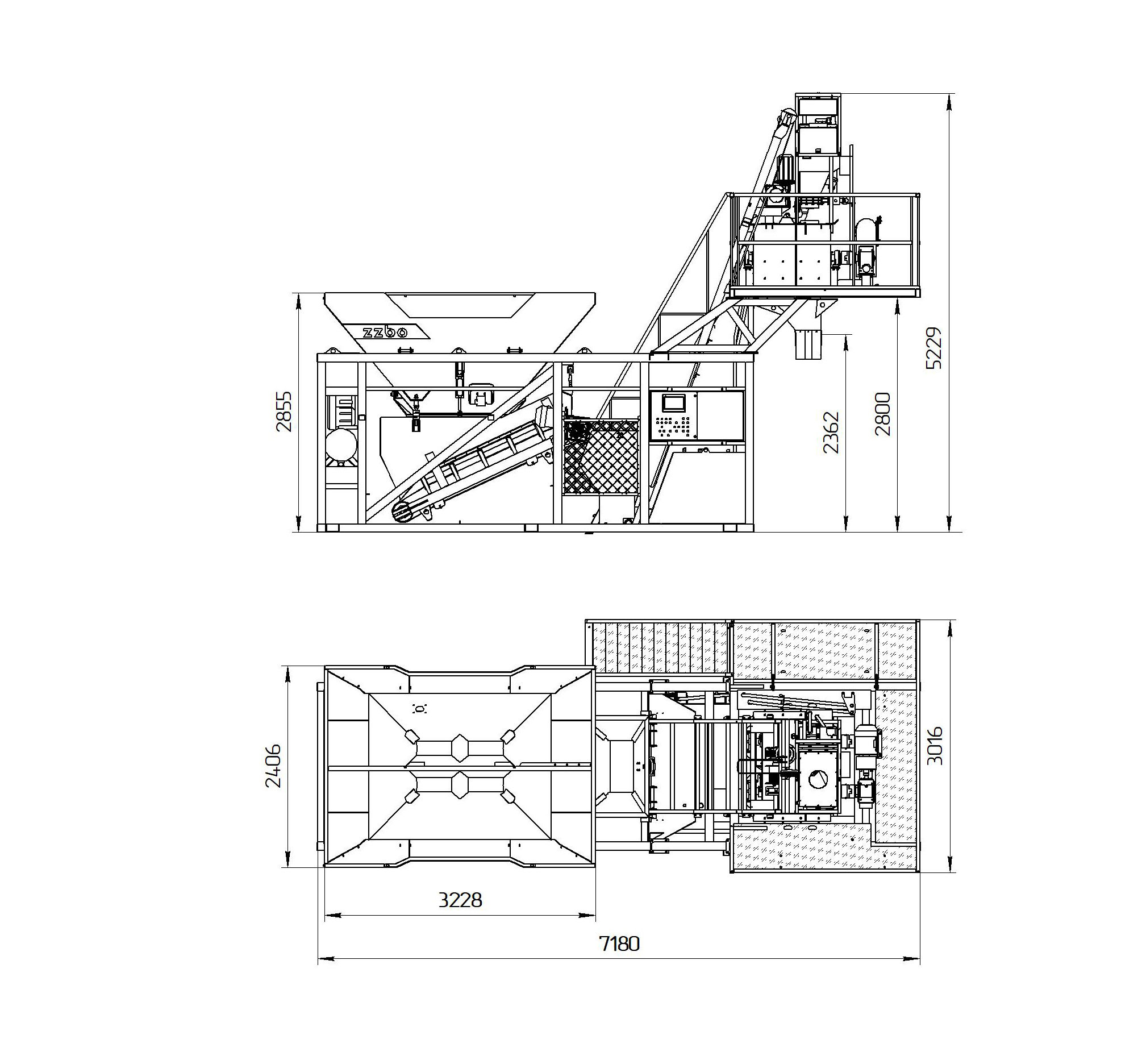

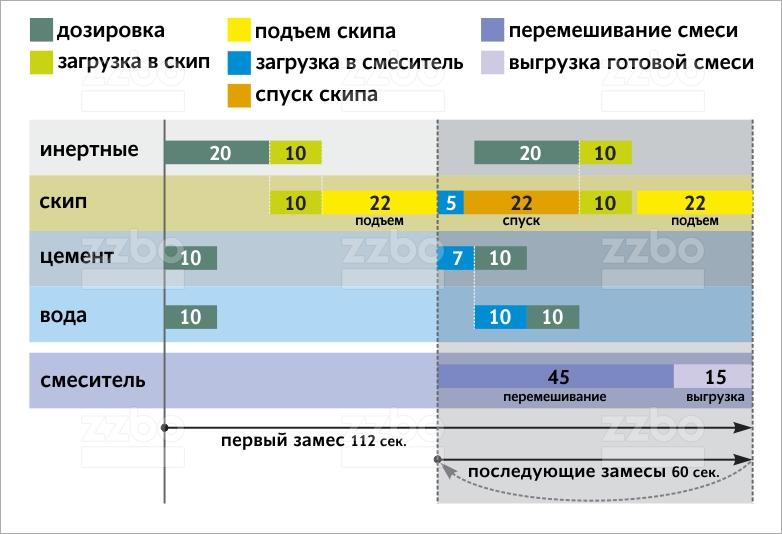

The operation of the ultra-mobile concrete plant COMPACT-25 occurs in a fully automatic mode using the “one button” principle. The operator needs to select the brand of concrete (M50...M500) and its quantity to unload concrete into the receiving hopper, and press the cycle start button. The PAM control panel is located on the support frame. The entire installation is mounted on a frame, which is installed on a flat, dense area, without using a foundation or preparing a skip pit. The BP-2G-375s twin-shaft concrete mixer is installed on a support frame with an unloading height of the finished mixture of 2.8 meters. The concrete mixer is equipped with a skip with a bottom gate for lifting and loading the mixture. The 4 kW winch is equipped with an electric brake.

Designed specifically for the production of concrete products and work as part of vibropress equipment

Для хранения и дозирования инертных: дозирующий комплекс ДКМ-8. Инертные хранятся в бункерах, количество бункеров 2 по 4 куб. метра, общий объем бункеров 8 куб. метров. Под бункерами установлен ленточный конвейер-дозатор, на котором происходит дозирование компонентов, компоненты подаются из бункеров посредством открытия пневмозатворов “Camozzi”(Италия). При наборе необходимой дозы инертных, включается конвейер и инертные подаются в скип, который поднимает компоненты в бетоносмеситель. Все компоненты бетонной смеси (цемент, вода, хим. добавка) подаются и взвешиваются в блоке дозаторов БД-15.

The cement is stored in a special warehouse - cement silo (not included in the basic package). Silos for cement must be selected based on a two-day performance margin. To supply cement from the silo to the cement dispenser, it is necessary to acquire the correct length screw.

Cement silos, silo piping and augers are always in stock in Zlatoust!

С помощью шнека цемента подается в дозатор цемента с пределом взвешивания 150 кг, в котором происходит дозация, по мере необходимости цемент подается в бетоносмеситель. Вода дозируется с помощью дозатора воды объемом 75 литров. Так же в базовую комплектацию входит дозатор хим добавки на 10 литров.

ZZBO is the official dealer of SICOMA concrete mixers in Russia and the CIS!

It is possible to supply a concrete plant with a concrete mixer from the manufacturer SICOMA.

All components of the mixture are mixed; upon achievement of required homogeneity of the mixture, Camozzi pneumatically operated gate is opened, and the mixture is discharged into a concrete mixer lorry or a receiving hopper. Then the cycle is repeated.

The time of one cycle is 45 ... 50 seconds, 0.25 cubic meters are produced in one cycle, so the concrete plant produces 15 ... 25 cubic meters per hour. meters of concrete.

- The time of one cycle is 45 ... 50 seconds, 0.25 cubic meters are produced in one cycle, so the concrete plant produces 15 ... 25 cubic meters per hour. meters of concrete.

- Productivity 25 cubic meters hour

- No foundation or skip pit needed

- Software on its own SCADA system: accounting for the consumption of materials and equipment operation, remote access and control over the work

- Carriage 1 2 eurowaggon (length in the transport position 7 meters)

- Fast deployment and launch in 1 day

Technical Features

- Capacity, cu m per hour 12...25

- Режим работы автомат по принципу "одна кнопка"

- Twin-shaft concrete mixer BP-2G-375s

- Hoppers (number of x capacity, cu m) 2 x 4 = 8

- Pneumatic equipment (Italy) CAMOZZI

- ABAC Pole Position L20P Compressor (Italy) Remeza

- Total power, kW 27,2

- Design summer

- Load of inert materials into the concrete mixer skip

- Sector gate, pneumatic control

- Weight, kg 5,900

- Height, mm 5299

- Width, mm 3016

- Length, mm 7180

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning team

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods