COMPACT-45 Concrete Plant

8 019 400

Enquire conditions

and delivery time

We'll call you back within 15 minutes

Specify your requirements

Send prices and terms of delivery

2 348 000

- BP-2G-1200 Twin-shaft concrete mixer

- Skip (bucket) to load the mixture with the bottom-gate

- Winch for skip lifting with electric brake

- Пневмозатвор "Camozzi" - двойной

- Connection set for pneumatic equipment

- Manual lubrication system: grease press

- Armor shift flake type. Material: cast iron wear 15 mm

- Спицы усиленные (стальное литье) крепление типа "кулак"

- Changeable blades. Material: ЧХ16Н2Т cast iron (chromic high alloy wear-resistant)

- Electricity to connect the remote control

- Maintenance kit (three armor, blade, needle)

- Concrete mixer machinery certificate

937 800

- Mounting frame, mobile. Installation without foundation

- Design enhanced, adapted for the discharge of concrete on the height of 4000 mm

- mixer platform with supporting structures

- Ladders for equipment maintenance

- Fence along the perimeter

- Staircase with handrails

- Funnel for unloading concrete with rubber guide

- Skip ways - rails

- Fastening construction for pipes and electric cables

- Coating: shotblasting, double coloration with drying chamber

- Reinforced and protected operator's cab installation place

2 681 800

- Mounting frame. Installation without foundation

- Three hoppers for inert materials, 12 cu m each (3 x 12)

- Preparation under registers installation for heating inert materials

- Pneumatic valves - 6 pieces

- Pneumatic dampers - 6 pieces

- Filter regulator - 1 piece

- Vibrators MVE 3003 - 6 pieces

- Inert materials belt conveyor (dosage - 0-2500 kg). Belt speed - 1.6 m/sec

- 11 kW lined motorized conveyor drum with smooth-start system (when purchased with control panel)

- Drum tension station

- Тензодатчики SBA-2T 2 тонны "CAS" (Ю. Корея) - 4 штуки

- Коробка соединительная "CAS" (Ю. Корея)

- Signal amplifier - weight sensor

- Software on your own SCADA system complete with a monoblock: accounting for the consumption of materials and equipment operation, remote access and control over the work in the local network

- Automatic operation by pressing "one" button

- Recipe storage database for concrete production

- Programmable Logic Controller

- Сontrol panel case protection - IP54

- Power cabinet case protection - IP54

- Control, protective and switching equipment "Omron", "Siemens"

- Set of diagrams and instruction manual

686 200

- Support frame (powder coated)

- Cement dispenser, dosage - 500 kg (powder coating):

- Three inlet pipes for augers (two are covered with a lid)

- Connecting outer sheath with collar clamps

- Overpressure system

- Unloading disc damper ∅200

- Load cells Cas BSA500 - 3 pcs.

- Signal amplifier - weight sensor

- Pneumatic distributors - 4 pcs.

- Vibrator MVE 300/3 - 1 pc.

- Water dispenser, dosage - 250 liters (powder coating):

- Load cells Cas BSA500 - 3 pcs.

- Water dump pump

- Signal amplifier - weight sensor

- Chemical additives dispenser, dosage - 30 liters, made of stainless steel:

- Strain gauges Cas BСA100 - 2 pcs.

- Ball pneumatic valve ∅25 - 1 pc.

- Ball pneumatic valve ∅50 – 2 pcs.

- Signal amplifier - weight sensor

- Hardware for assembly RBU: metering complex overpass screw silage

- Hardware, accessories

- Wire for screw fixing

- Kit for connecting the database (pnevmotruba, sleeves, bends, RVC 51-70 clamps, duct PVC-5-C-60)

- Limit switch for the database

- Kit vodopodvedeniya (pipe bends, sleeves, T-joints, anchor bolts, brackets)

- Kit RBU pneumatic (air tubing, pnevmotruba, fittings, hardware)

- Set of cables

- Couplings (5 titles)

- compactor

- Acid sealant TempPlus

- Power and control cables, protected by metal hose (in mobile plants they are laid in frame)

- Set of locking sensors and executing mechanisms position sensors (skip, mixer's gate, etc.)

155 000

- Operator's cabin. Sheathed by zinc-coated painted profiled sheeting, finishing accessories, moisture protecting impregnation

- Frame protected against corrosion, 60 mm thick heat insulation

- Sound insulation, protection against rain

- One window (PVC, double glazing), insulated door with lock

- Lighting

- Slinging loops

- Weight - 180 kg

2 298 500

- Planetary concrete mixer MPC 1500

- Mixer drive - 40 kW

- Replaceable wear-resistant armor made of cast iron with a strength of 500HB

- Sector valve with rubber seal equipped with hydraulic drive valve with hydraulic drive and oil station

- Water treatment system with water spray nozzles

- Inspection hatches are equipped with an access security system

2 848 400

- Mounting frame. Installation without foundation

- Bunkers of inert materials 3 pieces of 18 m³ (3 x 18)

- Preparation under registers installation for heating inert materials

- Pneumatic valves - 6 pieces

- Pneumatic dampers - 6 pieces

- Filter regulator - 1 piece

- Vibrators MVE 3003 - 6 pieces

- Inert materials belt conveyor (dosage - 0-3000 kg). Belt speed - 1.6 m/sec

- Lined drive drum motor 18.5 kW with soft start system (when ordered with remote control)

- Drum tension station

- Тензодатчики SBA-3000 "CAS" (Ю. Корея) - 4 штуки

- Коробка соединительная "CAS" (Ю. Корея)

- Signal amplifier - weight sensor

646 000

- Silo tank (V = 28 m3)

- Mounting frame

- Stairs

- Cover protection enclosure

- Loading pipe d 102 with connection lock

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Machinery certificate

39 400

- The pump Calpeda MXH 202E assembled for chemical supply. additives

- Capacity - 80 liters/min

- Power - 0.33 kW

- Weight - 6.9 kg with packaging

- Machinery certificate

- Lattice on the section of the bunker 70x70 for DK-36 (DK-54) - RBU-2G-60AK-05.08.000

- Lattice on the section of the bunker 100x100 for DK-36 (DK-54) - RBU-2G-60AK-05.08.000-01

28 260

- Aeration jet - 8 pcs

- Assembly kit (fittings, tees, polyurethane tube, bracket, nipple, gasket, plug)

- Filter regulator - 1 pc.

- Ball valve G1/4 - 2pcs

- Axial pressure gauge, 0-2.5 bar - 1 pc.

- 3/2 distributor G1/4, unilateral. - 1 PC

- Solenoid - 1 pc

- Solenoid connector - 1 pc

1 376 000

- Heat generator TGV-250 basic version

- Fan assembled with an electric motor type Fan VR 140-15 No. 8 version 1, 22 kW, 3000 rpm, left. 270. 380/660

- The automation system (control cabinet)

- chimney section

- Schild in the control cabinet

- Passport and Manual

1 029 700

- Silo Tank (V = 50 m3): cover - 4 sectors, cylindrical section - 12 sectors, large cone - 4 sectors, small cone

- Mounting frame

- Stairs

- Cover protection enclosure - 11 sectors

- Loading pipe d 102 with connection lock

- Inspection hatch (Viewing window for inspection and cleaning of the cone)

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Frame for transportation

- Hardware for the assembly of a silo

- Polyurethane sealant Soudaflex FC 40 gray 600ml - 9 tubes

- Machinery certificate

- Emergency pressure relief valve PV273 assy

- Adjusting ring

- Operational documentation

- Butterfly valve DN300

- Handle for gate control

- Operational documentation

- Cement level sensor G2 1/2 220V assy in a package

- Adjusting ring

- Operational documentation

- safety valve

- Adjusting ring

- Material - Carbon Steel

- Compound - a collar

- Passport to Safety Valve

1 155 000

- Silo bank (V=50m³)

- Mounting frame

- Stairs

- Cover protection enclosure

- Loading pipe d 102 with connection lock

- Connecting flanges for installation cement filter emergency valve, level sensors, aeration and vibrator

- Shot peening prior to application to the extent Sa 2 1/2 GOST P ISO 8501-1-2014

- Anti-corrosion protection is made with a two-component primer-enamel PentriProtect PUR 700 based on polyurethane-acrylic resin in the ATIS spray booth

- Machinery certificate

347 800

- Auger assembly

- Pipe Diameter 219 mm Pipe Length 11 500 mm

- Drive: motor-reducer. Power 11 kW

- Inspection window for cleaning and maintenance

- Operational documentation

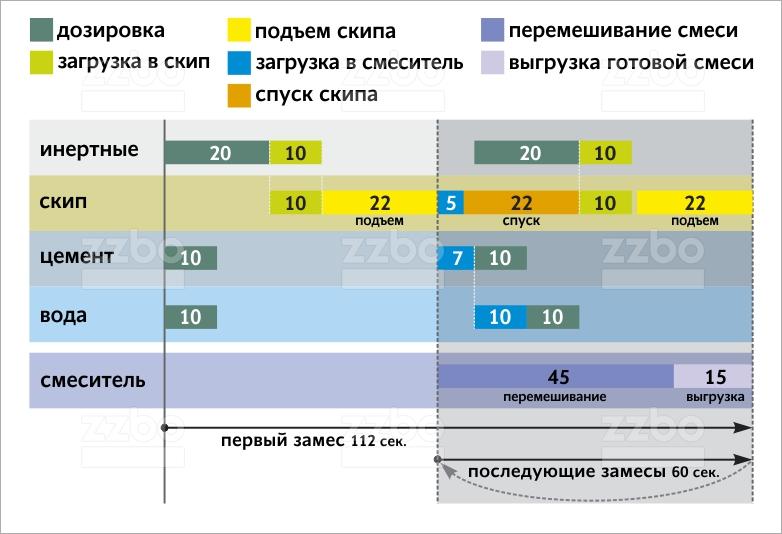

The work of the concrete plant COMPACT-45 takes place in automatic mode in accordance with the single button principle. The operator needs to choose grade of concrete (M50 ... M500) and its quantity to be loaded into the mixer truck, press the “cycle start” button.

PA-3.0 SCADA-5.0 control panel with monoblock located in the operator's cabin, which can be installed to work in two different positions: 1) transport (built into the frame), or 2) next to the concrete plant, any place convenient for installation.

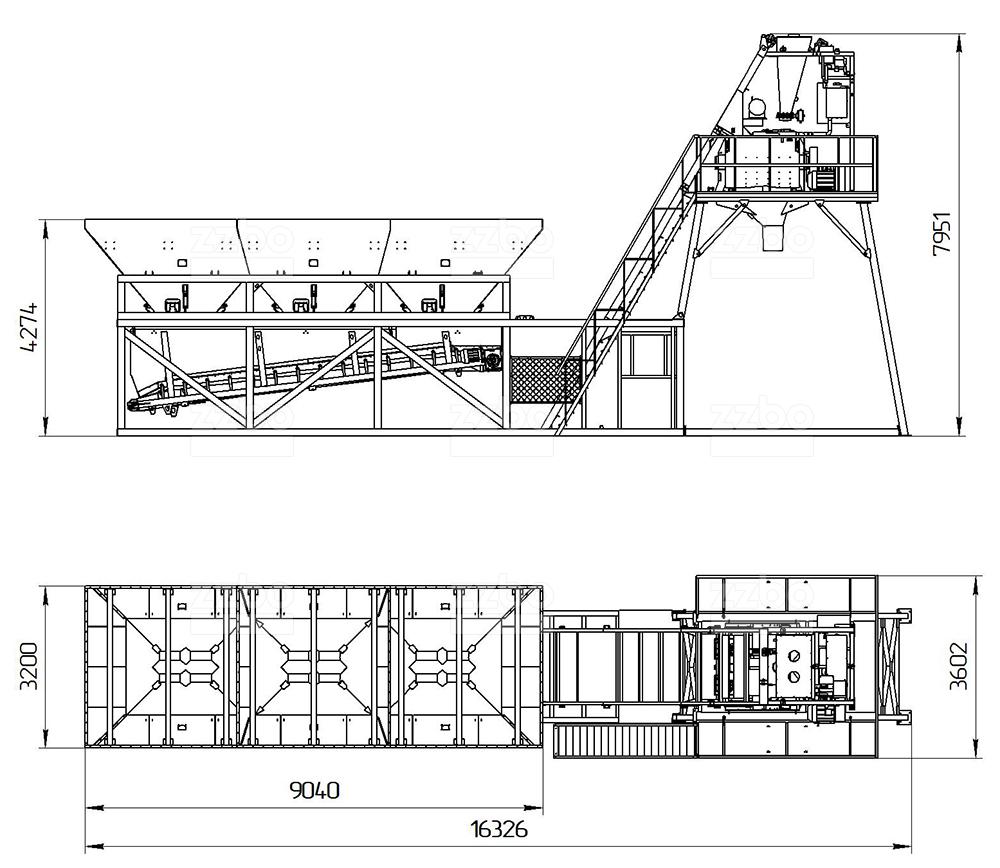

All components of the plant are mounted on a frame, which is installed on a flat area, No foundation or skip pit needed.

Twin-shaft concrete mixer is mounted on a platform. Discharge height - 4 m. The concrete mixer is equipped with a skip for mixture hoisting and feeding.

DKM-36 batching complex is used for inert materials storage and batching. There are three hoppers of 12 cu m each. Total capacity is 36 cu m. . A dosing belt conveyor is installed under the bunkers, on which components are dispensed; the components are supplied from the bunkers by opening pneumatic valves. When the required dose of inerts has been collected, the conveyor is turned on and the inerts are fed into a skip, which lifts the components into the concrete mixer.

Cement is stored in a special warehouse - a cement silo (not included in the basic package). Silos for cement must be selected the rate of two daily stock performance. For feeding cement from a cement silo dispenser must acquire the correct length screw.

Cement silos, silo piping and augers are always in stock at the ZZBO warehouse in Zlatoust!

Cement, water and chemical additives are batched in BD-45 block if dispensers. Cement is batched in cement dispenser with maximum dosage 450 kg.

Water and chem. additives are dosed with dispenser unit BD-45.

ZZBO is the official dealer of SICOMA concrete mixers in Russia and the CIS!

It is possible to supply a concrete plant with a concrete mixer from the manufacturer SICOMA.

There is a mixing of all components of the mixture, after obtaining the necessary homogeneity of the mixture, the pneumatic gate opens and the mixture is unloaded into a concrete mixer truck or a receiving hopper.

One cycle lasts for 55-60 seconds , in one cycle 0.8 cubic meters of the finished mixture is produced.

- Capacity 45 cu m per hour

- No foundation or skip pit needed

- Twin-shaft concrete mixer

- Software on its own SCADA system complete with a monoblock: accounting for the consumption of materials and equipment operation, remote access and control over the work

- Transportation 2 euro trailers or 40-foot containers

- Quick deployment and start-up - within one working day

Technical Features

- Capacity, cu m per hour 35...45

- Режим работы автомат по принципу "одна кнопка"

- Twin-shaft concrete mixer BP-2G-1200s

- Hoppers (number of x capacity, cu m) 3 x 12 = 36

- Silo capacity (optional), tons from 22

- Design summer

- Load of inert materials into the concrete mixer skip

- Total power, kW 70

- Sector gate, pneumatic control

- Weight, kg 20,000

- Height, mm 7951

- Width, mm 3602

- Length, mm 16326

Quality

certificates

Products

in stock

Individual configuration

with prices for each item

Mobile

commissioning team

available

Worldwide

delivery

in trucks or containers

Geography of supplies 2011-2024

Own production, in-stock products and

professional team allow us guarantee

most competitive prices, shortest

possible delivery time and high-quality goods